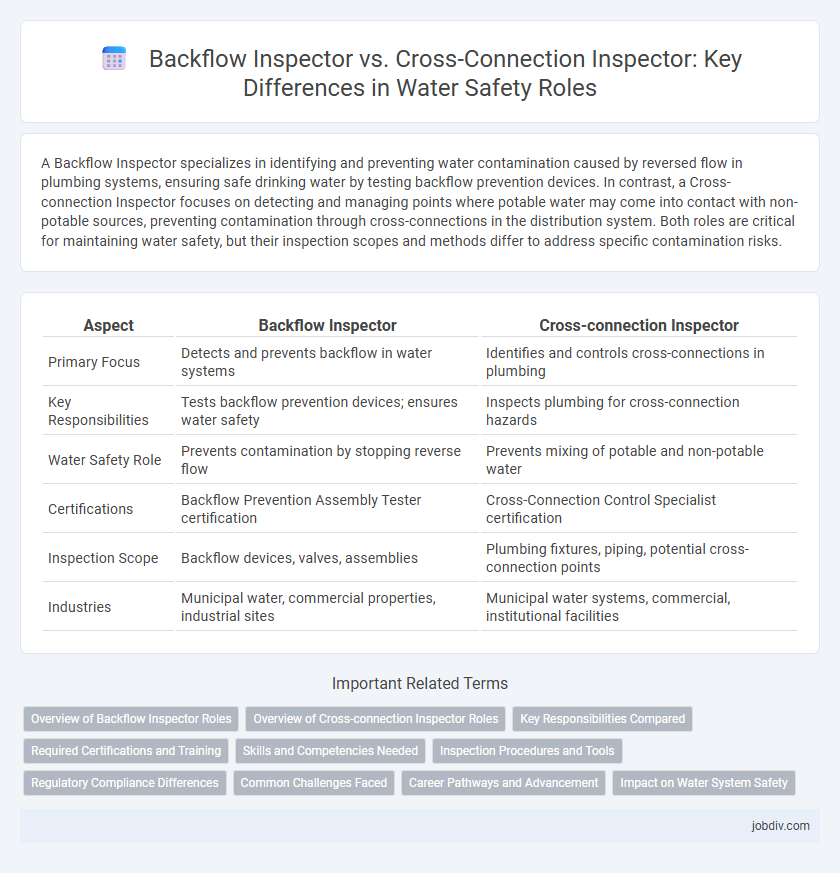

A Backflow Inspector specializes in identifying and preventing water contamination caused by reversed flow in plumbing systems, ensuring safe drinking water by testing backflow prevention devices. In contrast, a Cross-connection Inspector focuses on detecting and managing points where potable water may come into contact with non-potable sources, preventing contamination through cross-connections in the distribution system. Both roles are critical for maintaining water safety, but their inspection scopes and methods differ to address specific contamination risks.

Table of Comparison

| Aspect | Backflow Inspector | Cross-connection Inspector |

|---|---|---|

| Primary Focus | Detects and prevents backflow in water systems | Identifies and controls cross-connections in plumbing |

| Key Responsibilities | Tests backflow prevention devices; ensures water safety | Inspects plumbing for cross-connection hazards |

| Water Safety Role | Prevents contamination by stopping reverse flow | Prevents mixing of potable and non-potable water |

| Certifications | Backflow Prevention Assembly Tester certification | Cross-Connection Control Specialist certification |

| Inspection Scope | Backflow devices, valves, assemblies | Plumbing fixtures, piping, potential cross-connection points |

| Industries | Municipal water, commercial properties, industrial sites | Municipal water systems, commercial, institutional facilities |

Overview of Backflow Inspector Roles

Backflow Inspectors primarily focus on identifying and preventing the reversal of water flow that can cause contamination in potable water systems. They conduct tests on backflow prevention devices and ensure compliance with local regulations to safeguard public health. Cross-connection Inspectors assess all points where potable water may be at risk of contamination from non-potable sources, but the Backflow Inspector's role is specifically centered on maintaining the integrity of backflow prevention assemblies.

