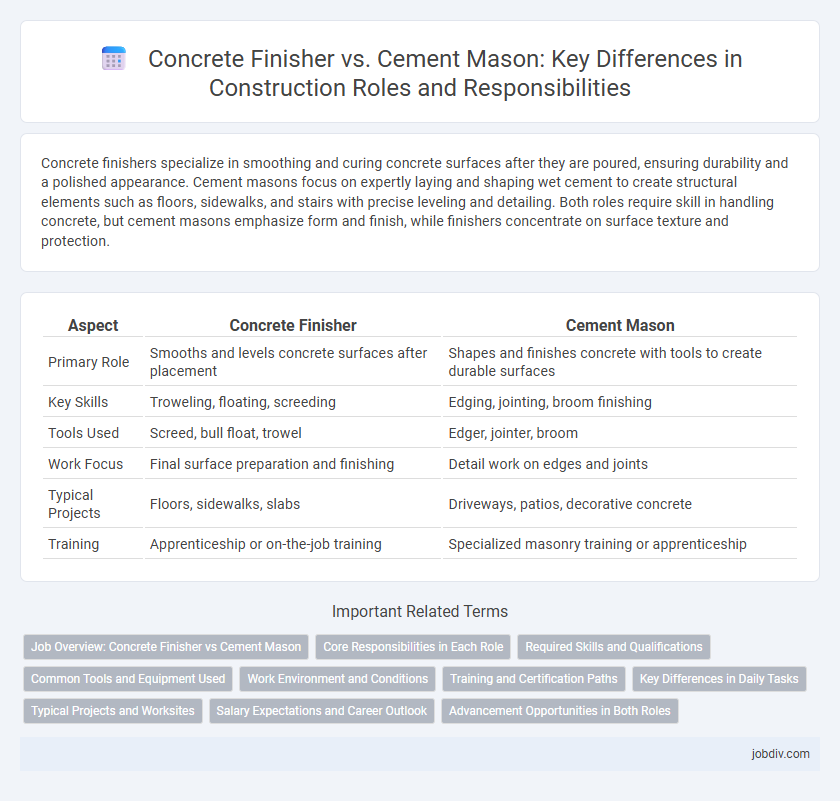

Concrete finishers specialize in smoothing and curing concrete surfaces after they are poured, ensuring durability and a polished appearance. Cement masons focus on expertly laying and shaping wet cement to create structural elements such as floors, sidewalks, and stairs with precise leveling and detailing. Both roles require skill in handling concrete, but cement masons emphasize form and finish, while finishers concentrate on surface texture and protection.

Table of Comparison

| Aspect | Concrete Finisher | Cement Mason |

|---|---|---|

| Primary Role | Smooths and levels concrete surfaces after placement | Shapes and finishes concrete with tools to create durable surfaces |

| Key Skills | Troweling, floating, screeding | Edging, jointing, broom finishing |

| Tools Used | Screed, bull float, trowel | Edger, jointer, broom |

| Work Focus | Final surface preparation and finishing | Detail work on edges and joints |

| Typical Projects | Floors, sidewalks, slabs | Driveways, patios, decorative concrete |

| Training | Apprenticeship or on-the-job training | Specialized masonry training or apprenticeship |

Job Overview: Concrete Finisher vs Cement Mason

Concrete finishers specialize in smoothing and finishing freshly poured concrete surfaces, ensuring durability and a polished appearance for structures such as sidewalks, floors, and driveways. Cement masons focus on the placement, finishing, and curing of cement-based products, emphasizing precision in jointing and texturing for enhanced strength and aesthetics. Both trades require expertise in concrete mixing, pouring, and finishing techniques, but concrete finishers prioritize surface finishing while cement masons concentrate on form and detail work.

