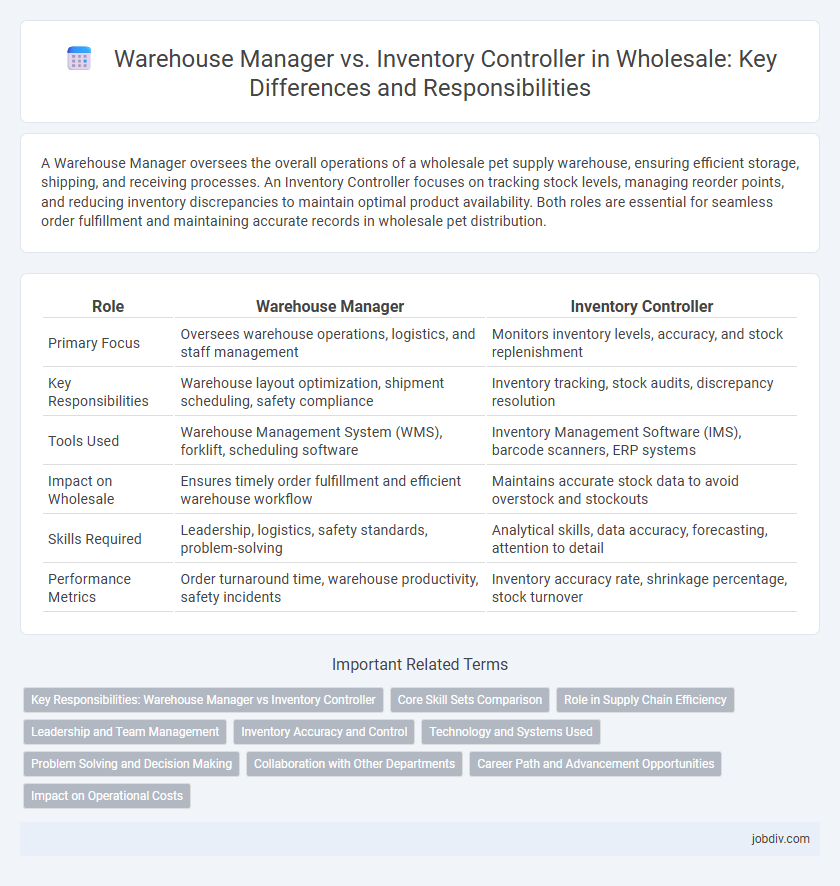

A Warehouse Manager oversees the overall operations of a wholesale pet supply warehouse, ensuring efficient storage, shipping, and receiving processes. An Inventory Controller focuses on tracking stock levels, managing reorder points, and reducing inventory discrepancies to maintain optimal product availability. Both roles are essential for seamless order fulfillment and maintaining accurate records in wholesale pet distribution.

Table of Comparison

| Role | Warehouse Manager | Inventory Controller |

|---|---|---|

| Primary Focus | Oversees warehouse operations, logistics, and staff management | Monitors inventory levels, accuracy, and stock replenishment |

| Key Responsibilities | Warehouse layout optimization, shipment scheduling, safety compliance | Inventory tracking, stock audits, discrepancy resolution |

| Tools Used | Warehouse Management System (WMS), forklift, scheduling software | Inventory Management Software (IMS), barcode scanners, ERP systems |

| Impact on Wholesale | Ensures timely order fulfillment and efficient warehouse workflow | Maintains accurate stock data to avoid overstock and stockouts |

| Skills Required | Leadership, logistics, safety standards, problem-solving | Analytical skills, data accuracy, forecasting, attention to detail |

| Performance Metrics | Order turnaround time, warehouse productivity, safety incidents | Inventory accuracy rate, shrinkage percentage, stock turnover |

Key Responsibilities: Warehouse Manager vs Inventory Controller

Warehouse Managers oversee overall warehouse operations, including staff supervision, shipment coordination, and maintaining safety standards to ensure efficient storage and distribution processes. Inventory Controllers focus on monitoring stock levels, managing inventory records, and conducting regular audits to prevent discrepancies and optimize stock accuracy. Both roles collaborate to streamline supply chain efficiency and minimize operational costs in wholesale environments.

