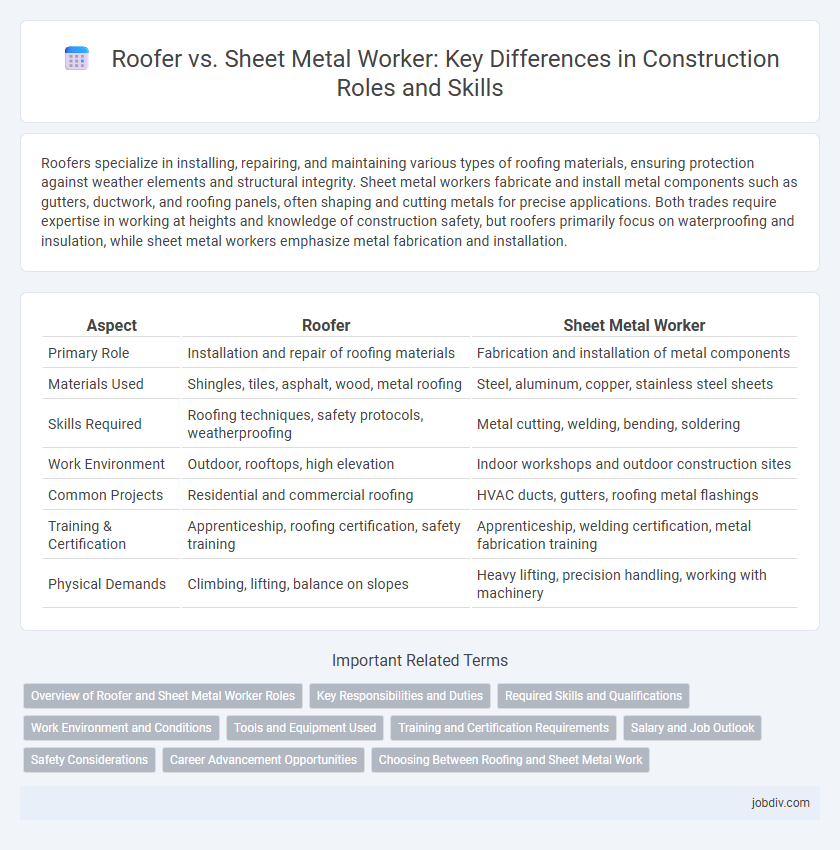

Roofers specialize in installing, repairing, and maintaining various types of roofing materials, ensuring protection against weather elements and structural integrity. Sheet metal workers fabricate and install metal components such as gutters, ductwork, and roofing panels, often shaping and cutting metals for precise applications. Both trades require expertise in working at heights and knowledge of construction safety, but roofers primarily focus on waterproofing and insulation, while sheet metal workers emphasize metal fabrication and installation.

Table of Comparison

| Aspect | Roofer | Sheet Metal Worker |

|---|---|---|

| Primary Role | Installation and repair of roofing materials | Fabrication and installation of metal components |

| Materials Used | Shingles, tiles, asphalt, wood, metal roofing | Steel, aluminum, copper, stainless steel sheets |

| Skills Required | Roofing techniques, safety protocols, weatherproofing | Metal cutting, welding, bending, soldering |

| Work Environment | Outdoor, rooftops, high elevation | Indoor workshops and outdoor construction sites |

| Common Projects | Residential and commercial roofing | HVAC ducts, gutters, roofing metal flashings |

| Training & Certification | Apprenticeship, roofing certification, safety training | Apprenticeship, welding certification, metal fabrication training |

| Physical Demands | Climbing, lifting, balance on slopes | Heavy lifting, precision handling, working with machinery |

Overview of Roofer and Sheet Metal Worker Roles

Roofers specialize in installing, repairing, and maintaining various types of roofing systems, including asphalt shingles, metal, and tile, ensuring waterproof and weather-resistant structures. Sheet metal workers fabricate, install, and maintain metal components such as ducts, roofing panels, and flashing, playing a crucial role in ventilation, roofing, and architectural detailing. Both professions require knowledge of safety standards, materials, and blueprints, with roofers focusing on exterior surfaces and sheet metal workers handling custom metal fabrication and installation.

