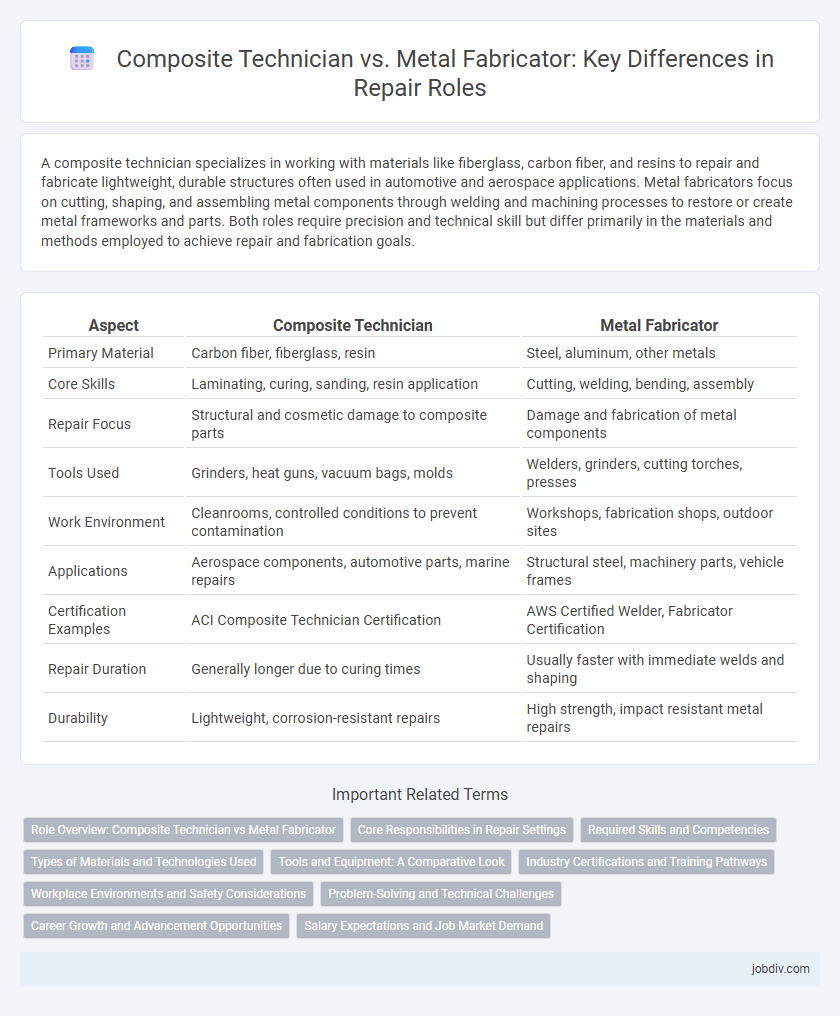

A composite technician specializes in working with materials like fiberglass, carbon fiber, and resins to repair and fabricate lightweight, durable structures often used in automotive and aerospace applications. Metal fabricators focus on cutting, shaping, and assembling metal components through welding and machining processes to restore or create metal frameworks and parts. Both roles require precision and technical skill but differ primarily in the materials and methods employed to achieve repair and fabrication goals.

Table of Comparison

| Aspect | Composite Technician | Metal Fabricator |

|---|---|---|

| Primary Material | Carbon fiber, fiberglass, resin | Steel, aluminum, other metals |

| Core Skills | Laminating, curing, sanding, resin application | Cutting, welding, bending, assembly |

| Repair Focus | Structural and cosmetic damage to composite parts | Damage and fabrication of metal components |

| Tools Used | Grinders, heat guns, vacuum bags, molds | Welders, grinders, cutting torches, presses |

| Work Environment | Cleanrooms, controlled conditions to prevent contamination | Workshops, fabrication shops, outdoor sites |

| Applications | Aerospace components, automotive parts, marine repairs | Structural steel, machinery parts, vehicle frames |

| Certification Examples | ACI Composite Technician Certification | AWS Certified Welder, Fabricator Certification |

| Repair Duration | Generally longer due to curing times | Usually faster with immediate welds and shaping |

| Durability | Lightweight, corrosion-resistant repairs | High strength, impact resistant metal repairs |

Role Overview: Composite Technician vs Metal Fabricator

Composite Technicians specialize in working with advanced composite materials such as carbon fiber and fiberglass, performing tasks like layup, curing, and finishing to create lightweight, durable components. Metal Fabricators focus on shaping, cutting, welding, and assembling metal parts to construct or repair structures and equipment, using techniques like MIG, TIG welding, and plasma cutting. Both roles require precision and technical skill, but Composite Technicians handle synthetic materials with specific chemical properties, while Metal Fabricators primarily work with various metals and alloys.