Core Skill Sets Comparison

Warehouse Managers excel in leadership, logistics coordination, and space optimization, ensuring efficient movement and storage of goods within wholesale operations. Inventory Controllers specialize in stock accuracy, demand forecasting, and data analysis to maintain optimal inventory levels and minimize shrinkage. Both roles require strong organizational skills, but Warehouse Managers emphasize operational management while Inventory Controllers focus on inventory accuracy and financial control.

Role in Supply Chain Efficiency

Warehouse Managers oversee storage operations, ensuring optimal space utilization and timely dispatch of goods, directly impacting supply chain efficiency by minimizing delays. Inventory Controllers monitor stock levels and coordinate replenishments to prevent stockouts or overstock situations, maintaining a balanced inventory flow. Their combined efforts streamline order fulfillment and reduce operational costs, enhancing overall wholesale supply chain performance.

Leadership and Team Management

Warehouse Managers lead warehouse operations by coordinating teams to ensure efficient storage, order fulfillment, and shipping processes, emphasizing strategic planning and resource allocation. Inventory Controllers focus on supervising stock levels, conducting audits, and implementing inventory control systems, prioritizing accuracy and minimizing discrepancies through team oversight. Both roles require strong leadership skills, but Warehouse Managers typically oversee larger teams and broader operational workflows, while Inventory Controllers specialize in managing team efforts related to precision and stock optimization.

Inventory Accuracy and Control

A Warehouse Manager oversees overall warehousing operations focusing on efficient storage and distribution, while an Inventory Controller specializes in monitoring stock levels to ensure inventory accuracy and prevent discrepancies. Inventory Controllers implement precise tracking systems, conduct regular audits, and manage reorder points to maintain optimal stock control. Accurate inventory management reduces stockouts and overstock situations, directly impacting wholesale supply chain efficiency and profitability.

Technology and Systems Used

Warehouse Managers utilize advanced warehouse management systems (WMS) like SAP EWM and Oracle WMS Cloud to optimize storage, picking, and shipping processes, ensuring efficient operations. Inventory Controllers rely heavily on inventory management software such as NetSuite and Fishbowl Inventory, integrating barcode scanning and RFID technology to maintain accurate stock levels and prevent discrepancies. Both roles leverage real-time data analytics and automation tools to enhance supply chain visibility and streamline wholesale distribution workflows.

Problem Solving and Decision Making

Warehouse Managers excel in problem solving by overseeing logistics challenges, optimizing storage solutions, and ensuring smooth workflow operations in wholesale distribution centers. Inventory Controllers focus on decision making through data analysis, forecasting demand, and adjusting stock levels to prevent shortages or overstock situations. Both roles collaborate to enhance operational efficiency, with Warehouse Managers addressing physical process issues and Inventory Controllers managing inventory accuracy and cost control.

Collaboration with Other Departments

Warehouse Managers coordinate with sales, logistics, and procurement teams to streamline order fulfillment and optimize storage solutions. Inventory Controllers work closely with finance and supply chain departments to ensure accurate stock levels and minimize carrying costs. Both roles require effective cross-departmental communication to enhance overall operational efficiency in wholesale distribution.

Career Path and Advancement Opportunities

Warehouse Managers typically oversee the entire warehouse operation, coordinating logistics, staff, and inventory flow, positioning them for higher roles in supply chain management or operations director roles. Inventory Controllers specialize in managing stock accuracy, data analysis, and supply forecasting, which can lead to careers in procurement, demand planning, or inventory strategy roles. Advancement opportunities for Warehouse Managers often involve broader leadership and operational responsibilities, while Inventory Controllers progress through data-driven analytical roles focused on optimizing inventory levels and reducing costs.

Impact on Operational Costs

A Warehouse Manager directly influences operational costs by optimizing space utilization, streamlining workflow, and reducing labor expenses through efficient team management. An Inventory Controller impacts costs by minimizing stock discrepancies, preventing overstocking or stockouts, and ensuring accurate demand forecasting, which reduces holding and shortage costs. Both roles are vital for controlling overheads but differ in focus: warehouse management targets physical execution while inventory control emphasizes stock accuracy and cost efficiency.

Warehouse Manager vs Inventory Controller Infographic

jobdiv.com

jobdiv.com