Key Responsibilities and Duties

Roofers specialize in installing, repairing, and maintaining various roofing materials such as shingles, tiles, and asphalt to ensure weatherproofing and structural integrity. Sheet metal workers fabricate, install, and repair metal components including ductwork, roofing panels, and flashing, focusing on precise metal cutting and shaping. Both roles require knowledge of safety protocols, but roofers primarily address waterproofing challenges while sheet metal workers concentrate on metal fabrication and installation in construction projects.

Required Skills and Qualifications

Roofers require expertise in installing, repairing, and maintaining various roofing materials such as shingles, tiles, and asphalt, along with strong physical stamina and proficiency in using hand and power tools. Sheet metal workers must have advanced skills in fabricating, cutting, and shaping metal sheets for roofing, gutters, and HVAC systems, coupled with knowledge of blueprints and welding techniques. Both trades demand safety training and the ability to work at heights, but sheet metal workers often need more specialized training in metallurgy and precision measuring.

Work Environment and Conditions

Roofers typically work outdoors on residential and commercial buildings, often exposed to varying weather conditions such as heat, cold, and rain, requiring physical endurance and safety precautions for heights. Sheet metal workers operate both indoors and outdoors, fabricating and installing metal roofing, ductwork, and siding in environments that may include construction sites, factories, and workrooms, often involving heavy lifting and precise tools handling. Both trades demand strict adherence to safety regulations due to risks like falls, sharp materials, and machinery.

Tools and Equipment Used

Roofers primarily use roofing hammers, nail guns, roofing shovels, utility knives, and chalk lines to install shingles, underlayment, and flashing. Sheet metal workers rely on metal shears, bending brakes, seamers, welding machines, and rivet guns to cut, shape, and join metal roofing and ductwork. Both trades require safety equipment such as harnesses, gloves, and helmets to ensure protection during high and hazardous work environments.

Training and Certification Requirements

Roofers typically undergo apprenticeships lasting three to four years, combining on-the-job training with safety and installation courses, while certification such as the Occupational Safety and Health Administration (OSHA) training is highly recommended. Sheet metal workers complete apprenticeship programs of about four to five years that cover blueprint reading, metal forming, and welding, often earning certification through the National Center for Construction Education and Research (NCCER). Both trades require strong knowledge of safety standards and hands-on skills, but sheet metal workers generally receive more technical instruction related to metal fabrication and HVAC systems.

Salary and Job Outlook

Roofers earn a median annual salary of approximately $48,000, while sheet metal workers average around $51,000, reflecting a slight wage advantage in metalwork trades. Employment projections indicate a 6% growth for roofers and 7% for sheet metal workers over the next decade, driven by infrastructure upgrades and increased construction activity. Demand for sheet metal workers remains strong due to specialization in HVAC systems and architectural metalwork, whereas roofers face steady demand rooted in residential and commercial roofing maintenance.

Safety Considerations

Roofers face significant safety risks such as falls from heights, exposure to extreme weather, and handling heavy materials, necessitating rigorous use of fall protection systems and personal protective equipment (PPE). Sheet metal workers encounter hazards from sharp edges, heavy lifting, and operating powered tools, requiring gloves, eye protection, and proper ergonomic practices to prevent injuries. Both professions mandate strict adherence to Occupational Safety and Health Administration (OSHA) regulations and continuous safety training to minimize workplace accidents.

Career Advancement Opportunities

Roofers often advance to supervisory roles or start their own roofing companies by gaining experience in specialized roofing systems and certifications in safety standards. Sheet metal workers can progress to project managers, estimators, or business owners by developing expertise in HVAC systems, custom fabrications, and advanced metalworking technologies. Both careers offer pathways to skilled trades leadership, but sheet metal workers typically have broader opportunities in industrial and commercial sectors due to their diverse skill set.

Choosing Between Roofing and Sheet Metal Work

Choosing between roofing and sheet metal work involves understanding the distinct skills and materials used in each trade: roofers specialize in installing and repairing shingles, tiles, and waterproof membranes, while sheet metal workers fabricate and install metal components such as gutters, HVAC ductwork, and roofing panels. Consider the specific job site demands, physical requirements, and expertise with tools like nail guns for roofing or bending machines for sheet metal to determine the best fit. Career growth potential and safety protocols also differ, with sheet metal work requiring precision metal fabrication skills and roofing emphasizing weatherproofing and structural integrity.

Roofer vs Sheet Metal Worker Infographic

jobdiv.com

jobdiv.com