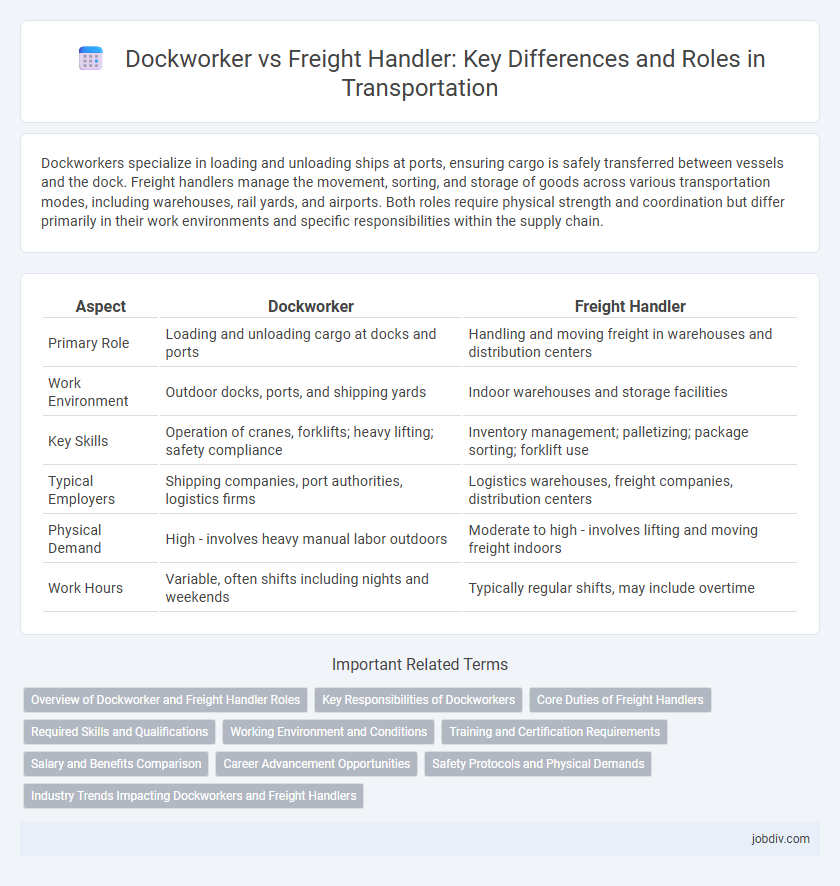

Dockworkers specialize in loading and unloading ships at ports, ensuring cargo is safely transferred between vessels and the dock. Freight handlers manage the movement, sorting, and storage of goods across various transportation modes, including warehouses, rail yards, and airports. Both roles require physical strength and coordination but differ primarily in their work environments and specific responsibilities within the supply chain.

Table of Comparison

| Aspect | Dockworker | Freight Handler |

|---|---|---|

| Primary Role | Loading and unloading cargo at docks and ports | Handling and moving freight in warehouses and distribution centers |

| Work Environment | Outdoor docks, ports, and shipping yards | Indoor warehouses and storage facilities |

| Key Skills | Operation of cranes, forklifts; heavy lifting; safety compliance | Inventory management; palletizing; package sorting; forklift use |

| Typical Employers | Shipping companies, port authorities, logistics firms | Logistics warehouses, freight companies, distribution centers |

| Physical Demand | High - involves heavy manual labor outdoors | Moderate to high - involves lifting and moving freight indoors |

| Work Hours | Variable, often shifts including nights and weekends | Typically regular shifts, may include overtime |

Overview of Dockworker and Freight Handler Roles

Dockworkers specialize in loading, unloading, and organizing cargo at shipping docks, ensuring efficient vessel turnaround and safe handling of goods. Freight handlers manage the movement, sorting, and storage of shipments within warehouses or distribution centers, focusing on package integrity and timely delivery. Both roles require physical stamina and knowledge of safety protocols but differ in work environment and specific operational tasks.