Core Responsibilities in Repair Settings

Composite Technicians specialize in repairing and restoring advanced composite materials such as fiberglass, carbon fiber, and Kevlar, focusing on precision layering, curing processes, and structural integrity in aerospace and automotive repair settings. Metal Fabricators handle the cutting, shaping, and welding of metal components, ensuring alignment, strength, and corrosion resistance primarily in industrial and construction repairs. Both roles require expertise in interpreting technical drawings and specifications, but Composite Technicians prioritize material bonding and finish quality while Metal Fabricators emphasize metal joining techniques and durability.

Required Skills and Competencies

Composite technicians require expertise in materials like carbon fiber and fiberglass, proficiency in layering and curing processes, and knowledge of safety protocols related to composite resins. Metal fabricators need strong skills in welding techniques, metal cutting, shaping, and interpreting blueprints to create precise metal structures. Both roles demand attention to detail, manual dexterity, and the ability to read technical drawings, but composite technicians focus more on chemical processes while metal fabricators specialize in mechanical fabrication.

Types of Materials and Technologies Used

Composite technicians specialize in working with advanced materials such as carbon fiber, fiberglass, and resin systems, utilizing techniques like lay-up, curing, and vacuum bagging for repairs and fabrication. Metal fabricators focus on metals including steel, aluminum, and stainless steel, employing cutting-edge technologies such as welding, plasma cutting, and CNC machining to shape and assemble components. Both fields require precision and expertise, but composite technicians handle lightweight, corrosion-resistant materials suited for aerospace and automotive industries, while metal fabricators deal with durable, structural metals common in construction and heavy machinery.

Tools and Equipment: A Comparative Look

Composite technicians primarily rely on specialized tools like vacuum bagging systems, resin dispensers, and oven curing equipment to manipulate and cure advanced materials such as carbon fiber and fiberglass. Metal fabricators use equipment including welding machines, plasma cutters, and press brakes to shape and join various metals with precision. The choice of tools directly impacts the repair methods, as composite repairs focus on layering and curing, whereas metal fabrication centers on cutting, shaping, and welding metal components.

Industry Certifications and Training Pathways

Composite technicians often acquire certifications such as the AMT Composites Structural Specialist (CSS) and complete specialized training in advanced composite materials, curing processes, and repair techniques. Metal fabricators typically pursue certifications like AWS (American Welding Society) Welding Certification and NCCER (National Center for Construction Education and Research) credentials, focusing on metalworking, welding, and fabrication skills. Training pathways for composite technicians emphasize aerospace and automotive composite applications, while metal fabricators follow industrial-focused programs in structural metal fabrication and welding technology.

Workplace Environments and Safety Considerations

Composite technicians typically work in controlled indoor environments such as manufacturing plants or repair workshops, where exposure to dust, resins, and chemicals requires strict adherence to ventilation and protective gear protocols. Metal fabricators often operate in more varied settings, including outdoor or industrial sites, facing risks related to welding fumes, sparks, and heavy machinery, necessitating comprehensive use of fire-resistant clothing and eye protection. Both roles demand rigorous safety training tailored to their specific hazards to prevent injuries and ensure compliance with occupational health standards.

Problem-Solving and Technical Challenges

Composite technicians tackle problem-solving by working with advanced materials like carbon fiber and fiberglass, requiring expertise in layering, curing processes, and material properties to ensure structural integrity. Metal fabricators face technical challenges involving cutting, shaping, and welding metals, demanding precision and knowledge of metal behavior under stress and heat. Both roles require strong analytical skills to diagnose defects and implement effective repair strategies tailored to their respective materials.

Career Growth and Advancement Opportunities

Composite technicians benefit from specialized skills in advanced materials like carbon fiber and fiberglass, leading to growing demand in aerospace and automotive industries and higher potential for career progression into roles such as materials engineer or quality control specialist. Metal fabricators possess expertise in welding, cutting, and assembling metal structures, offering diverse opportunities across construction, manufacturing, and shipbuilding with pathways into supervisory or project management positions. Both career paths offer strong advancement potential, but composite technicians typically experience faster growth due to increasing adoption of lightweight composite materials.

Salary Expectations and Job Market Demand

Composite technicians typically earn between $45,000 and $70,000 annually, reflecting specialized skills in materials like carbon fiber and fiberglass, which are in high demand in aerospace and automotive industries. Metal fabricators have a broader salary range from $35,000 to $60,000, driven by consistent demand across construction, manufacturing, and shipbuilding sectors. The job market for composite technicians is growing faster due to advancements in lightweight material applications, while metal fabricators enjoy stable demand due to essential infrastructure projects.

Composite Technician vs Metal Fabricator Infographic

jobdiv.com

jobdiv.com