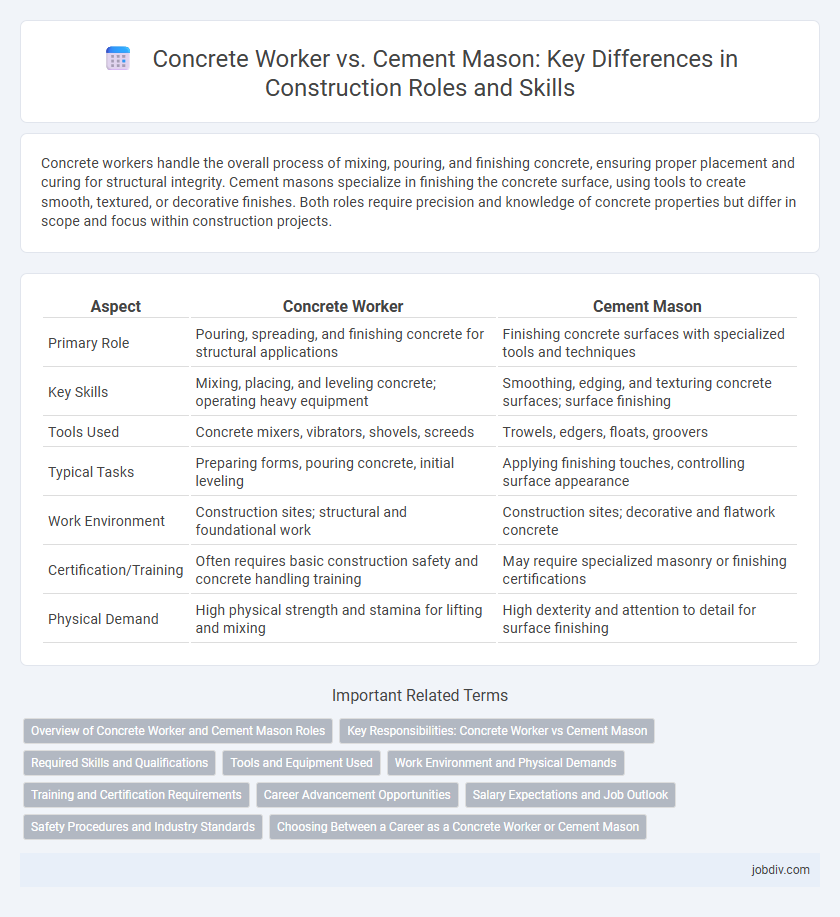

Concrete workers handle the overall process of mixing, pouring, and finishing concrete, ensuring proper placement and curing for structural integrity. Cement masons specialize in finishing the concrete surface, using tools to create smooth, textured, or decorative finishes. Both roles require precision and knowledge of concrete properties but differ in scope and focus within construction projects.

Table of Comparison

| Aspect | Concrete Worker | Cement Mason |

|---|---|---|

| Primary Role | Pouring, spreading, and finishing concrete for structural applications | Finishing concrete surfaces with specialized tools and techniques |

| Key Skills | Mixing, placing, and leveling concrete; operating heavy equipment | Smoothing, edging, and texturing concrete surfaces; surface finishing |

| Tools Used | Concrete mixers, vibrators, shovels, screeds | Trowels, edgers, floats, groovers |

| Typical Tasks | Preparing forms, pouring concrete, initial leveling | Applying finishing touches, controlling surface appearance |

| Work Environment | Construction sites; structural and foundational work | Construction sites; decorative and flatwork concrete |

| Certification/Training | Often requires basic construction safety and concrete handling training | May require specialized masonry or finishing certifications |

| Physical Demand | High physical strength and stamina for lifting and mixing | High dexterity and attention to detail for surface finishing |

Overview of Concrete Worker and Cement Mason Roles

Concrete workers shape, place, and finish concrete for various construction projects, ensuring structural integrity and surface quality. Cement masons specialize in smoothing, leveling, and texturing concrete surfaces, often finishing floors, sidewalks, and driveways with precision techniques. Both roles require expertise in handling concrete materials but differ in focus, with concrete workers managing broader preparation and placement tasks while cement masons concentrate on surface detailing and finishing.