Key Responsibilities of Dockworkers

Dockworkers are primarily responsible for loading and unloading cargo from ships, ensuring safe and efficient movement of goods in maritime terminals. They operate heavy machinery such as forklifts and cranes, manage cargo storage, and adhere to safety regulations to prevent accidents. Unlike freight handlers who focus on organizing and transporting goods within warehouses or distribution centers, dockworkers specialize in securing freight on vessels and coordinating with logistics teams for timely shipments.

Core Duties of Freight Handlers

Freight handlers are responsible for loading, unloading, sorting, and moving cargo within warehouses or transportation hubs, ensuring that shipments are organized for efficient distribution. They operate equipment such as forklifts and pallet jacks to safely handle heavy or bulky freight while maintaining accurate inventory records. Unlike dockworkers who primarily work on ship docks managing cargo transfers between vessels and land transport, freight handlers focus on the internal management of goods throughout the supply chain.

Required Skills and Qualifications

Dockworkers require proficiency in operating heavy machinery such as cranes and forklifts, along with strong physical stamina and knowledge of safety protocols for loading and unloading ships. Freight handlers must possess skills in inventory management, effective communication, and the ability to handle diverse cargo types in warehouse or distribution center settings. Both roles demand attention to detail, familiarity with shipping documentation, and adherence to regulatory compliance standards.

Working Environment and Conditions

Dockworkers typically operate in outdoor shipyards and port facilities, facing exposure to varying weather conditions, heavy machinery, and loud noises. Freight handlers often work in warehouses or distribution centers with climate-controlled environments but require constant physical labor, including lifting and moving heavy packages. Both roles demand adherence to strict safety protocols to prevent accidents and injuries in physically demanding settings.

Training and Certification Requirements

Dockworkers typically require specialized training in maritime operations and certification in safety procedures such as OSHA and HAZMAT handling. Freight handlers often undergo broader logistics training with certifications like forklift operation and supply chain management, emphasizing warehouse and cargo handling skills. Both roles demand compliance with industry-specific safety standards but differ in focus areas and regulatory certifications based on their operational environments.

Salary and Benefits Comparison

Dockworkers typically earn a higher median salary, ranging from $40,000 to $65,000 annually, compared to freight handlers who average between $30,000 and $50,000. Benefits for dockworkers often include union protections, healthcare, and retirement plans, providing greater job security and compensation packages. Freight handlers may receive basic health insurance and limited retirement benefits, reflecting differences in job responsibilities and union representation.

Career Advancement Opportunities

Dockworkers often have clear career advancement opportunities through union memberships, certifications, and specialized training programs that lead to supervisory or safety compliance roles. Freight handlers can advance by gaining expertise in warehouse management systems, obtaining forklift or heavy equipment certifications, and moving into logistics coordination or inventory control positions. Both careers offer pathways to higher-paying roles in transportation management and supply chain operations, but dockworkers generally benefit from stronger collective bargaining and structured promotion tracks.

Safety Protocols and Physical Demands

Dockworkers adhere to rigorous safety protocols including the use of personal protective equipment (PPE) such as steel-toed boots, high-visibility vests, and helmets to prevent injuries while loading and unloading ships. Freight handlers follow strict guidelines that emphasize proper lifting techniques, ergonomic assessments, and equipment operation training to minimize musculoskeletal disorders and accidents in warehouse environments. Both roles require high physical stamina and strength, but dockworkers often face harsher outdoor conditions and heavier cargo, increasing the risk of slips, trips, and falls.

Industry Trends Impacting Dockworkers and Freight Handlers

Industry trends in transportation increasingly emphasize automation and digitization, transforming roles for dockworkers and freight handlers by integrating advanced robotics and AI-driven inventory management systems. The shift to e-commerce and just-in-time delivery models elevates demand for speed and accuracy in loading, unloading, and sorting tasks, while also driving skill requirements toward technical proficiency in operating automated equipment. Labor market dynamics reflect these technological advancements, with freight handlers and dockworkers needing continuous training to adapt to evolving safety protocols and workflow optimizations.

Dockworker vs Freight Handler Infographic

jobdiv.com

jobdiv.com