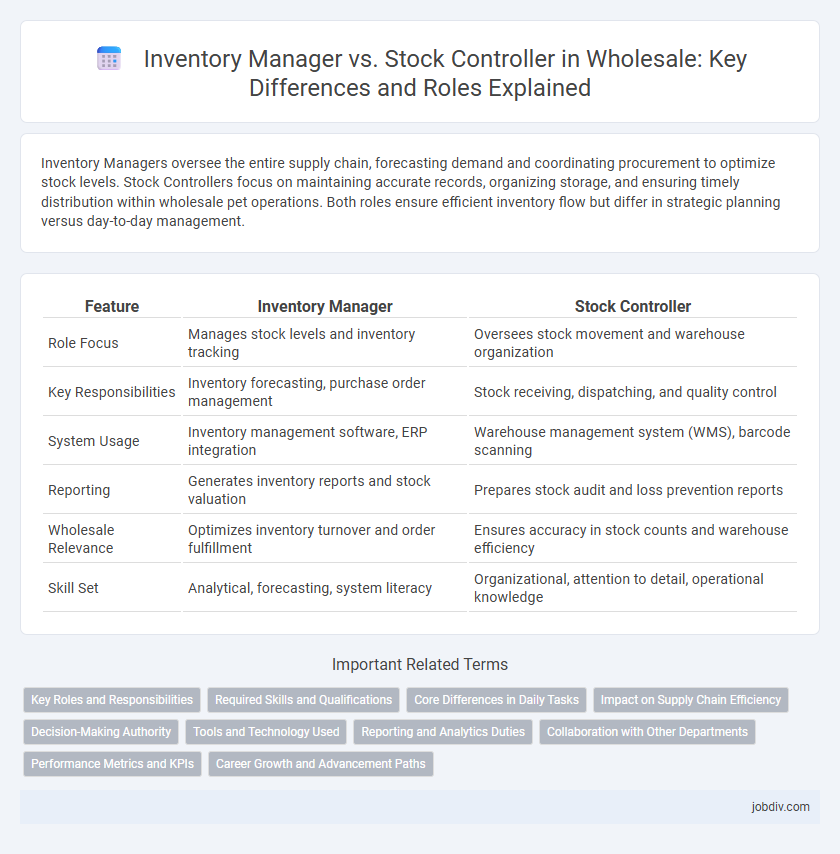

Inventory Managers oversee the entire supply chain, forecasting demand and coordinating procurement to optimize stock levels. Stock Controllers focus on maintaining accurate records, organizing storage, and ensuring timely distribution within wholesale pet operations. Both roles ensure efficient inventory flow but differ in strategic planning versus day-to-day management.

Table of Comparison

| Feature | Inventory Manager | Stock Controller |

|---|---|---|

| Role Focus | Manages stock levels and inventory tracking | Oversees stock movement and warehouse organization |

| Key Responsibilities | Inventory forecasting, purchase order management | Stock receiving, dispatching, and quality control |

| System Usage | Inventory management software, ERP integration | Warehouse management system (WMS), barcode scanning |

| Reporting | Generates inventory reports and stock valuation | Prepares stock audit and loss prevention reports |

| Wholesale Relevance | Optimizes inventory turnover and order fulfillment | Ensures accuracy in stock counts and warehouse efficiency |

| Skill Set | Analytical, forecasting, system literacy | Organizational, attention to detail, operational knowledge |

Key Roles and Responsibilities

Inventory Managers oversee the entire inventory lifecycle, including demand forecasting, procurement coordination, and stock level optimization to ensure continuous product availability. Stock Controllers focus on accurate stock recording, physical inventory audits, and discrepancy resolution to maintain data integrity and minimize stock losses. Both roles are essential in wholesale operations for efficient inventory management and supply chain accuracy.

Required Skills and Qualifications

Inventory Managers require strong analytical skills, proficiency in inventory management software, and a deep understanding of supply chain logistics to optimize stock levels and reduce costs. Stock Controllers need excellent organizational abilities, attention to detail, and experience with stocktaking procedures to maintain accurate records and prevent discrepancies. Both roles demand knowledge of demand forecasting, data analysis, and effective communication skills to coordinate with suppliers and internal teams in a wholesale environment.

Core Differences in Daily Tasks

Inventory managers oversee the overall inventory process, including forecasting demand, procurement, and tracking stock levels to ensure optimal supply. Stock controllers focus primarily on the physical management of stock, such as receiving shipments, organizing warehouse storage, and conducting regular stock audits. The core difference lies in inventory managers handling strategic planning while stock controllers manage day-to-day stock accuracy and organization.

Impact on Supply Chain Efficiency

Inventory Managers optimize stock levels using demand forecasting and real-time data analytics, minimizing overstock and stockouts to enhance supply chain efficiency. Stock Controllers focus on accurate record-keeping and ensuring proper storage conditions, reducing discrepancies and delays in order fulfillment. Together, their roles streamline inventory flow, improve order accuracy, and support timely distribution within wholesale supply chains.

Decision-Making Authority

Inventory managers hold greater decision-making authority than stock controllers, overseeing stock levels, reorder points, and supplier negotiations to optimize inventory turnover. Stock controllers primarily execute daily stock-related tasks like receiving, recording, and physical counts, with limited influence on strategic inventory decisions. This distinction impacts wholesale operations by determining who sets procurement strategies and inventory policies to balance supply and demand efficiently.

Tools and Technology Used

Inventory Managers utilize advanced ERP systems, barcode scanning technology, and AI-driven demand forecasting tools to optimize stock levels and streamline supply chain operations. Stock Controllers primarily use inventory management software, handheld scanners, and real-time tracking systems to monitor stock accuracy and manage warehouse organization. Both roles rely on integrated digital platforms, but Inventory Managers focus more on strategic analytics while Stock Controllers emphasize operational accuracy.

Reporting and Analytics Duties

Inventory Managers analyze real-time inventory data to optimize stock levels and forecast demand, utilizing advanced reporting tools and analytics platforms for strategic decision-making. Stock Controllers maintain accurate stock records through routine audits and generate detailed reports on stock movements, discrepancies, and turnover rates to ensure operational efficiency. Both roles leverage data-driven insights, but Inventory Managers focus on predictive analytics while Stock Controllers emphasize historical accuracy and compliance.

Collaboration with Other Departments

Inventory Managers coordinate closely with procurement, sales, and logistics teams to ensure optimal stock levels and timely replenishment across the supply chain. Stock Controllers work in tandem with warehouse staff and quality control departments to monitor stock accuracy, manage stock audits, and prevent discrepancies. Effective collaboration between Inventory Managers and Stock Controllers enhances overall inventory visibility, reduces stockouts, and streamlines order fulfillment processes in wholesale operations.

Performance Metrics and KPIs

Inventory Managers focus on metrics such as inventory turnover ratio, carrying cost of inventory, and order accuracy rate to optimize stock levels and reduce holding costs. Stock Controllers emphasize KPIs like stock availability rate, shrinkage percentage, and cycle count accuracy to maintain precise stock records and minimize losses. Both roles use performance data to improve supply chain efficiency but prioritize different operational aspects within wholesale environments.

Career Growth and Advancement Paths

Inventory managers in wholesale oversee procurement strategies and demand forecasting, positioning themselves for senior supply chain roles like logistics director or operations manager. Stock controllers focus on maintaining accurate stock levels and warehouse organization, often advancing to supervisory or inventory analyst positions. Career growth in inventory management typically offers broader strategic opportunities, while stock control advancements emphasize operational efficiency and accuracy.

Inventory Manager vs Stock Controller Infographic

jobdiv.com

jobdiv.com