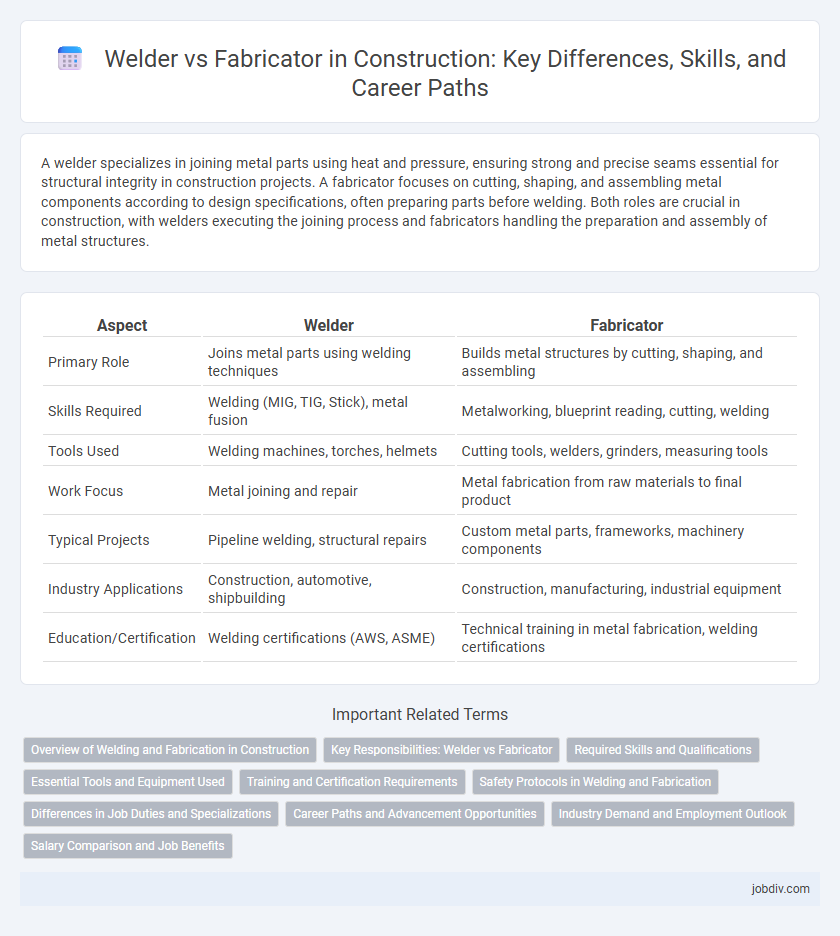

A welder specializes in joining metal parts using heat and pressure, ensuring strong and precise seams essential for structural integrity in construction projects. A fabricator focuses on cutting, shaping, and assembling metal components according to design specifications, often preparing parts before welding. Both roles are crucial in construction, with welders executing the joining process and fabricators handling the preparation and assembly of metal structures.

Table of Comparison

| Aspect | Welder | Fabricator |

|---|---|---|

| Primary Role | Joins metal parts using welding techniques | Builds metal structures by cutting, shaping, and assembling |

| Skills Required | Welding (MIG, TIG, Stick), metal fusion | Metalworking, blueprint reading, cutting, welding |

| Tools Used | Welding machines, torches, helmets | Cutting tools, welders, grinders, measuring tools |

| Work Focus | Metal joining and repair | Metal fabrication from raw materials to final product |

| Typical Projects | Pipeline welding, structural repairs | Custom metal parts, frameworks, machinery components |

| Industry Applications | Construction, automotive, shipbuilding | Construction, manufacturing, industrial equipment |

| Education/Certification | Welding certifications (AWS, ASME) | Technical training in metal fabrication, welding certifications |

Overview of Welding and Fabrication in Construction

Welding in construction involves joining metal parts through high heat to create strong, permanent bonds essential for structural integrity. Fabrication encompasses cutting, shaping, and assembling metal components to produce construction elements such as beams, columns, and frames tailored to project specifications. Both welding and fabrication are critical processes that ensure durability and precision in building infrastructure.

