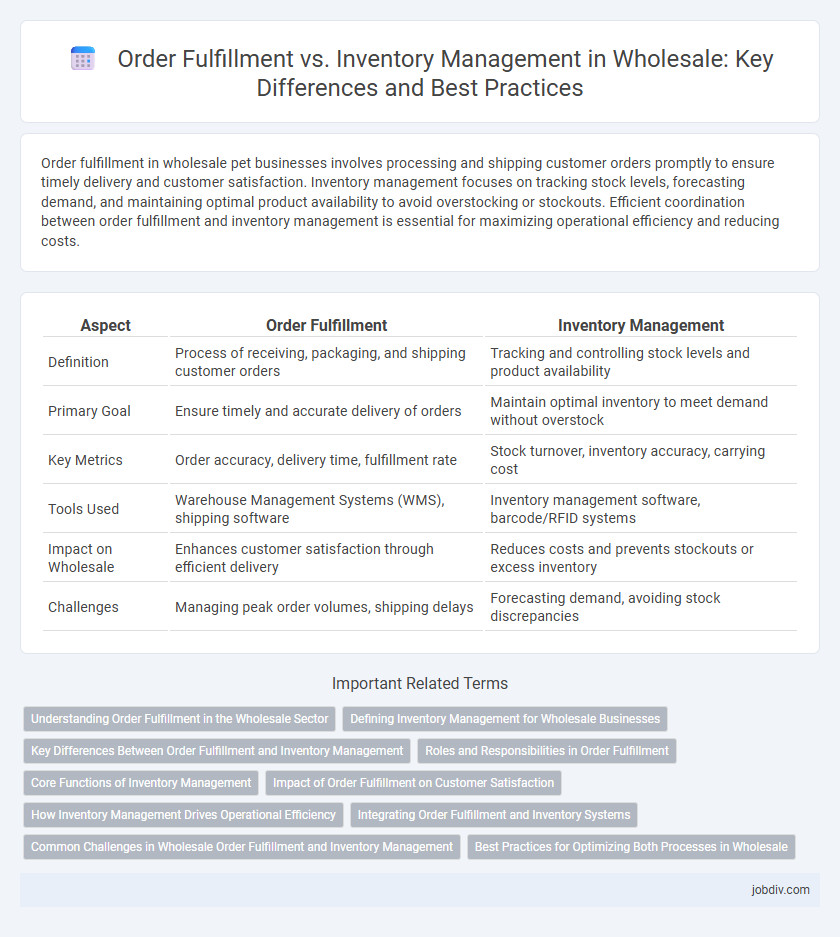

Order fulfillment in wholesale pet businesses involves processing and shipping customer orders promptly to ensure timely delivery and customer satisfaction. Inventory management focuses on tracking stock levels, forecasting demand, and maintaining optimal product availability to avoid overstocking or stockouts. Efficient coordination between order fulfillment and inventory management is essential for maximizing operational efficiency and reducing costs.

Table of Comparison

| Aspect | Order Fulfillment | Inventory Management |

|---|---|---|

| Definition | Process of receiving, packaging, and shipping customer orders | Tracking and controlling stock levels and product availability |

| Primary Goal | Ensure timely and accurate delivery of orders | Maintain optimal inventory to meet demand without overstock |

| Key Metrics | Order accuracy, delivery time, fulfillment rate | Stock turnover, inventory accuracy, carrying cost |

| Tools Used | Warehouse Management Systems (WMS), shipping software | Inventory management software, barcode/RFID systems |

| Impact on Wholesale | Enhances customer satisfaction through efficient delivery | Reduces costs and prevents stockouts or excess inventory |

| Challenges | Managing peak order volumes, shipping delays | Forecasting demand, avoiding stock discrepancies |

Understanding Order Fulfillment in the Wholesale Sector

Order fulfillment in the wholesale sector involves efficiently processing, packing, and shipping large quantities of products to retailers or distributors, ensuring timely delivery and accuracy. This process requires seamless integration with inventory management systems to track stock levels, reduce errors, and optimize warehouse operations. A robust order fulfillment strategy enhances customer satisfaction by minimizing delays and maintaining product availability throughout the supply chain.

