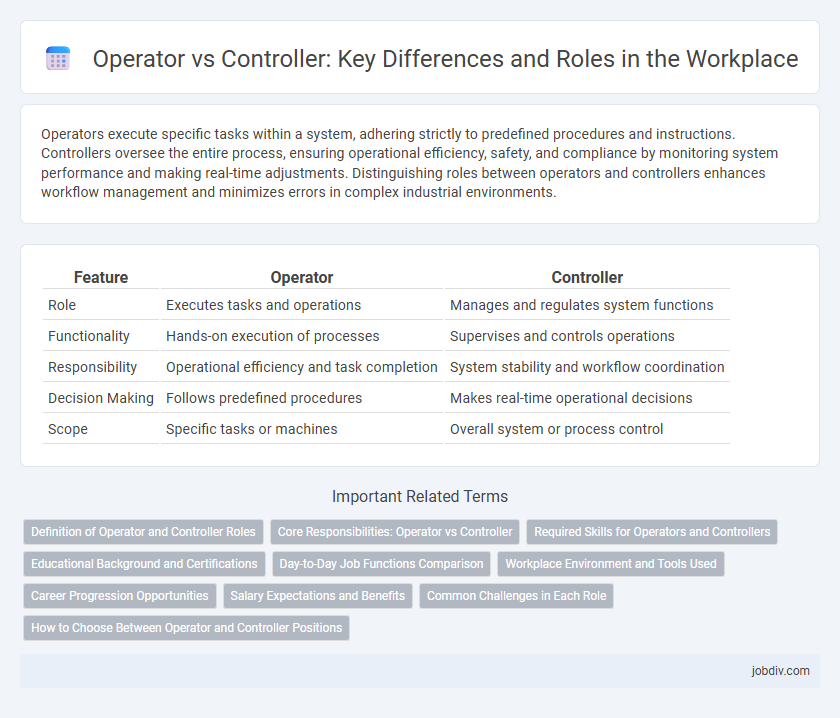

Operators execute specific tasks within a system, adhering strictly to predefined procedures and instructions. Controllers oversee the entire process, ensuring operational efficiency, safety, and compliance by monitoring system performance and making real-time adjustments. Distinguishing roles between operators and controllers enhances workflow management and minimizes errors in complex industrial environments.

Table of Comparison

| Feature | Operator | Controller |

|---|---|---|

| Role | Executes tasks and operations | Manages and regulates system functions |

| Functionality | Hands-on execution of processes | Supervises and controls operations |

| Responsibility | Operational efficiency and task completion | System stability and workflow coordination |

| Decision Making | Follows predefined procedures | Makes real-time operational decisions |

| Scope | Specific tasks or machines | Overall system or process control |

Definition of Operator and Controller Roles

Operator roles focus on executing specific tasks and managing equipment or system functions according to established procedures, ensuring smooth daily operations. Controller roles involve monitoring, regulating, and adjusting system parameters or processes to maintain optimal performance and safety standards. Both roles require technical expertise but differ in scope, with operators handling direct control and controllers overseeing system stability and compliance.

Core Responsibilities: Operator vs Controller

Operators manage day-to-day machinery functions, ensuring operational efficiency and safety compliance, while Controllers oversee financial and administrative controls, maintaining budget accuracy and regulatory adherence. Operators are responsible for monitoring system performance and executing immediate troubleshooting, whereas Controllers focus on strategic planning, financial reporting, and risk management. Effective collaboration between Operators and Controllers enhances overall organizational performance by aligning operational activities with financial objectives.

Required Skills for Operators and Controllers

Operators require technical proficiency in machinery operation, real-time problem-solving abilities, and thorough knowledge of safety protocols to ensure efficient and secure system functionality. Controllers must excel in data analysis, regulatory compliance, and resource management to optimize process flows and maintain operational standards. Both roles demand strong communication skills and attention to detail to effectively coordinate tasks and sustain organizational performance.

Educational Background and Certifications

Operators typically possess a technical diploma or an associate degree in fields like industrial technology or process control, emphasizing hands-on skills and equipment operation. Controllers often require a bachelor's degree in engineering, automation, or computer science, supplemented by certifications such as Certified Control Systems Technician (CCST) or Project Management Professional (PMP). Advanced certifications in instrumentation and control, like ISA Certified Automation Professional (CAP), enhance a controller's expertise in system design and process optimization.

Day-to-Day Job Functions Comparison

Operators primarily manage the real-time functioning of machinery and equipment, ensuring operational efficiency and addressing immediate technical issues during shifts. Controllers focus on overseeing system performance through data analysis, maintaining process control parameters, and implementing operational strategies to optimize productivity. Both roles collaborate closely to balance hands-on machine operation with systematic process regulation for seamless production workflows.

Workplace Environment and Tools Used

Operators primarily interact with physical machinery and equipment on the workplace floor, utilizing tools such as hand-held devices, control panels, and diagnostic instruments to manage and monitor production processes. Controllers operate in control rooms equipped with advanced software systems, including SCADA and PLC interfaces, enabling real-time data analysis, process automation, and decision-making for efficient workflow management. The workplace environment for operators emphasizes hands-on tasks and direct machine interaction, whereas controllers engage in supervisory roles within technology-driven settings to ensure operational stability and safety.

Career Progression Opportunities

Operators typically begin their careers by mastering equipment and process controls, gaining hands-on experience that lays the foundation for advancement. Controllers often require advanced technical skills and oversee complex system integrations, positioning them for leadership roles in process management and operational strategy. Career progression from operator to controller is common, supported by targeted training and certifications in automation and control systems.

Salary Expectations and Benefits

Operators generally earn slightly lower salaries compared to Controllers, with average annual wages of $40,000 to $55,000 versus $70,000 to $90,000, reflecting differences in responsibility and required expertise. Controllers often receive more comprehensive benefits packages, including performance bonuses, retirement plans, and advanced healthcare coverage, which align with their critical role in organizational management. Salary expectations for Operators tend to increase with experience but remain below the financial compensation typically awarded to Controllers due to the latter's strategic decision-making functions.

Common Challenges in Each Role

Operators often face challenges related to maintaining system uptime and responding swiftly to real-time issues, demanding strong troubleshooting skills under pressure. Controllers encounter difficulties in achieving precise data accuracy and regulatory compliance, requiring meticulous attention to detail and thorough analytical capabilities. Both roles require effective communication and coordination to ensure seamless operational continuity and organizational efficiency.

How to Choose Between Operator and Controller Positions

Choosing between operator and controller positions depends on your technical skills and career goals within industrial or manufacturing environments. Operators typically handle hands-on machine operation and routine maintenance, requiring mechanical aptitude and attention to detail. Controllers focus on system monitoring and process control, demanding strong analytical abilities and familiarity with control software and automation systems.

Operator vs Controller Infographic

jobdiv.com

jobdiv.com