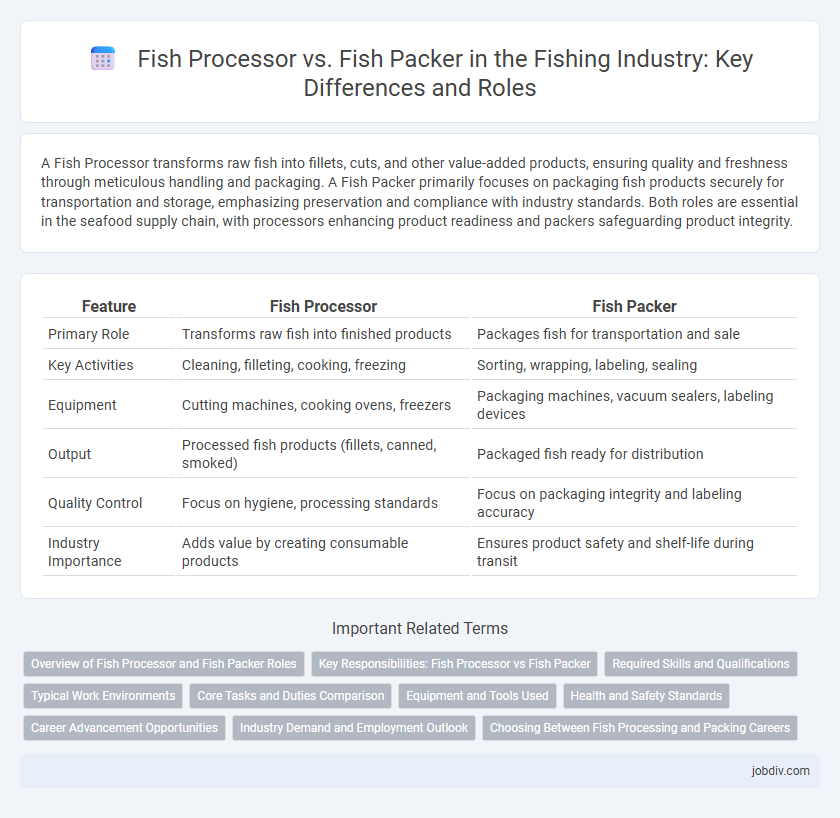

A Fish Processor transforms raw fish into fillets, cuts, and other value-added products, ensuring quality and freshness through meticulous handling and packaging. A Fish Packer primarily focuses on packaging fish products securely for transportation and storage, emphasizing preservation and compliance with industry standards. Both roles are essential in the seafood supply chain, with processors enhancing product readiness and packers safeguarding product integrity.

Table of Comparison

| Feature | Fish Processor | Fish Packer |

|---|---|---|

| Primary Role | Transforms raw fish into finished products | Packages fish for transportation and sale |

| Key Activities | Cleaning, filleting, cooking, freezing | Sorting, wrapping, labeling, sealing |

| Equipment | Cutting machines, cooking ovens, freezers | Packaging machines, vacuum sealers, labeling devices |

| Output | Processed fish products (fillets, canned, smoked) | Packaged fish ready for distribution |

| Quality Control | Focus on hygiene, processing standards | Focus on packaging integrity and labeling accuracy |

| Industry Importance | Adds value by creating consumable products | Ensures product safety and shelf-life during transit |

Overview of Fish Processor and Fish Packer Roles

Fish processors transform raw fish into packaged, ready-to-sell products through cleaning, filleting, and freezing, ensuring quality and safety standards. Fish packers specialize in packaging processed fish, using appropriate materials and labeling for distribution and retail. Both roles are essential in maintaining the seafood supply chain's efficiency and product integrity.

Key Responsibilities: Fish Processor vs Fish Packer

Fish processors are responsible for cleaning, filleting, and preparing fish for market or further processing, ensuring quality control and adherence to food safety standards. Fish packers focus on packaging the processed fish, labeling, and arranging products for shipment, maintaining proper storage conditions to preserve freshness. Both roles require attention to detail and knowledge of handling seafood to maintain product integrity.

Required Skills and Qualifications

Fish processors require skills in quality control, filleting, deboning, and knowledge of food safety regulations to ensure product integrity. Fish packers must possess attention to detail, ability to handle packaging machinery, and knowledge of proper storage techniques to maintain fish freshness during distribution. Both roles demand physical stamina, adherence to hygiene standards, and familiarity with temperature control protocols to comply with industry standards.

Typical Work Environments

Fish processors typically work in seafood processing plants where fish are cleaned, filleted, and packaged under strict hygiene and temperature-controlled conditions. Fish packers usually operate in cold storage facilities or packing stations, focusing on sorting, packing, and labeling fish products for distribution and retail. Both roles require adherence to safety protocols and often involve working in wet, cold environments to maintain product quality.

Core Tasks and Duties Comparison

Fish processors primarily handle the cleaning, filleting, and packaging of fish products to ensure quality and safety standards are met, involving tasks such as gutting, scaling, and freezing. Fish packers focus on the organization, labeling, and sealing of fish products for transportation and retail distribution, ensuring proper storage conditions and accurate inventory management. Both roles require attention to detail and compliance with regulatory guidelines, but processors engage more in product preparation, while packers specialize in product preservation and shipment readiness.

Equipment and Tools Used

Fish processors utilize specialized filleting machines, automated cutting tables, and deboning tools designed to enhance precision and efficiency in converting raw fish into market-ready products. Fish packers primarily rely on vacuum sealers, weighing scales, and ice flaking machines to ensure proper packaging, preservation, and shipment of processed fish products. Both roles demand equipment tailored to maintain hygiene standards and minimize product contamination during handling.

Health and Safety Standards

Fish processors enforce strict health and safety standards by implementing sanitation protocols, quality control checks, and proper handling techniques to prevent contamination and ensure product safety. Fish packers focus on maintaining hygiene during packaging by using sterile equipment, correct temperature controls, and secure sealing methods to preserve freshness and prevent microbial growth. Both roles prioritize compliance with regulatory guidelines such as HACCP (Hazard Analysis and Critical Control Points) to protect consumer health throughout the supply chain.

Career Advancement Opportunities

Fish processors typically start with hands-on roles in cleaning and filleting, gaining technical skills essential for product quality control and management positions. Fish packers often focus on packaging logistics and efficiency, which can lead to supervisory roles in distribution and supply chain management. Career advancement in fish processing generally offers more pathways into quality assurance, production planning, and regulatory compliance compared to fish packing.

Industry Demand and Employment Outlook

The fish processing industry shows robust demand driven by increasing global seafood consumption, requiring skilled fish processors for tasks like cleaning, filleting, and packaging to ensure product quality. Fish packers focus on the efficient packing and preservation of seafood for distribution, with employment opportunities growing in regions with strong export markets and large commercial fisheries. Industry trends indicate fish processors may experience higher demand due to technological advancements in processing methods, while fish packers benefit from expanded cold chain logistics and retail seafood packaging innovations.

Choosing Between Fish Processing and Packing Careers

Choosing between fish processing and fish packing careers depends on skill sets and interests, as fish processors handle filleting, cleaning, and preparing fish for sale, requiring precision and knowledge of hygiene standards. Fish packers focus on the packaging, labeling, and freezing of fish products, emphasizing speed and efficiency to maintain freshness during distribution. Both roles are crucial in the seafood supply chain, offering opportunities in commercial fishing hubs and seafood processing plants.

Fish Processor vs Fish Packer Infographic

jobdiv.com

jobdiv.com