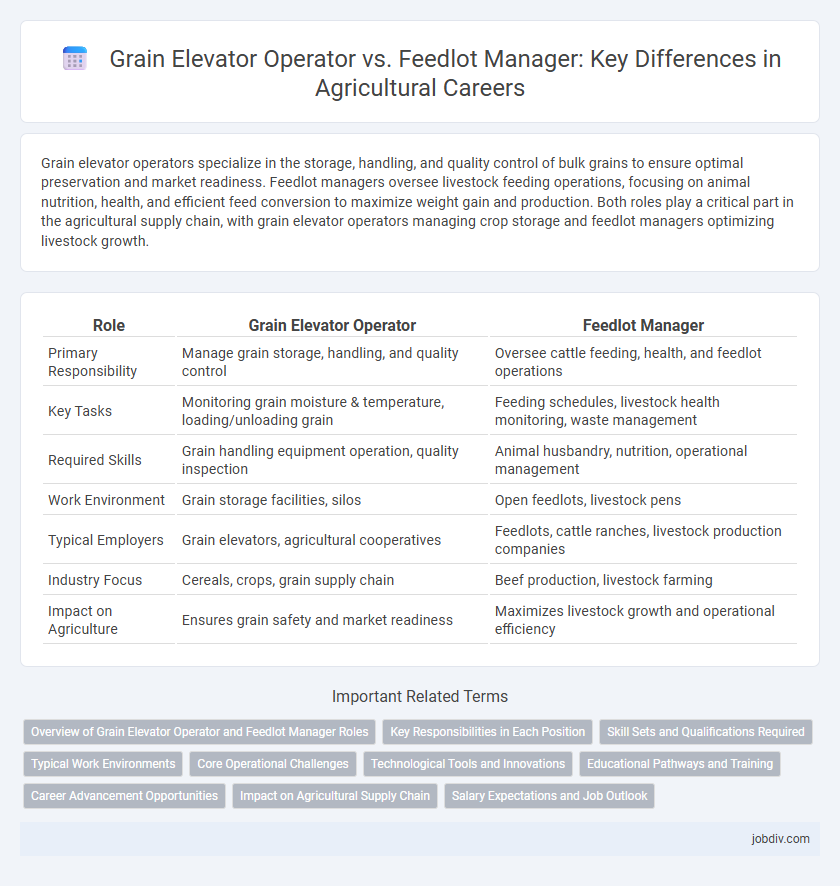

Grain elevator operators specialize in the storage, handling, and quality control of bulk grains to ensure optimal preservation and market readiness. Feedlot managers oversee livestock feeding operations, focusing on animal nutrition, health, and efficient feed conversion to maximize weight gain and production. Both roles play a critical part in the agricultural supply chain, with grain elevator operators managing crop storage and feedlot managers optimizing livestock growth.

Table of Comparison

| Role | Grain Elevator Operator | Feedlot Manager |

|---|---|---|

| Primary Responsibility | Manage grain storage, handling, and quality control | Oversee cattle feeding, health, and feedlot operations |

| Key Tasks | Monitoring grain moisture & temperature, loading/unloading grain | Feeding schedules, livestock health monitoring, waste management |

| Required Skills | Grain handling equipment operation, quality inspection | Animal husbandry, nutrition, operational management |

| Work Environment | Grain storage facilities, silos | Open feedlots, livestock pens |

| Typical Employers | Grain elevators, agricultural cooperatives | Feedlots, cattle ranches, livestock production companies |

| Industry Focus | Cereals, crops, grain supply chain | Beef production, livestock farming |

| Impact on Agriculture | Ensures grain safety and market readiness | Maximizes livestock growth and operational efficiency |

Overview of Grain Elevator Operator and Feedlot Manager Roles

Grain elevator operators manage the receipt, storage, and shipment of bulk grains, ensuring quality control and inventory accuracy in grain handling facilities. Feedlot managers oversee the daily operations of livestock feedlots, including animal health, feeding programs, and facility maintenance to optimize cattle growth and production. Both roles are critical in the agricultural supply chain, focusing respectively on crop storage logistics and livestock production management.

