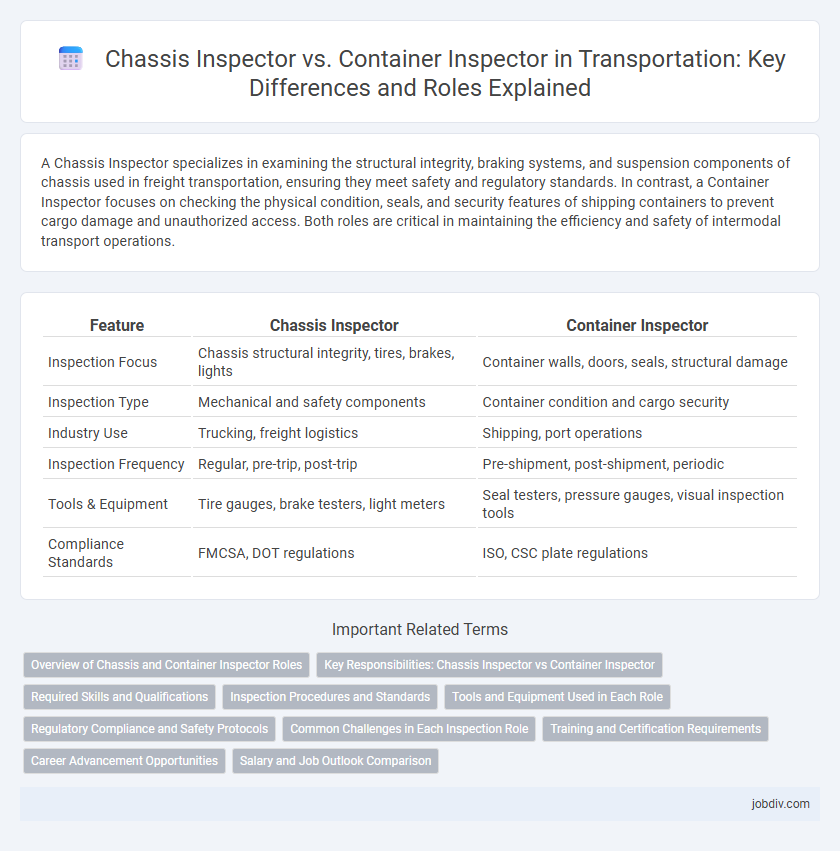

A Chassis Inspector specializes in examining the structural integrity, braking systems, and suspension components of chassis used in freight transportation, ensuring they meet safety and regulatory standards. In contrast, a Container Inspector focuses on checking the physical condition, seals, and security features of shipping containers to prevent cargo damage and unauthorized access. Both roles are critical in maintaining the efficiency and safety of intermodal transport operations.

Table of Comparison

| Feature | Chassis Inspector | Container Inspector |

|---|---|---|

| Inspection Focus | Chassis structural integrity, tires, brakes, lights | Container walls, doors, seals, structural damage |

| Inspection Type | Mechanical and safety components | Container condition and cargo security |

| Industry Use | Trucking, freight logistics | Shipping, port operations |

| Inspection Frequency | Regular, pre-trip, post-trip | Pre-shipment, post-shipment, periodic |

| Tools & Equipment | Tire gauges, brake testers, light meters | Seal testers, pressure gauges, visual inspection tools |

| Compliance Standards | FMCSA, DOT regulations | ISO, CSC plate regulations |

Overview of Chassis and Container Inspector Roles

Chassis inspectors primarily assess the structural integrity and mechanical condition of trailer chassis, ensuring safety and compliance with transportation regulations. Container inspectors focus on verifying the physical condition, seal integrity, and compliance of shipping containers to prevent cargo damage and security breaches. Both roles are critical in maintaining the efficiency and safety of intermodal freight transport operations.

