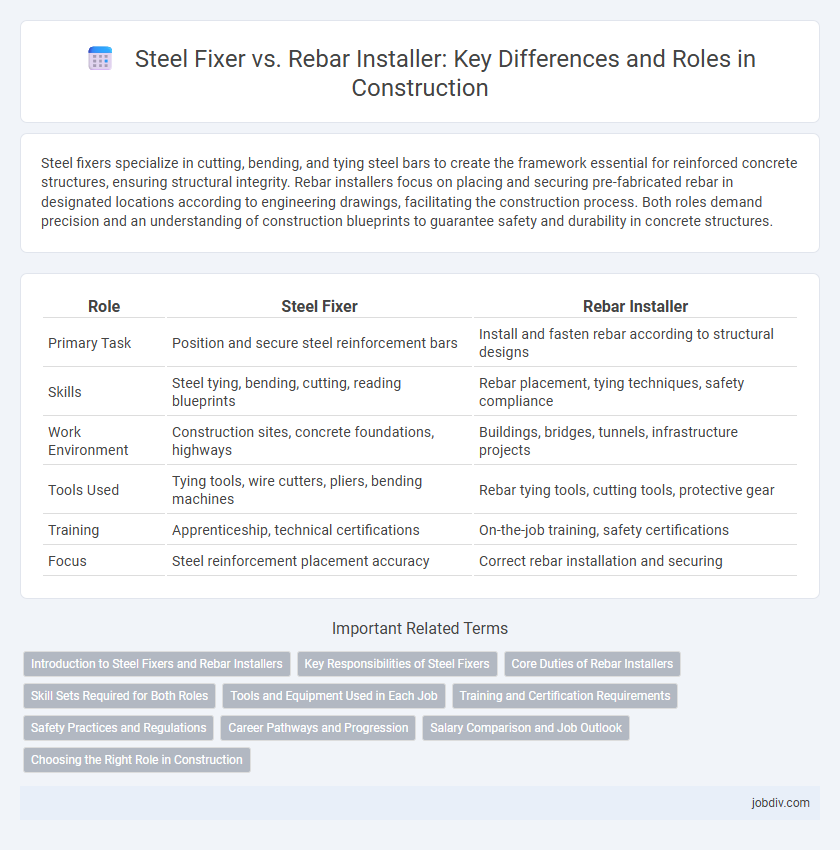

Steel fixers specialize in cutting, bending, and tying steel bars to create the framework essential for reinforced concrete structures, ensuring structural integrity. Rebar installers focus on placing and securing pre-fabricated rebar in designated locations according to engineering drawings, facilitating the construction process. Both roles demand precision and an understanding of construction blueprints to guarantee safety and durability in concrete structures.

Table of Comparison

| Role | Steel Fixer | Rebar Installer |

|---|---|---|

| Primary Task | Position and secure steel reinforcement bars | Install and fasten rebar according to structural designs |

| Skills | Steel tying, bending, cutting, reading blueprints | Rebar placement, tying techniques, safety compliance |

| Work Environment | Construction sites, concrete foundations, highways | Buildings, bridges, tunnels, infrastructure projects |

| Tools Used | Tying tools, wire cutters, pliers, bending machines | Rebar tying tools, cutting tools, protective gear |

| Training | Apprenticeship, technical certifications | On-the-job training, safety certifications |

| Focus | Steel reinforcement placement accuracy | Correct rebar installation and securing |

Introduction to Steel Fixers and Rebar Installers

Steel fixers and rebar installers specialize in positioning and securing steel reinforcement bars within concrete structures to enhance durability and strength. Steel fixers typically focus on cutting, shaping, and assembling steel bars, ensuring precise alignment according to structural blueprints. Rebar installers primarily handle the placement and tying of reinforcement bars on construction sites, contributing to the integrity of foundations, beams, and columns.