Key Responsibilities in Each Position

Grain elevator operators oversee the intake, storage, and quality control of various grains such as corn, wheat, and soybeans, ensuring proper handling to prevent spoilage and contamination. Feedlot managers are responsible for managing large-scale livestock feeding operations, focusing on animal health, nutrition, feed efficiency, and operational logistics to maximize growth and production. Both roles require expertise in inventory management and compliance with safety and environmental regulations within the agricultural supply chain.

Skill Sets and Qualifications Required

Grain Elevator Operators require expertise in grain handling systems, inventory management, and safety protocols, with a strong foundation in agronomy and machinery operation. Feedlot Managers need skills in animal husbandry, nutrition planning, and environmental compliance, along with knowledge of livestock health and feed efficiency. Both roles demand problem-solving abilities and experience with agricultural regulations but differ in their focus on crop storage versus livestock production.

Typical Work Environments

Grain elevator operators typically work in large storage facilities where they manage the intake, storage, and shipment of grain, often in controlled indoor environments with heavy machinery. Feedlot managers operate primarily outdoors on livestock feeding operations, overseeing cattle or other animals within expansive pens that require constant monitoring and maintenance. Both roles demand strong attention to safety protocols and efficient workflow, but their environments differ significantly between grain storage and animal husbandry settings.

Core Operational Challenges

Grain elevator operators face core operational challenges such as managing large-scale grain storage, maintaining quality control to prevent spoilage, and coordinating complex logistics for timely grain shipment. Feedlot managers focus on optimizing animal health, balancing nutrient requirements, and mitigating environmental impacts like waste management and odor control. Both roles require precise monitoring and efficient resource allocation to sustain productivity and comply with regulatory standards in agriculture.

Technological Tools and Innovations

Grain elevator operators leverage advanced grain monitoring systems, automated conveyor belts, and moisture control technologies to ensure optimal storage conditions and minimize grain loss. Feedlot managers implement precision livestock farming tools, including automated feeding systems, real-time health monitoring sensors, and data analytics platforms to enhance animal welfare and feed efficiency. Both roles rely heavily on integrated software solutions for inventory management, operational forecasting, and regulatory compliance in modern agricultural practices.

Educational Pathways and Training

Grain elevator operators typically pursue vocational training or certifications in agricultural technology, grain science, or logistics, often gaining hands-on experience through apprenticeships or entry-level positions. Feedlot managers usually require a more advanced education, such as a bachelor's degree in animal science, agriculture, or agribusiness, alongside practical training in livestock management and nutrition. Both roles prioritize industry-specific knowledge, but feedlot managers undergo more comprehensive studies to oversee large-scale animal feeding operations effectively.

Career Advancement Opportunities

Grain elevator operators can advance their careers by gaining expertise in logistics management, safety compliance, and grain quality control, potentially moving into supervisory or regional manager roles within agribusiness companies. Feedlot managers enhance career prospects by developing skills in animal nutrition, herd health management, and operational efficiency, leading to opportunities in large-scale livestock production management or agricultural consulting. Both roles benefit from continuous education and industry certifications, which are critical for ascending to executive positions in the agriculture sector.

Impact on Agricultural Supply Chain

Grain elevator operators ensure efficient storage and handling of harvested crops, directly influencing grain availability and quality for processing and distribution. Feedlot managers oversee livestock feeding operations, optimizing animal growth and feed efficiency, which impacts meat production volume and timing. Both roles are critical for maintaining a balanced agricultural supply chain, with operators managing crop flow and managers controlling feedlot outputs that meet market demand.

Salary Expectations and Job Outlook

Grain elevator operators typically earn an average salary ranging from $35,000 to $50,000 annually, with job growth projected to remain steady due to consistent demand in grain storage and distribution. Feedlot managers often command higher salaries, averaging between $50,000 and $75,000 per year, driven by expertise in livestock nutrition and feed management, with employment opportunities expanding in regions focused on beef production. Both roles require specific agricultural knowledge but face differing market dynamics impacting salary expectations and job outlook.

Grain Elevator Operator vs Feedlot Manager Infographic

jobdiv.com

jobdiv.com