Key Responsibilities: Chassis Inspector vs Container Inspector

Chassis Inspectors are responsible for examining the structural integrity, brake systems, tires, and lighting of chassis units to ensure compliance with safety regulations and operational standards. Container Inspectors focus on assessing the condition of shipping containers by inspecting doors, seals, walls, and floors for damage, leaks, and contamination risks. Both roles require detailed reporting and documentation to support maintenance schedules and regulatory compliance in transportation logistics.

Required Skills and Qualifications

Chassis Inspectors require expertise in mechanical systems, welding, and structural integrity assessment, typically holding certifications in vehicle maintenance or automotive technology. Container Inspectors must possess thorough knowledge of international shipping regulations, cargo securing methods, and hazardous materials handling, often requiring certifications in safety standards and customs compliance. Both roles demand attention to detail, strong problem-solving abilities, and experience with inspection tools and reporting software.

Inspection Procedures and Standards

Chassis inspectors follow rigorous inspection procedures focusing on structural integrity, brake systems, and tire conditions to ensure compliance with FMCSA and DOT standards. Container inspectors conduct detailed assessments of container walls, doors, and seals, adhering to ISO 6346 and CSC Plate certification requirements. Both roles require precise documentation and adherence to safety protocols to maintain transport equipment reliability and regulatory compliance.

Tools and Equipment Used in Each Role

Chassis inspectors primarily use torque wrenches, chassis gauges, and undercarriage cameras to check frame integrity, suspension components, and brake systems. Container inspectors rely on handheld scanning devices, metal thickness gauges, and moisture meters to assess container walls, floors, and seals for structural damage or contamination. Both roles utilize digital inspection software for detailed reporting and compliance verification in transportation logistics.

Regulatory Compliance and Safety Protocols

Chassis inspectors ensure regulatory compliance by verifying the structural integrity and proper maintenance of chassis frames, brakes, and lighting systems to meet Department of Transportation (DOT) standards. Container inspectors focus on safety protocols by thoroughly examining container seals, locking mechanisms, and structural damages to comply with International Maritime Organization (IMO) and Customs-Trade Partnership Against Terrorism (C-TPAT) requirements. Both roles are critical in preventing accidents, ensuring cargo security, and maintaining adherence to transportation regulations across supply chains.

Common Challenges in Each Inspection Role

Chassis Inspectors often face challenges related to detecting structural damage and wear in complex frame assemblies, requiring detailed verification of weld integrity and suspension components. Container Inspectors commonly deal with identifying corrosion, seal failures, and compliance with hazardous material regulations, demanding thorough checks of container walls and locking mechanisms. Both roles require meticulous attention to safety standards and regulatory documentation to prevent operational disruptions and ensure transportation reliability.

Training and Certification Requirements

Chassis inspectors typically require specialized training in vehicle frame integrity, brake systems, and suspension components, often supported by certification programs such as the ASE Commercial Vehicle Inspector certification. Container inspectors need comprehensive knowledge of cargo container structural standards, seal integrity, and damage assessment, with certifications from organizations like the International Cargo Handling Coordination Association (ICHCA) enhancing their qualifications. Both roles demand adherence to industry-specific safety regulations and continuous education to maintain certification validity.

Career Advancement Opportunities

Chassis Inspectors specialize in assessing the structural integrity and functionality of chassis frames, offering career advancement opportunities in equipment maintenance management and quality control supervision. Container Inspectors focus on verifying container conditions, enabling progression to roles in logistics coordination, supply chain management, and regulatory compliance. Expertise in either inspection field enhances prospects for leadership positions within transportation and freight handling industries.

Salary and Job Outlook Comparison

Chassis Inspectors typically earn an average salary ranging from $35,000 to $50,000 annually, influenced by experience and regional demand in the transportation industry. Container Inspectors command a higher average salary, often between $45,000 and $60,000 per year, reflecting specialized skills in container handling and safety compliance. Job outlook for Container Inspectors shows a stronger growth trajectory due to increasing global trade and logistics complexity, while Chassis Inspector roles remain stable with moderate demand driven by maintenance needs.

Chassis Inspector vs Container Inspector Infographic

jobdiv.com

jobdiv.com