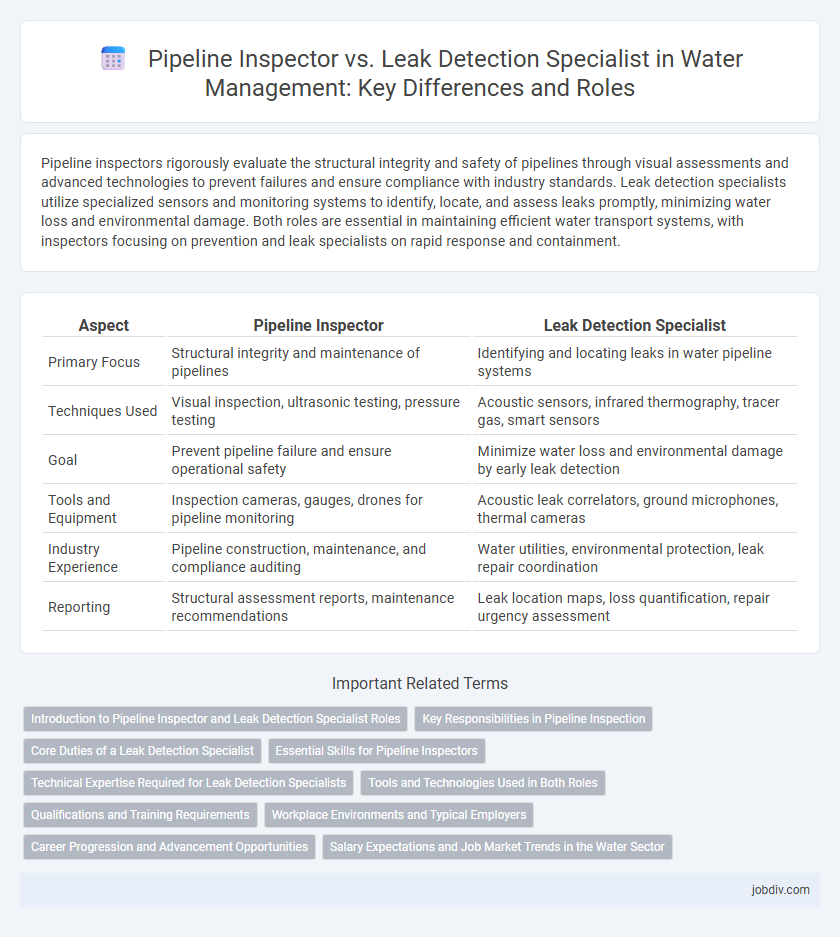

Pipeline inspectors rigorously evaluate the structural integrity and safety of pipelines through visual assessments and advanced technologies to prevent failures and ensure compliance with industry standards. Leak detection specialists utilize specialized sensors and monitoring systems to identify, locate, and assess leaks promptly, minimizing water loss and environmental damage. Both roles are essential in maintaining efficient water transport systems, with inspectors focusing on prevention and leak specialists on rapid response and containment.

Table of Comparison

| Aspect | Pipeline Inspector | Leak Detection Specialist |

|---|---|---|

| Primary Focus | Structural integrity and maintenance of pipelines | Identifying and locating leaks in water pipeline systems |

| Techniques Used | Visual inspection, ultrasonic testing, pressure testing | Acoustic sensors, infrared thermography, tracer gas, smart sensors |

| Goal | Prevent pipeline failure and ensure operational safety | Minimize water loss and environmental damage by early leak detection |

| Tools and Equipment | Inspection cameras, gauges, drones for pipeline monitoring | Acoustic leak correlators, ground microphones, thermal cameras |

| Industry Experience | Pipeline construction, maintenance, and compliance auditing | Water utilities, environmental protection, leak repair coordination |

| Reporting | Structural assessment reports, maintenance recommendations | Leak location maps, loss quantification, repair urgency assessment |

Introduction to Pipeline Inspector and Leak Detection Specialist Roles

Pipeline inspectors evaluate the structural integrity and safety of water pipelines through detailed visual inspections, pressure testing, and compliance checks to prevent failures. Leak detection specialists utilize advanced technologies such as acoustic sensors, ground-penetrating radar, and smart water meters to identify and locate leaks within water distribution systems efficiently. Both roles are critical in maintaining water infrastructure reliability, minimizing water loss, and ensuring sustainable water management practices.