Key Responsibilities: Concrete Worker vs Cement Mason

Concrete workers focus on placing, leveling, and finishing concrete for sidewalks, roads, and foundations, ensuring proper curing and mixing on-site. Cement masons specialize in applying, smoothing, and shaping finished concrete surfaces, often using tools like trowels and floats to achieve detailed texture and patterns. Both roles require knowledge of concrete properties but differ as concrete workers handle bulk material management while cement masons focus on surface quality and aesthetics.

Required Skills and Qualifications

Concrete workers require proficiency in mixing, pouring, and leveling concrete with strong physical stamina and attention to detail for structural integrity. Cement masons specialize in finishing surfaces, demanding skills in smoothing, sealing, and decorative techniques, combined with knowledge of curing processes. Both roles typically need a high school diploma or equivalent, on-the-job training, and familiarity with safety standards and construction site protocols.

Tools and Equipment Used

Concrete workers primarily use tools such as concrete mixers, vibrators, and screeds to pour, spread, and level concrete. Cement masons focus on finishing tools like trowels, floats, edgers, and groovers to smooth and shape the surface of the concrete. Both roles rely on equipment like bull floats, hand floats, and power trowels to ensure structural integrity and aesthetic quality in construction projects.

Work Environment and Physical Demands

Concrete workers and cement masons often work outdoors on construction sites, frequently exposed to varying weather conditions and noise hazards. Both roles require significant physical strength and stamina, involving heavy lifting, bending, and prolonged standing on uneven surfaces. Concrete workers typically handle the mixing and pouring of concrete, while cement masons specialize in smoothing and finishing surfaces, demanding precise hand-eye coordination and endurance.

Training and Certification Requirements

Concrete workers typically undergo on-the-job training, learning skills such as mixing, pouring, and finishing concrete, with certification often optional but available through organizations like the American Concrete Institute (ACI). Cement masons require more specialized training focusing on finishing techniques, surface treatments, and decorative concrete, often earning certifications in flatwork, concrete finishing, or decorative concrete through ACI or the Associated General Contractors (AGC). Both roles benefit from OSHA safety training and local licensing requirements, ensuring proper handling of materials and adherence to construction standards.

Career Advancement Opportunities

Concrete workers specialize in pouring and setting concrete for foundational structures, with career advancement often leading to site supervisory roles or specialized trade certifications. Cement masons focus on finishing and smoothing concrete surfaces, offering opportunities to progress into project management or expert craftsmanship positions such as decorative concrete specialist. Both careers benefit from acquiring skills in equipment operation, blueprint reading, and safety compliance to enhance promotion prospects within the construction industry.

Salary Expectations and Job Outlook

Concrete workers earn an average salary of $40,000 to $55,000 annually, reflecting steady demand in residential and commercial construction projects, with a projected job growth rate of 8% through 2031. Cement masons, skilled in finishing concrete surfaces, typically command higher wages ranging from $45,000 to $65,000 per year due to specialized expertise, with job opportunities expected to grow by 10% as infrastructure development continues. Both professions require physical endurance and precision, but cement masons benefit from increased salary potential and faster employment growth driven by urbanization and large-scale public works.

Safety Procedures and Industry Standards

Concrete workers and cement masons adhere to strict safety procedures and industry standards to minimize hazards such as exposure to silica dust, chemical burns, and heavy machinery accidents. Concrete workers primarily focus on mixing, pouring, and curing concrete while using protective gear like respiratory masks and gloves to ensure onsite safety. Cement masons specialize in finishing and shaping concrete surfaces, following OSHA regulations and employing ergonomic tools to prevent musculoskeletal injuries during troweling and smoothing tasks.

Choosing Between a Career as a Concrete Worker or Cement Mason

Concrete workers specialize in mixing, pouring, and finishing concrete for foundations, roads, and large-scale structures, requiring strength and precision. Cement masons focus on the detailed finishing of concrete surfaces, including smoothing, leveling, and applying textures, demanding craftsmanship and attention to detail. Choosing between these careers depends on preference for hands-on structural work versus specialized finish work and long-term skill development in concrete artistry.

Concrete Worker vs Cement Mason Infographic

jobdiv.com

jobdiv.com