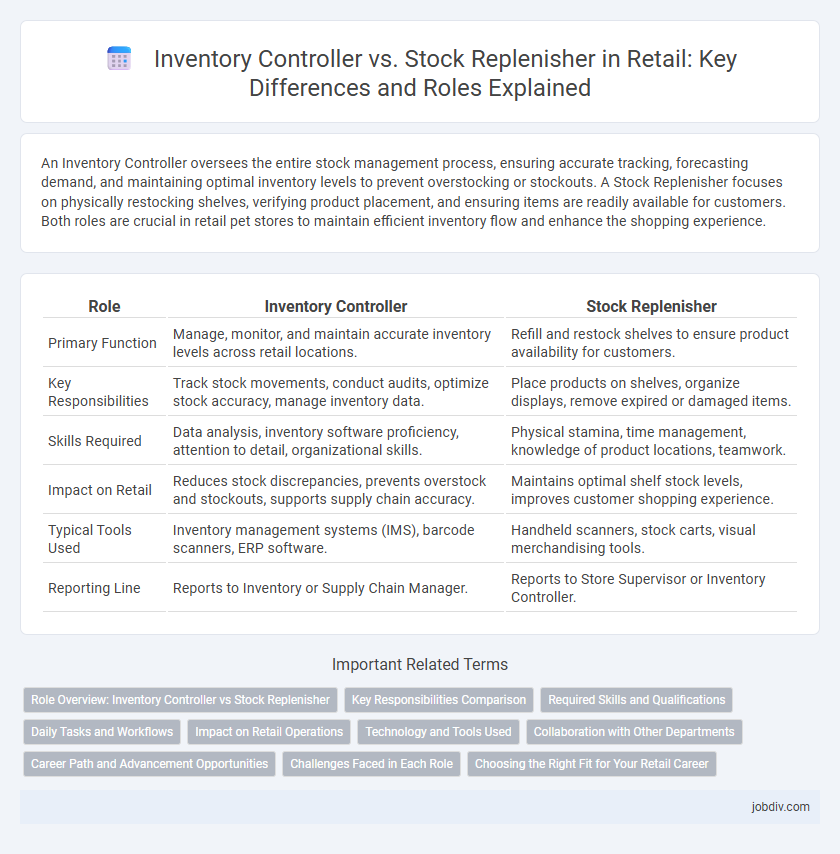

An Inventory Controller oversees the entire stock management process, ensuring accurate tracking, forecasting demand, and maintaining optimal inventory levels to prevent overstocking or stockouts. A Stock Replenisher focuses on physically restocking shelves, verifying product placement, and ensuring items are readily available for customers. Both roles are crucial in retail pet stores to maintain efficient inventory flow and enhance the shopping experience.

Table of Comparison

| Role | Inventory Controller | Stock Replenisher |

|---|---|---|

| Primary Function | Manage, monitor, and maintain accurate inventory levels across retail locations. | Refill and restock shelves to ensure product availability for customers. |

| Key Responsibilities | Track stock movements, conduct audits, optimize stock accuracy, manage inventory data. | Place products on shelves, organize displays, remove expired or damaged items. |

| Skills Required | Data analysis, inventory software proficiency, attention to detail, organizational skills. | Physical stamina, time management, knowledge of product locations, teamwork. |

| Impact on Retail | Reduces stock discrepancies, prevents overstock and stockouts, supports supply chain accuracy. | Maintains optimal shelf stock levels, improves customer shopping experience. |

| Typical Tools Used | Inventory management systems (IMS), barcode scanners, ERP software. | Handheld scanners, stock carts, visual merchandising tools. |

| Reporting Line | Reports to Inventory or Supply Chain Manager. | Reports to Store Supervisor or Inventory Controller. |

Role Overview: Inventory Controller vs Stock Replenisher

Inventory Controllers manage overall stock levels, track inventory accuracy, and coordinate with suppliers to prevent shortages or overstock situations. Stock Replenishers focus on restocking shelves, ensuring product availability for customers, and maintaining organized displays in retail environments. Both roles are crucial for seamless inventory management but differ in strategic oversight versus operational execution.