Key Responsibilities: Welder vs Fabricator

Welders specialize in joining metal parts using techniques like MIG, TIG, and arc welding, ensuring strong, durable seams for structural integrity. Fabricators focus on interpreting blueprints, cutting, shaping, and assembling metal components into finished products or frameworks. Both roles require precision and knowledge of metallurgy, but welders primarily execute welding tasks while fabricators manage broader assembly and preparation processes.

Required Skills and Qualifications

Welders require proficiency in welding techniques such as MIG, TIG, and stick welding, along with knowledge of reading blueprints and adherence to safety standards. Fabricators need advanced skills in metal cutting, shaping, and assembling, often using tools like plasma cutters, grinders, and CNC machines, combined with strong blueprint interpretation and material specification knowledge. Both roles demand certifications such as AWS (American Welding Society) for welders and specialized fabrication certifications to ensure industry compliance and quality standards.

Essential Tools and Equipment Used

Welders primarily use equipment such as welding machines, electrodes, protective helmets, and gloves to fuse metals together, ensuring strong and precise joints. Fabricators rely on tools like cutting torches, grinders, metal shears, and bending machines to shape and assemble metal components into final structures. Both roles require measuring instruments and safety gear, but welders focus more on joining technologies while fabricators emphasize shaping and assembly tools.

Training and Certification Requirements

Welders require specialized training in welding techniques, metallurgy, and safety protocols, often earning certifications like AWS Certified Welder to validate proficiency. Fabricators need broader training encompassing blueprint reading, material handling, and fabrication processes, with certifications such as Certified Fabricator or specific industry-related qualifications enhancing their expertise. Both roles demand adherence to rigorous training standards and ongoing certification to meet construction industry safety and quality requirements.

Safety Protocols in Welding and Fabrication

Welding and fabrication demand strict adherence to safety protocols, including the use of personal protective equipment (PPE) such as helmets, gloves, and flame-resistant clothing to prevent burns and exposure to harmful fumes. Proper ventilation and regular equipment inspections are critical to minimize risks of toxic gas inhalation and electrical hazards. Compliance with OSHA standards and continuous safety training ensures both welders and fabricators maintain a secure work environment.

Differences in Job Duties and Specializations

Welders primarily focus on joining metal parts using techniques like MIG, TIG, and stick welding to create strong, permanent bonds for structures and machinery. Fabricators specialize in interpreting blueprints, cutting, shaping, and assembling metal components into finished products or structural frameworks, often involving more detailed metalworking skills and precision. While welders concentrate on the welding process itself, fabricators oversee the broader production process, including material preparation and assembly.

Career Paths and Advancement Opportunities

Welders specialize in joining metal components using techniques such as MIG, TIG, and arc welding, often advancing into roles like inspection or welding supervision through certifications like AWS. Fabricators design and assemble metal structures from blueprints, with career growth leading to positions in project management or engineering due to their broad technical skills. Both career paths offer advancement opportunities, but fabricators generally have a wider scope for leadership roles and specialization in various metalworking sectors.

Industry Demand and Employment Outlook

The construction industry shows strong demand for both welders and fabricators, driven by infrastructure projects and industrial expansion. Welders often have higher employment opportunities due to their specialized skills in joining metals, critical for structural integrity in buildings and pipelines. Fabricators, skilled in assembling metal components and reading blueprints, maintain steady employment prospects in manufacturing and custom construction projects.

Salary Comparison and Job Benefits

Welders typically earn an average annual salary ranging from $40,000 to $60,000, while fabricators often see salaries between $45,000 and $65,000 depending on experience and specialization. Fabricators generally receive more comprehensive job benefits, including health insurance, retirement plans, and paid leave, due to their broader role in assembling and constructing metal structures. Both positions offer opportunities for overtime pay and skill-based bonuses, but fabricators may have higher earning potential with advanced certifications and supervisory responsibilities.

Welder vs Fabricator Infographic

jobdiv.com

jobdiv.com