Defining Inventory Management for Wholesale Businesses

Inventory management for wholesale businesses involves tracking stock levels, orders, sales, and deliveries to ensure optimal product availability. Efficient inventory management reduces carrying costs, prevents stockouts, and improves order accuracy, directly impacting profitability. Advanced software solutions enable wholesalers to forecast demand, automate replenishment, and streamline warehouse operations.

Key Differences Between Order Fulfillment and Inventory Management

Order fulfillment centers on processing customer orders, including picking, packing, and shipping products efficiently to ensure timely delivery. Inventory management involves monitoring stock levels, tracking product availability, and forecasting demand to prevent stockouts or overstock situations. While order fulfillment focuses on the logistics of delivering products, inventory management prioritizes maintaining optimal stock to support sales and operational efficiency.

Roles and Responsibilities in Order Fulfillment

Order fulfillment in wholesale involves precise coordination of tasks such as receiving orders, picking products, packing, and shipping to ensure timely delivery and customer satisfaction. Key responsibilities include inventory verification, quality control, and communication with logistics partners to maintain accuracy and efficiency throughout the supply chain. Effective order fulfillment directly impacts order accuracy rates, delivery speed, and overall operational costs, making it integral to wholesale business success.

Core Functions of Inventory Management

Inventory management core functions include tracking stock levels, managing replenishment processes, and ensuring accurate inventory records in a wholesale environment. Effective inventory control minimizes stockouts and overstocks, improving order fulfillment speed and customer satisfaction. Integration of real-time inventory data with order processing systems enhances operational efficiency and reduces fulfillment errors.

Impact of Order Fulfillment on Customer Satisfaction

Efficient order fulfillment directly enhances customer satisfaction by ensuring timely and accurate delivery of products, minimizing errors and delays that can lead to dissatisfaction. Streamlined processes in picking, packing, and shipping improve order accuracy and speed, which positively impacts repeat purchase rates and brand loyalty in wholesale operations. High order fulfillment performance reduces customer complaints and returns, thereby strengthening overall client trust and retention.

How Inventory Management Drives Operational Efficiency

Effective inventory management optimizes stock levels, reduces holding costs, and prevents stockouts, directly enhancing order fulfillment speed and accuracy. Automated tracking systems enable real-time visibility into inventory, allowing wholesalers to quickly adjust to demand fluctuations and streamline warehouse operations. Improved inventory turnover and data-driven decision-making minimize delays and errors, driving overall operational efficiency in the wholesale supply chain.

Integrating Order Fulfillment and Inventory Systems

Integrating order fulfillment and inventory systems enhances accuracy by providing real-time stock visibility, reducing errors, and preventing stockouts or overstock situations. Seamless integration streamlines processes, accelerates order processing, and improves customer satisfaction through timely deliveries. Advanced wholesale platforms leverage APIs and automation tools to synchronize inventory updates with order fulfillment workflows, optimizing supply chain efficiency.

Common Challenges in Wholesale Order Fulfillment and Inventory Management

Common challenges in wholesale order fulfillment and inventory management include maintaining accurate stock levels to prevent overstocking or stockouts, which directly impact customer satisfaction and cash flow. Coordinating timely order processing and shipping while managing returns and damaged goods requires efficient communication across multiple departments and reliable technology systems. Balancing demand forecasting accuracy with supplier lead times and warehouse capacity remains critical to optimizing inventory turnover and reducing carrying costs.

Best Practices for Optimizing Both Processes in Wholesale

Efficient order fulfillment and inventory management are critical for wholesale success, requiring real-time inventory tracking and automated replenishment systems to prevent stockouts and overstock. Integrating advanced warehouse management software with predictive analytics enhances accuracy in demand forecasting and streamlines order processing. Prioritizing seamless communication between sales, warehouse, and logistics teams ensures timely deliveries and improved customer satisfaction.

Order Fulfillment vs Inventory Management Infographic

jobdiv.com

jobdiv.com