Key Responsibilities of Steel Fixers

Steel fixers are responsible for cutting, bending, and positioning steel bars and mesh according to structural blueprints to reinforce concrete in construction projects. They ensure precise placement and secure fastening of rebar to maintain the structural integrity of buildings, bridges, and other infrastructures. Steel fixers also collaborate closely with engineers and site supervisors to verify compliance with safety standards and project specifications.

Core Duties of Rebar Installers

Rebar installers specialize in positioning, cutting, and securing steel reinforcement bars (rebar) to concrete frameworks, ensuring structural integrity and compliance with engineering specifications. Their core duties include interpreting construction blueprints, accurately placing rebar according to design requirements, and tying bars together using wire to maintain stability during concrete pouring. Efficient rebar installation is crucial for enhancing the load-bearing capacity and durability of reinforced concrete structures.

Skill Sets Required for Both Roles

Steel fixers master cutting, bending, and positioning steel bars to reinforce concrete structures, requiring precise measurement and welding skills. Rebar installers specialize in assembling and securing steel reinforcement bars using tying techniques and safety compliance knowledge. Both roles demand physical strength, blueprint reading proficiency, and adherence to construction standards for structural integrity.

Tools and Equipment Used in Each Job

Steel fixers primarily use hand tools like wire cutters, pliers, tying tools, and safety equipment such as gloves and helmets to secure steel bars in reinforced concrete structures. Rebar installers rely on specialized machinery including rebar benders, cutters, and tying machines to shape, cut, and fasten reinforcing bars efficiently on large-scale construction sites. Both roles emphasize precision tools designed to ensure structural integrity and compliance with building codes.

Training and Certification Requirements

Steel fixers and rebar installers both require specialized training, with steel fixers typically undergoing apprenticeship programs that cover steel tying, cutting, and bending techniques. Rebar installers often need certification from recognized bodies such as OSHAcademy or NCCER to ensure proficiency in interpreting blueprints and securing reinforcement bars according to safety standards. Both roles demand thorough knowledge of construction codes and hands-on experience to maintain structural integrity and compliance on building sites.

Safety Practices and Regulations

Steel fixers and rebar installers must rigorously follow OSHA safety standards to prevent workplace accidents involving heavy materials and sharp tools. Proper use of personal protective equipment (PPE), such as gloves, hard hats, and safety glasses, is crucial when handling steel reinforcement bars to avoid injuries. Compliance with site-specific safety protocols and regular safety training ensures secure installation practices and reduces the risk of structural failures caused by improper reinforcement placement.

Career Pathways and Progression

Steel fixers and rebar installers both specialize in reinforcing concrete structures but differ in career pathways and progression opportunities. Steel fixers often advance to supervisory roles such as site supervisors or project managers with additional training and experience, while rebar installers may progress to specialized technical positions or foreman roles focusing on rebar detailing and layout. Both careers benefit from certifications in construction safety and trade skills, enhancing prospects for higher-level responsibilities and project leadership.

Salary Comparison and Job Outlook

Steel fixers typically earn a median annual salary of $45,000 to $60,000, while rebar installers' salaries range from $40,000 to $55,000 depending on region and experience. Job outlook for steel fixers is projected to grow 6% over the next decade, driven by infrastructure projects and urban development. Rebar installers face similar growth rates, but demand may vary slightly based on local construction trends and the types of projects requiring reinforced concrete.

Choosing the Right Role in Construction

Selecting between a steel fixer and a rebar installer hinges on project requirements and skill specialization, with steel fixers focusing on cutting, bending, and securing reinforcement steel bars, while rebar installers primarily place and tie rebar according to structural blueprints. Expertise in interpreting engineering drawings and proficiency in safety standards are critical for both roles to ensure structural integrity and compliance during concrete reinforcement. Prioritizing candidates with certifications such as OSHA training and experience with various fastening techniques enhances construction efficiency and reduces costly errors.

Steel Fixer vs Rebar Installer Infographic

jobdiv.com

jobdiv.com