Key Responsibilities in Pipeline Inspection

Pipeline inspectors perform detailed evaluations of pipelines using ultrasonic testing, radiography, and visual inspections to identify defects like corrosion, cracks, and weld integrity issues. They ensure compliance with industry standards such as ASME B31.8 and maintain accurate inspection records and reports crucial for asset management. Leak detection specialists focus primarily on pinpointing leaks using acoustic sensors, pressure monitoring, and gas detection technologies, emphasizing rapid response and containment.

Core Duties of a Leak Detection Specialist

A Leak Detection Specialist specializes in identifying, locating, and assessing water leaks within pipeline systems using advanced technologies such as acoustic sensors, infrared cameras, and ground-penetrating radar. Their core duties include conducting precise leak surveys, analyzing data to pinpoint leak sources, and recommending repair solutions to prevent water loss and environmental damage. Unlike Pipeline Inspectors who focus on structural integrity and compliance checks, Leak Detection Specialists prioritize minimizing water waste through early leak identification and efficient remediation.

Essential Skills for Pipeline Inspectors

Pipeline inspectors require a thorough understanding of pipeline construction, materials science, and regulatory compliance to ensure system integrity and safety. Proficiency in non-destructive testing methods, such as ultrasonic testing and radiography, enables accurate detection of potential flaws and corrosion. Strong analytical skills combined with the ability to interpret technical data and regulatory codes are essential for identifying risks and preventing pipeline failures.

Technical Expertise Required for Leak Detection Specialists

Leak Detection Specialists possess advanced technical expertise in acoustic sensors, ground-penetrating radar, and thermal imaging to accurately locate and diagnose pipeline leaks. Their skillset includes proficiency in data analysis software and understanding complex pipeline materials, pressures, and environmental factors affecting leak detection accuracy. This specialization ensures early leak identification, reducing environmental damage and costly pipeline repairs.

Tools and Technologies Used in Both Roles

Pipeline inspectors utilize ultrasonic testing, magnetic flux leakage, and smart pigging tools to assess pipeline integrity and detect structural defects. Leak detection specialists rely on acoustic sensors, tracer gases, infrared thermography, and advanced pressure monitoring systems to identify and pinpoint leaks in real-time. Both roles integrate geographic information systems (GIS) and data analytics platforms to enhance accuracy and streamline maintenance operations.

Qualifications and Training Requirements

Pipeline inspectors typically require certifications in pipeline integrity assessment, such as NACE or API standards, alongside training in nondestructive testing methods and regulatory compliance. Leak detection specialists often hold qualifications in sensor technology, fluid dynamics, and advanced diagnostics tools, supported by continuous training on the latest leak detection software and equipment. Both roles demand hands-on experience in pipeline systems, but leak detection specialists emphasize proficiency in real-time monitoring technologies and data analysis.

Workplace Environments and Typical Employers

Pipeline inspectors commonly work on construction sites, industrial facilities, and government projects where they assess pipeline integrity for utilities and oil companies. Leak detection specialists are typically employed by municipal water authorities, environmental agencies, and private utility firms, operating in both urban and remote areas to identify and locate water leaks. Both roles often require fieldwork, but leak detection specialists utilize advanced sensors and remote technology, while pipeline inspectors focus on physical inspections and compliance documentation.

Career Progression and Advancement Opportunities

Pipeline Inspectors typically start with entry-level roles involving visual inspections and data collection, advancing through gaining certifications in nondestructive testing and pipeline safety compliance. Leak Detection Specialists often progress by mastering advanced diagnostic technologies such as acoustic sensors and smart pigging, positioning themselves for roles in risk assessment and emergency response management. Career advancement in both fields depends on accumulating technical expertise and regulatory knowledge, with senior roles offering leadership and specialized project responsibilities.

Salary Expectations and Job Market Trends in the Water Sector

Pipeline Inspectors in the water sector typically earn between $50,000 and $75,000 annually, reflecting demand driven by infrastructure maintenance and regulatory compliance. Leak Detection Specialists command salaries ranging from $60,000 to $85,000, supported by advancements in sensor technologies and the increasing need for efficient water loss prevention. Job market trends indicate a growing emphasis on smart water management, boosting opportunities and salary prospects for professionals skilled in leak detection over traditional pipeline inspection roles.

Pipeline Inspector vs Leak Detection Specialist Infographic

jobdiv.com

jobdiv.com