Plumbers specialize in installing and repairing water supply and drainage systems in residential and commercial buildings, emphasizing sanitation and water flow. Pipefitters focus on assembling and maintaining high-pressure piping systems used in industrial settings such as factories and power plants, handling gas, steam, and chemical transport. Both trades require precision and knowledge of materials but differ primarily in application environments and system complexity.

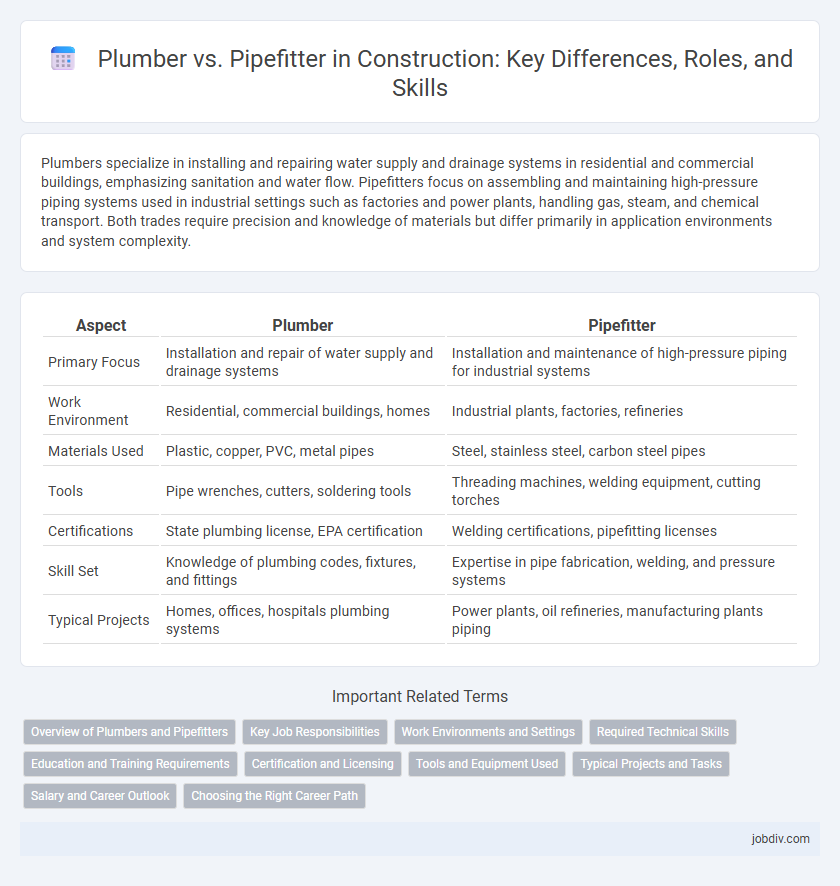

Table of Comparison

| Aspect | Plumber | Pipefitter |

|---|---|---|

| Primary Focus | Installation and repair of water supply and drainage systems | Installation and maintenance of high-pressure piping for industrial systems |

| Work Environment | Residential, commercial buildings, homes | Industrial plants, factories, refineries |

| Materials Used | Plastic, copper, PVC, metal pipes | Steel, stainless steel, carbon steel pipes |

| Tools | Pipe wrenches, cutters, soldering tools | Threading machines, welding equipment, cutting torches |

| Certifications | State plumbing license, EPA certification | Welding certifications, pipefitting licenses |

| Skill Set | Knowledge of plumbing codes, fixtures, and fittings | Expertise in pipe fabrication, welding, and pressure systems |

| Typical Projects | Homes, offices, hospitals plumbing systems | Power plants, oil refineries, manufacturing plants piping |

Overview of Plumbers and Pipefitters

Plumbers specialize in installing and repairing water, drainage, and sanitary systems in residential, commercial, and industrial settings, focusing on water supply and waste removal. Pipefitters primarily work with high-pressure piping systems used for gas, steam, and chemicals, often in industrial facilities like factories and power plants. Both trades require knowledge of pipe materials and blueprints but differ in the pressure and type of systems they manage.

