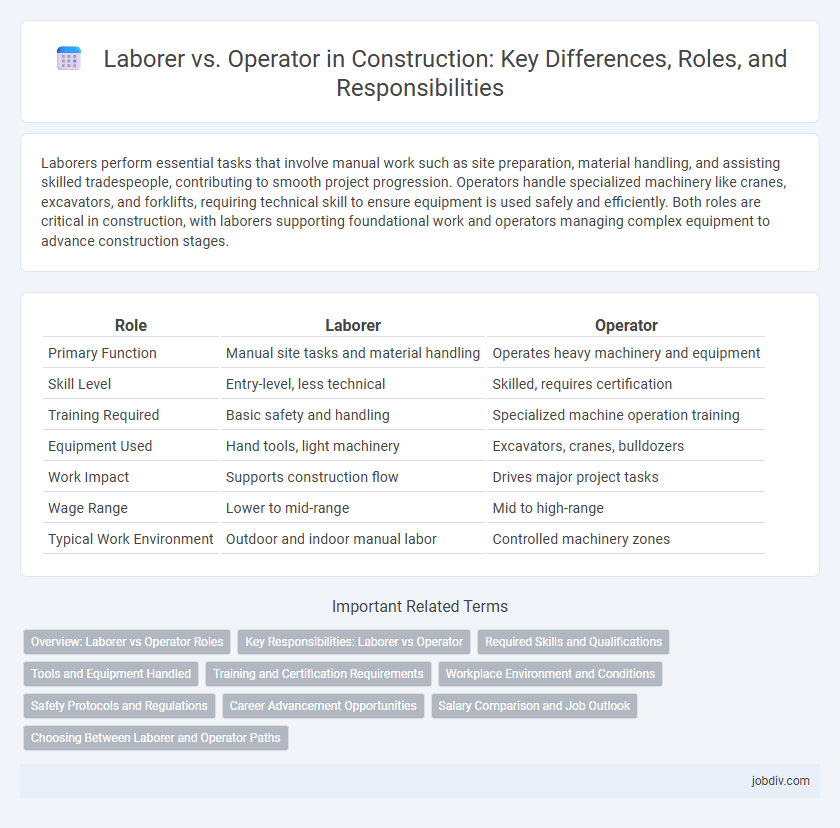

Laborers perform essential tasks that involve manual work such as site preparation, material handling, and assisting skilled tradespeople, contributing to smooth project progression. Operators handle specialized machinery like cranes, excavators, and forklifts, requiring technical skill to ensure equipment is used safely and efficiently. Both roles are critical in construction, with laborers supporting foundational work and operators managing complex equipment to advance construction stages.

Table of Comparison

| Role | Laborer | Operator |

|---|---|---|

| Primary Function | Manual site tasks and material handling | Operates heavy machinery and equipment |

| Skill Level | Entry-level, less technical | Skilled, requires certification |

| Training Required | Basic safety and handling | Specialized machine operation training |

| Equipment Used | Hand tools, light machinery | Excavators, cranes, bulldozers |

| Work Impact | Supports construction flow | Drives major project tasks |

| Wage Range | Lower to mid-range | Mid to high-range |

| Typical Work Environment | Outdoor and indoor manual labor | Controlled machinery zones |

Overview: Laborer vs Operator Roles

Laborers perform physically demanding tasks such as site preparation, material handling, and basic construction duties, supporting skilled trades and ensuring workflow efficiency. Operators specialize in controlling heavy machinery like excavators, bulldozers, and cranes, requiring technical expertise and certification to manage equipment safely on construction sites. Both roles are critical for project success, with laborers providing essential manual support and operators enabling complex machine operations.

Key Responsibilities: Laborer vs Operator

Laborers primarily handle manual tasks such as site preparation, material handling, and debris removal, ensuring the construction site remains organized and safe. Operators are responsible for managing heavy machinery like cranes, bulldozers, and excavators, requiring specialized skills to operate equipment efficiently and adhere to safety regulations. Both roles are crucial for project progression, with laborers supporting groundwork and operators enabling large-scale material movement and structural assembly.

