A waste sorter categorizes materials into recyclables, organic waste, and landfill items to streamline recycling and disposal processes. A waste processor, on the other hand, transforms sorted waste through methods like composting, incineration, or shredding to reduce volume and recover valuable resources. Efficient waste management relies on the complementary roles of both sorters and processors to minimize environmental impact and promote sustainability.

Table of Comparison

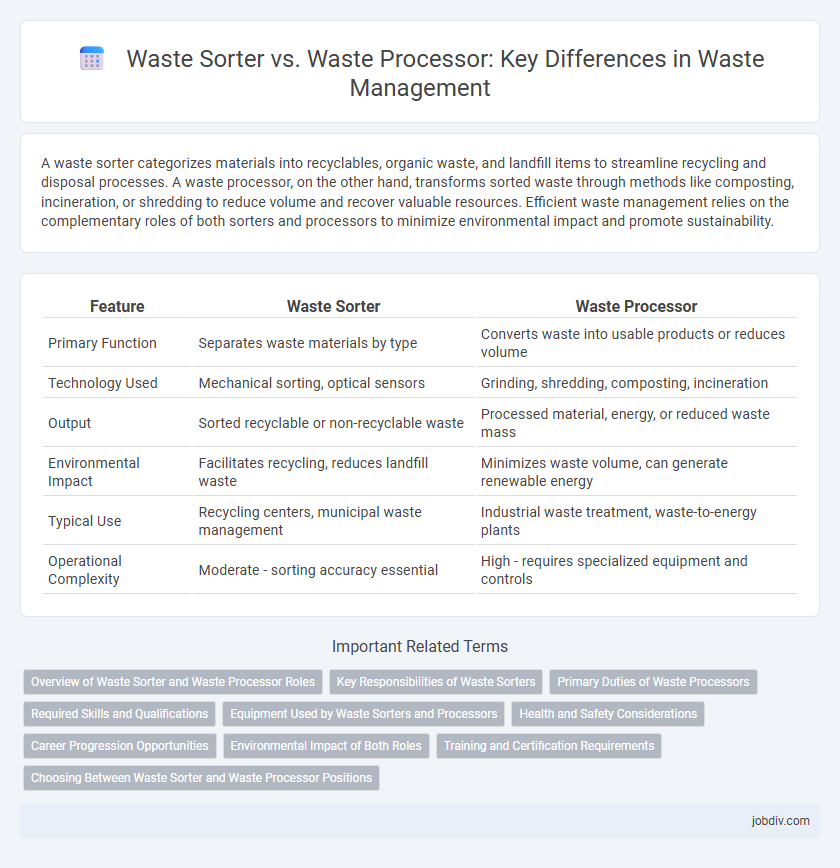

| Feature | Waste Sorter | Waste Processor |

|---|---|---|

| Primary Function | Separates waste materials by type | Converts waste into usable products or reduces volume |

| Technology Used | Mechanical sorting, optical sensors | Grinding, shredding, composting, incineration |

| Output | Sorted recyclable or non-recyclable waste | Processed material, energy, or reduced waste mass |

| Environmental Impact | Facilitates recycling, reduces landfill waste | Minimizes waste volume, can generate renewable energy |

| Typical Use | Recycling centers, municipal waste management | Industrial waste treatment, waste-to-energy plants |

| Operational Complexity | Moderate - sorting accuracy essential | High - requires specialized equipment and controls |

Overview of Waste Sorter and Waste Processor Roles

Waste sorters manually or mechanically separate recyclable and non-recyclable materials from waste streams, improving efficiency in material recovery facilities and reducing landfill volume. Waste processors handle the transformation of sorted waste into reusable products through methods like composting, shredding, or chemical treatment, enabling resource recovery and waste minimization. Both roles are essential in sustainable waste management systems, with sorters focusing on material identification and segregation, while processors focus on material conversion and reuse.

Key Responsibilities of Waste Sorters

Waste sorters are primarily responsible for manually separating recyclable materials such as plastics, metals, paper, and glass from general waste to ensure efficient recycling processes. They inspect waste streams to identify and remove contaminants, enhancing the quality and value of recovered materials. Their role is crucial in reducing landfill waste and supporting sustainable waste management systems.

Primary Duties of Waste Processors

Waste processors primarily focus on transforming waste materials through physical, chemical, or biological methods to reduce volume and toxicity, enabling safer disposal or material recovery. They operate advanced machinery and treatment systems to convert hazardous and non-hazardous waste into reusable resources or inert substances. Processing activities include composting organic waste, incineration, chemical neutralization, and recycling preparation, directly impacting environmental sustainability and regulatory compliance.

Required Skills and Qualifications

Waste sorters require strong attention to detail, physical stamina, and basic knowledge of recyclable materials to effectively separate waste types. Waste processors need technical skills in operating complex machinery, understanding of environmental regulations, and proficiency in safety protocols to transform waste into reusable resources. Both roles benefit from certifications in waste management and compliance training to ensure efficient and compliant operations.

Equipment Used by Waste Sorters and Processors

Waste sorters primarily use conveyor belts, magnetic separators, and optical sorters to separate recyclable materials based on type, size, and composition. Waste processors utilize shredders, compactors, and advanced treatment units such as anaerobic digesters or incinerators to break down, compress, or transform waste into usable energy or reduced volume. Both equipment sets are essential in the waste management chain, optimizing resource recovery and minimizing landfill dependency.

Health and Safety Considerations

Waste sorters face increased exposure to hazardous materials and sharp objects, requiring comprehensive personal protective equipment (PPE) and stringent workplace safety protocols to minimize injury and contamination risks. Waste processors, operating in controlled environments with advanced machinery, experience reduced direct contact with waste, thus lowering the risk of occupational diseases and physical harm. Implementing automated waste processing technologies enhances overall health and safety by decreasing human intervention in hazardous waste handling and improving environmental hygiene.

Career Progression Opportunities

Career progression in waste sorting often leads to supervisory roles overseeing sorting teams and quality control, while waste processing careers typically advance towards plant management and technical specialist positions. Waste processors gain expertise in recycling technologies and environmental compliance, opening pathways to engineering or sustainability consulting roles. Both fields offer growth through certifications and specialized training, but waste processing tends to provide broader opportunities in operational leadership and environmental innovation.

Environmental Impact of Both Roles

Waste sorters contribute to environmental sustainability by manually separating recyclables and hazardous materials, reducing landfill overflow and preventing pollution. Waste processors enhance this impact through advanced technologies that convert sorted waste into reusable resources or energy, minimizing greenhouse gas emissions. Together, their roles optimize waste management systems, significantly lowering the ecological footprint of discarded materials.

Training and Certification Requirements

Waste sorter roles require foundational training in material identification and safety protocols, often completed through short courses or on-the-job programs, while waste processors need more advanced certification involving hazardous material handling and compliance with environmental standards. Certified training programs for waste processors typically include OSHA regulations, waste management laws, and specialized equipment operation, reflecting their responsibility in transforming or treating waste. Effective training and certification ensure both roles maintain workplace safety and regulatory adherence, crucial for sustainable waste management operations.

Choosing Between Waste Sorter and Waste Processor Positions

Choosing between waste sorter and waste processor positions depends on the specific role within waste management operations. Waste sorters specialize in categorizing recyclable materials, enhancing the efficiency of recycling streams, while waste processors handle treating and converting waste through mechanical or chemical methods to reduce environmental impact. Candidates should evaluate their interest in manual sorting accuracy versus technical operation of waste treatment equipment when selecting the ideal position.

Waste Sorter vs Waste Processor Infographic

jobdiv.com

jobdiv.com