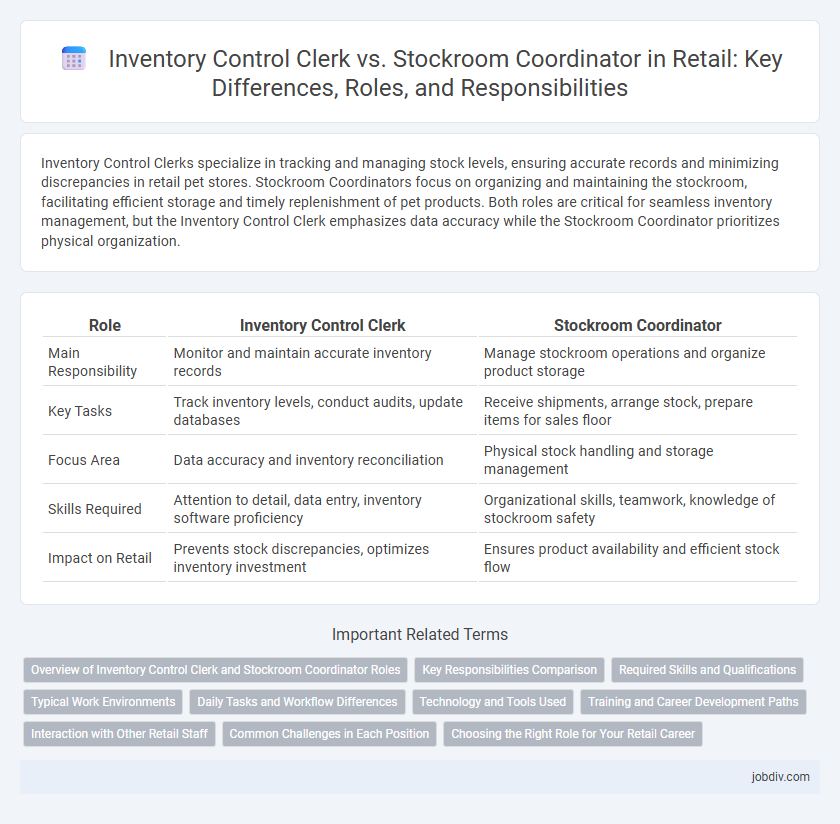

Inventory Control Clerks specialize in tracking and managing stock levels, ensuring accurate records and minimizing discrepancies in retail pet stores. Stockroom Coordinators focus on organizing and maintaining the stockroom, facilitating efficient storage and timely replenishment of pet products. Both roles are critical for seamless inventory management, but the Inventory Control Clerk emphasizes data accuracy while the Stockroom Coordinator prioritizes physical organization.

Table of Comparison

| Role | Inventory Control Clerk | Stockroom Coordinator |

|---|---|---|

| Main Responsibility | Monitor and maintain accurate inventory records | Manage stockroom operations and organize product storage |

| Key Tasks | Track inventory levels, conduct audits, update databases | Receive shipments, arrange stock, prepare items for sales floor |

| Focus Area | Data accuracy and inventory reconciliation | Physical stock handling and storage management |

| Skills Required | Attention to detail, data entry, inventory software proficiency | Organizational skills, teamwork, knowledge of stockroom safety |

| Impact on Retail | Prevents stock discrepancies, optimizes inventory investment | Ensures product availability and efficient stock flow |

Overview of Inventory Control Clerk and Stockroom Coordinator Roles

Inventory Control Clerks manage accurate tracking of inventory levels using specialized software, ensuring stock records match physical counts and preventing discrepancies. Stockroom Coordinators oversee the organization, receiving, and distribution of goods within the stockroom, optimizing storage space and facilitating timely replenishment for retail shelves. Both roles are critical in maintaining seamless supply chain operations and supporting efficient retail inventory flow.