Core Responsibilities in Each Role

Concrete finishers specialize in smoothing, leveling, and finishing poured concrete surfaces to ensure durability and aesthetic appeal. Cement masons focus on placing, shaping, and smoothing concrete during the initial pouring stages, often working with tools like floats and trowels to create precise surfaces. Both roles require expertise in concrete curing and finishing techniques but differ in timing and specific tasks during the concrete installation process.

Required Skills and Qualifications

Concrete finishers require expertise in operating hand and power tools to smooth and finish concrete surfaces, alongside skills in reading blueprints and construction plans. Cement masons must possess knowledge of concrete mixing, curing processes, and the ability to create decorative finishes, often requiring apprenticeships or vocational training. Both roles demand physical stamina, attention to detail, and familiarity with safety regulations pertinent to construction sites.

Common Tools and Equipment Used

Concrete finishers and cement masons both utilize essential tools such as trowels, floats, and screeds to shape and smooth concrete surfaces. Concrete finishers often rely on bull floats and power trowels for large-scale finishing, while cement masons frequently use hand tools like edging tools and groovers for detailed work and expansion joints. Both trades require equipment like concrete mixers, vibrating screeds, and curing blankets to ensure durable, high-quality concrete installations.

Work Environment and Conditions

Concrete finishers and cement masons often work in similar environments, including construction sites, roadways, and commercial or residential projects exposed to varying weather conditions. While both roles require working outdoors with heavy materials and machinery, concrete finishers primarily focus on smoothing and finishing surfaces after the concrete has been poured, often working under tight deadlines to ensure proper curing conditions. Cement masons additionally handle the installation and repair of concrete surfaces, frequently working in confined spaces or elevated areas, with exposure to dust, noise, and physical strain.

Training and Certification Paths

Concrete finishers typically undergo apprenticeships lasting three to four years, combining on-the-job training with technical instruction in finishing techniques, surface treatments, and curing methods. Cement masons follow a similar training path, often beginning with a formal apprenticeship program that covers slab finishing, forming joints, and applying various finishes, supplemented by certifications such as the American Concrete Institute's (ACI) Concrete Field Testing Technician or Flatwork Finisher certifications. Both roles require ongoing certification renewal to ensure updated knowledge of industry standards, safety protocols, and advanced concrete application methods.

Key Differences in Daily Tasks

Concrete finishers specialize in smoothing, leveling, and finishing freshly poured concrete surfaces, ensuring proper texture and durability for floors, sidewalks, and roads. Cement masons focus on the formation, placement, and shaping of concrete structures, including setting forms, applying curing compounds, and controlling expansion joints. While both work closely with concrete, the finisher's role is more focused on surface finishing techniques, whereas the mason handles preparation and structural detailing.

Typical Projects and Worksites

Concrete finishers typically work on large-scale projects such as highways, bridges, and commercial buildings where precise surface finishing of concrete slabs is critical. Cement masons frequently perform tasks on smaller or residential jobs, including sidewalks, driveways, patios, and curbs, focusing on shaping and detailing. Both professionals operate in construction environments but concrete finishers often tackle more extensive infrastructure worksites requiring advanced finishing techniques.

Salary Expectations and Career Outlook

Concrete finishers earn an average salary ranging from $35,000 to $60,000 annually, with experienced workers or those in specialized projects earning higher wages. Cement masons typically receive comparable pay but may have slightly higher earning potential due to their broader skill set in shaping and finishing concrete surfaces. Both careers offer steady demand driven by construction industry growth, with prospects improving as infrastructure projects and commercial developments increase nationwide.

Advancement Opportunities in Both Roles

Concrete finishers advance by mastering complex finishing techniques, such as decorative stamping and polishing, leading to supervisory or project management roles. Cement masons enhance skills in concrete mixing and form setting, enabling progression to specialized trades like concrete repair or quality control inspection. Both paths offer opportunities for certification and training, increasing prospects for higher pay and leadership positions in construction projects.

Concrete Finisher vs Cement Mason Infographic

jobdiv.com

jobdiv.com