Overview of Cross-connection Inspector Roles

Cross-connection inspectors specialize in identifying and preventing potential contaminants from entering potable water systems through unintended connections, ensuring water safety and compliance with health regulations. Their role involves detailed inspections of plumbing systems to detect cross-connections, testing backflow prevention devices, and educating property owners about contamination risks. Emphasizing risk assessment and regulatory adherence, cross-connection inspectors play a critical role in maintaining water quality and public health.

Key Responsibilities Compared

Backflow Inspectors primarily focus on testing and maintaining backflow prevention devices to prevent contamination of potable water supplies, ensuring compliance with health and safety regulations. Cross-connection Inspectors identify and evaluate potential cross-connections between potable water and non-potable sources, conducting risk assessments and recommending corrective actions to eliminate contamination hazards. Both roles are essential for safeguarding water quality, but Backflow Inspectors emphasize device functionality, while Cross-connection Inspectors specialize in hazard identification and control planning.

Required Certifications and Training

Backflow Inspectors must obtain certifications such as the American Society of Sanitary Engineering (ASSE) Backflow Prevention Assembly Tester (BPAT) certification, which requires comprehensive training on backflow prevention devices and plumbing codes. Cross-connection Inspectors often need specialized training in identifying and managing cross-connection hazards, with certifications like the Certified Cross-Connection Control Specialist (CCS) offered by organizations such as the American Water Works Association (AWWA). Both roles demand ongoing education to stay current with local regulations, industry standards, and safety protocols to ensure potable water system integrity.

Skills and Competencies Needed

Backflow Inspectors require expertise in identifying and testing backflow prevention devices to ensure compliance with local water safety regulations and prevent contamination of potable water supplies. Cross-connection Inspectors must have strong analytical skills to detect and evaluate potential points where non-potable water could mix with potable water, using knowledge of plumbing systems, codes, and hazard assessment. Both roles demand thorough understanding of water quality standards, mechanical aptitude, and the ability to interpret technical diagrams and reports accurately.

Inspection Procedures and Tools

Backflow Inspectors primarily use pressure gauges and test kits to assess the integrity of backflow prevention devices, ensuring they prevent contamination in drinking water systems. Cross-connection Inspectors conduct comprehensive site surveys and utilize visual inspection tools to identify potential cross-connections between potable and non-potable water sources. Both inspectors follow strict protocols but differ in their focus; Backflow Inspectors emphasize device functionality testing, while Cross-connection Inspectors prioritize identifying and mitigating cross-connection risks.

Regulatory Compliance Differences

Backflow inspectors primarily ensure compliance with local and state regulations that prevent contaminated water from flowing back into the potable water system, focusing on testing and maintaining backflow prevention devices. Cross-connection inspectors oversee regulatory adherence by identifying and controlling any physical connections between potable and non-potable water sources, ensuring comprehensive risk management of contamination pathways. While both roles are critical for water safety, backflow inspection is often mandated by plumbing codes, whereas cross-connection inspection extends to industrial and commercial settings under broader public health regulations.

Common Challenges Faced

Backflow Inspectors and Cross-connection Inspectors often confront the challenge of accurately identifying potential contamination sources within complex plumbing systems. Both roles require thorough knowledge of local regulations and standards to ensure water safety, yet discrepancies in inspection methods can lead to inconsistent enforcement. Ensuring effective communication with property owners and resolving system compliance issues remain critical hurdles in maintaining public health through contamination prevention.

Career Pathways and Advancement

Backflow Inspectors specialize in preventing water contamination by testing and maintaining backflow prevention assemblies, often advancing to supervisory roles within municipal water departments or private water safety firms. Cross-connection Inspectors focus on identifying and controlling points where potable water and non-potable sources might mix, with career growth opportunities in regulatory agencies or environmental consulting. Both career paths require specialized certification and offer progression toward senior inspector, compliance manager, or public health advisor positions in the water safety industry.

Impact on Water System Safety

Backflow Inspectors specialize in preventing contaminants from reversing flow into the potable water supply, ensuring clean and safe drinking water. Cross-connection Inspectors identify and control points where non-potable water could mix with the public system, reducing the risk of contamination events. Both roles are critical for maintaining water system safety by minimizing health hazards associated with waterborne pollutants.

Backflow Inspector vs Cross-connection Inspector Infographic

jobdiv.com

jobdiv.com