Required Skills and Qualifications

Laborers typically require basic physical stamina, knowledge of safety protocols, and the ability to perform manual tasks with minimal technical training, often necessitating a high school diploma or equivalent. Operators must possess specialized skills in handling heavy machinery such as cranes, excavators, or forklifts, requiring formal certifications, technical training, and experience in equipment operation. Both roles demand a strong understanding of workplace safety regulations, but operators need advanced mechanical aptitude and precise control to ensure efficient and safe machine operation.

Tools and Equipment Handled

Laborers primarily handle basic hand tools such as shovels, hammers, and wheelbarrows for general site preparation and material transport, while operators manage heavy machinery including excavators, bulldozers, cranes, and forklifts for earthmoving, lifting, and site grading. The skill set for operators requires specialized training and certification to safely control sophisticated equipment, whereas laborers focus on manual tasks and support roles using simpler equipment. Efficient coordination between laborers and operators ensures optimal use of both hand tools and heavy machinery on construction projects.

Training and Certification Requirements

Laborers in construction typically need basic safety training such as OSHA 10-hour or 30-hour courses, while operators require specialized certifications for heavy machinery like cranes or bulldozers, often mandated by OSHA or state regulations. Operator certification programs include hands-on training, written exams, and practical demonstrations to ensure competence in equipment operation and safety protocols. Employers prioritize verified credentials for operators to comply with legal standards and reduce workplace accidents, whereas laborers are generally expected to complete site-specific safety orientations and receive ongoing training.

Workplace Environment and Conditions

Laborers in construction sites typically face physically demanding tasks in varied outdoor environments, often exposed to extreme weather conditions and requiring manual handling of materials. Operators work primarily with heavy machinery in controlled zones, where noise levels and vibration hazards are significant factors influencing workplace safety and comfort. Both roles require strict adherence to safety protocols, but operators benefit from enclosed cabins and ergonomic controls, while laborers rely more on personal protective equipment to mitigate environmental risks.

Safety Protocols and Regulations

Laborers and operators must adhere strictly to OSHA safety protocols tailored to their roles, including personal protective equipment (PPE) standards and machinery operation guidelines. Operators require specialized training and certification for heavy equipment use, ensuring compliance with ANSI and local safety regulations to prevent accidents. Rigorous site safety audits and regular hazard assessments are essential to maintain a secure working environment for both laborers and equipment operators.

Career Advancement Opportunities

Laborers typically start with foundational tasks, gaining valuable hands-on experience that can lead to roles such as skilled trades or supervisory positions. Operators, who control heavy machinery, often have faster career advancement within specialized equipment operation or transition into equipment maintenance and site management. Both paths offer growth, but operators generally access higher wages and advanced certifications quicker due to the technical nature of their work.

Salary Comparison and Job Outlook

Laborers in construction typically earn an average annual salary of $35,000 to $45,000, reflecting entry-level duties and manual tasks, while operators, handling heavy machinery and specialized equipment, command higher wages ranging from $50,000 to $65,000 annually. The job outlook for operators is expected to grow by 8% over the next decade due to increasing infrastructure projects and technological advancements in construction equipment. Laborer positions are projected to experience steady demand with a 5% growth rate, driven by ongoing residential and commercial building activities.

Choosing Between Laborer and Operator Paths

Choosing between laborer and operator career paths in construction depends on skill specialization and project requirements. Laborers perform essential manual tasks, offering flexibility across diverse job sites, while operators handle heavy machinery, requiring specialized training and certifications. Evaluating physical capabilities, interest in technical equipment, and long-term career goals helps determine the optimal path for construction professionals.

Laborer vs Operator Infographic

jobdiv.com

jobdiv.com