Key Job Responsibilities

Plumbers specialize in installing and repairing water supply and drainage systems, ensuring proper flow and leak prevention in residential and commercial structures. Pipefitters focus on assembling, installing, and maintaining piping systems used for transporting chemicals, gases, and high-pressure liquids in industrial settings. Both roles require knowledge of blueprints and safety standards, but plumbers primarily handle plumbing fixtures while pipefitters work with complex piping systems and welding techniques.

Work Environments and Settings

Plumbers typically work in residential, commercial, and industrial settings, handling water supply and drainage systems in new constructions and renovations. Pipefitters primarily operate in industrial environments such as power plants, factories, and chemical plants, installing and maintaining high-pressure piping systems. Both professionals often collaborate on large-scale projects but differ significantly in the materials and systems they specialize in.

Required Technical Skills

Plumbers require expertise in installing, repairing, and maintaining water supply and drainage systems, utilizing skills in pipe cutting, joining techniques, and blueprint reading. Pipefitters specialize in assembling and maintaining high-pressure piping systems, demanding proficiency in welding, bending, and system layout interpretation. Both trades need knowledge of safety regulations, material types, and use of specialized tools for accurate installation and maintenance in residential, commercial, or industrial settings.

Education and Training Requirements

Plumbers typically complete an apprenticeship program lasting 4 to 5 years, combining paid on-the-job training with classroom instruction in areas like pipe systems, safety protocols, and blueprint reading. Pipefitters also undergo rigorous apprenticeships, often 4 to 5 years, emphasizing installation and maintenance of piping systems that handle high-pressure liquids and gases, with specialized training in welding and blueprint interpretation. Both require a high school diploma or equivalent for entry, but pipefitters may pursue additional certifications in welding and heavy equipment operation to advance in their careers.

Certification and Licensing

Plumbers typically require state or local licensing, which involves passing exams on plumbing codes, safety regulations, and system design to ensure compliance and safety. Pipefitters often need specialized certifications such as those from the National Center for Construction Education and Research (NCCER) or certifications in welding and high-pressure pipe systems to handle industrial piping installations. Both professions mandate continuing education to maintain licensure, reflecting the evolving standards in construction safety and technology.

Tools and Equipment Used

Plumbers commonly use pipe wrenches, pipe cutters, plungers, and soldering equipment designed for installing and repairing water supply and drainage systems. Pipefitters specialize in heavy-duty tools such as threading machines, oxy-acetylene torches, welding equipment, and pipe benders for working with high-pressure piping systems in industrial settings. Both professions rely on accurate measuring tools like tape measures and levels, but pipefitters typically handle thicker materials requiring more robust machinery.

Typical Projects and Tasks

Plumbers typically handle residential and commercial water supply, drainage, and sewage systems installation and repair, including tasks like fitting pipes, fixtures, and appliances. Pipefitters specialize in industrial pipe systems used for high-pressure gases, chemicals, and steam, often working on power plants, manufacturing facilities, and refineries. Both roles require precision in reading blueprints and adhering to safety standards, but pipefitters often deal with more complex, heavy-duty piping systems.

Salary and Career Outlook

Plumbers typically earn a median annual salary of around $59,000, with job growth projected at 5% through 2031, driven by residential and commercial construction needs. Pipefitters, specializing in high-pressure systems, command higher wages averaging $64,000 per year, and their career outlook grows by 8%, fueled by industrial and energy sector demands. Both trades offer strong employment opportunities, but pipefitting provides greater earning potential and faster job growth due to specialized skills in complex piping systems.

Choosing the Right Career Path

Plumbers specialize in installing and repairing potable water systems, drainage, and sewage piping, making them essential in residential and commercial construction. Pipefitters focus on high-pressure piping systems, often working in industrial settings such as oil refineries, power plants, and manufacturing facilities. Choosing the right career path depends on your interest in working with water supply systems versus complex mechanical piping and the environment you prefer, whether residential, commercial, or industrial construction.

Plumber vs Pipefitter Infographic

jobdiv.com

jobdiv.com