Key Responsibilities Comparison

Inventory Controllers oversee accurate tracking, auditing, and reporting of stock levels to ensure optimal inventory management and prevent stockouts or overstock situations. Stock Replenishers focus on timely restocking of shelves based on sales data and demand forecasts, maintaining product availability and minimizing empty shelf space. Both roles coordinate to balance supply chain efficiency and customer satisfaction by managing inventory flow from warehouse to sales floor.

Required Skills and Qualifications

Inventory Controllers require strong analytical skills, proficiency in inventory management software, and a deep understanding of supply chain processes to accurately track stock levels and forecast demand. Stock Replenishers need attention to detail, physical stamina, and basic knowledge of inventory procedures to efficiently restock shelves and maintain product availability. Both roles benefit from excellent organizational skills and the ability to work collaboratively within retail environments.

Daily Tasks and Workflows

Inventory Controllers analyze stock levels, forecast demand, and reconcile discrepancies to ensure accurate inventory records, enabling efficient stock management. Stock Replenishers focus on restocking shelves, monitoring product availability, and executing timely replenishment based on daily sales data and inventory reports. Their workflows intersect through continuous communication to maintain optimal stock levels, reduce out-of-stock situations, and support retail operations.

Impact on Retail Operations

An Inventory Controller ensures accurate tracking and management of stock levels, minimizing discrepancies and preventing overstock or stockouts, which directly enhances retail operational efficiency. A Stock Replenisher executes timely restocking based on inventory data, maintaining product availability and improving customer satisfaction through consistent shelf presence. Together, these roles optimize inventory flow, reduce carrying costs, and support seamless retail sales processes.

Technology and Tools Used

Inventory Controllers utilize advanced inventory management systems, barcode scanners, and AI-driven analytics platforms to monitor stock levels, forecast demand, and automate ordering processes. Stock Replenishers rely on mobile handheld devices and real-time data dashboards to efficiently restock shelves and track inventory movement throughout the store. Both roles benefit significantly from integration with ERP software and IoT-enabled sensors, enhancing accuracy and operational efficiency.

Collaboration with Other Departments

Inventory Controllers collaborate closely with purchasing and sales departments to forecast demand accurately and maintain optimal stock levels, ensuring efficient supply chain management. Stock Replenishers work primarily with warehouse and store teams to execute timely restocking based on inventory reports and sales trends, preventing stockouts and enhancing customer satisfaction. Effective communication between these roles and cross-department teams is essential to synchronize inventory flow and support retail operations.

Career Path and Advancement Opportunities

Inventory Controllers typically oversee stock accuracy, data analysis, and supply chain coordination, positioning themselves for advancement into supply chain management or procurement roles. Stock Replenishers primarily focus on restocking shelves and maintaining product availability, offering career growth into supervisory or warehouse management positions. Progressing from Stock Replenisher to Inventory Controller requires developing analytical skills and inventory management knowledge to unlock higher-level responsibilities.

Challenges Faced in Each Role

Inventory Controllers face challenges in maintaining accurate stock records, forecasting demand, and preventing overstock or stockouts, requiring strong analytical skills and attention to detail. Stock Replenishers encounter difficulties in timely restocking, managing shelf space efficiently, and ensuring product availability during peak hours, which demands swift coordination and physical endurance. Both roles must adapt to fluctuating consumer demand and supply chain disruptions to optimize retail inventory management.

Choosing the Right Fit for Your Retail Career

Inventory Controllers manage stock levels by analyzing sales data and coordinating with suppliers to prevent overstock or shortages, ensuring efficient inventory turnover. Stock Replenishers focus on physically restocking shelves and maintaining product availability for customers, emphasizing speed and accuracy in a fast-paced retail environment. Choosing between these roles depends on your preference for data-driven decision-making versus hands-on operational tasks in retail inventory management.

Inventory Controller vs Stock Replenisher Infographic

jobdiv.com

jobdiv.com