Key Responsibilities Comparison

Inventory Control Clerks focus on monitoring stock levels, maintaining accurate records, and conducting regular audits to prevent discrepancies. Stockroom Coordinators oversee the organization and flow of inventory within the storage area, manage receiving and shipping processes, and coordinate with suppliers and sales teams to ensure timely stock availability. Both roles contribute to efficient inventory management but differ in emphasis on data accuracy versus operational logistics.

Required Skills and Qualifications

Inventory Control Clerks require strong analytical skills, proficiency in inventory management software, and attention to detail to ensure accurate stock records and minimize discrepancies. Stockroom Coordinators need excellent organizational abilities, physical stamina for managing shipments, and effective communication skills to coordinate between suppliers and retail staff. Both roles demand knowledge of supply chain processes and basic data entry competencies to maintain efficient inventory flow.

Typical Work Environments

Inventory Control Clerks typically work in warehouses, retail stores, and distribution centers where managing stock levels and auditing inventory accuracy is crucial. Stockroom Coordinators are often based in larger retail environments or supply chain hubs, overseeing the organization and flow of goods in backroom storage areas. Both roles require frequent interaction with inventory management systems and collaboration with logistics personnel to ensure efficient stock handling.

Daily Tasks and Workflow Differences

Inventory Control Clerks primarily focus on tracking inventory levels, conducting regular stock audits, and updating database records to ensure accurate stock information. Stockroom Coordinators manage the physical organization of merchandise, oversee the receipt and dispatch of goods, and coordinate with suppliers and sales teams to maintain efficient stock flow. While Inventory Control Clerks prioritize data accuracy and reporting, Stockroom Coordinators emphasize operational logistics and hands-on material handling.

Technology and Tools Used

Inventory Control Clerks utilize advanced inventory management software like ERP systems and barcode scanners to track stock levels and reconcile discrepancies efficiently. Stockroom Coordinators often employ warehouse management systems (WMS) and radio frequency identification (RFID) technology to optimize storage layout and facilitate rapid product retrieval. Both roles increasingly integrate mobile devices and real-time data analytics to enhance accuracy and streamline warehouse operations in retail environments.

Training and Career Development Paths

Inventory Control Clerks receive training focused on data management, inventory software proficiency, and audit techniques, enabling precise tracking of stock levels. Stockroom Coordinators develop skills in team supervision, workflow optimization, and logistics, preparing them for leadership roles within warehouse operations. Career advancement for Inventory Control Clerks often leads to inventory management or supply chain analyst positions, while Stockroom Coordinators typically progress towards warehouse manager or operations supervisor roles.

Interaction with Other Retail Staff

An Inventory Control Clerk collaborates closely with purchasing and sales teams to manage stock levels and ensure accurate record-keeping, facilitating smooth order processing and reducing discrepancies. A Stockroom Coordinator interacts primarily with receiving and floor staff to organize merchandise flow, streamline stocking procedures, and maintain efficient inventory distribution throughout the retail space. Both roles require effective communication with retail associates to optimize inventory accuracy and enhance overall operational efficiency.

Common Challenges in Each Position

Inventory Control Clerks often face challenges such as managing accurate record-keeping amidst frequent stock discrepancies and coordinating with multiple departments to ensure real-time inventory updates. Stockroom Coordinators struggle with optimizing storage space while handling high volumes of incoming and outgoing merchandise, which can lead to delays and misplacement of goods. Both roles require effective communication and organizational skills to prevent inventory loss and improve supply chain efficiency.

Choosing the Right Role for Your Retail Career

An Inventory Control Clerk focuses on tracking stock levels, managing inventory records, and ensuring accuracy through regular audits, which is ideal for those detail-oriented and analytical. In contrast, a Stockroom Coordinator oversees receiving shipments, organizing stockroom layout, and coordinating with sales teams to maintain efficient stock flow, suited for candidates with strong organizational and communication skills. Selecting the right role depends on your strengths in data management versus hands-on logistical coordination within retail operations.

Inventory Control Clerk vs Stockroom Coordinator Infographic

jobdiv.com

jobdiv.com