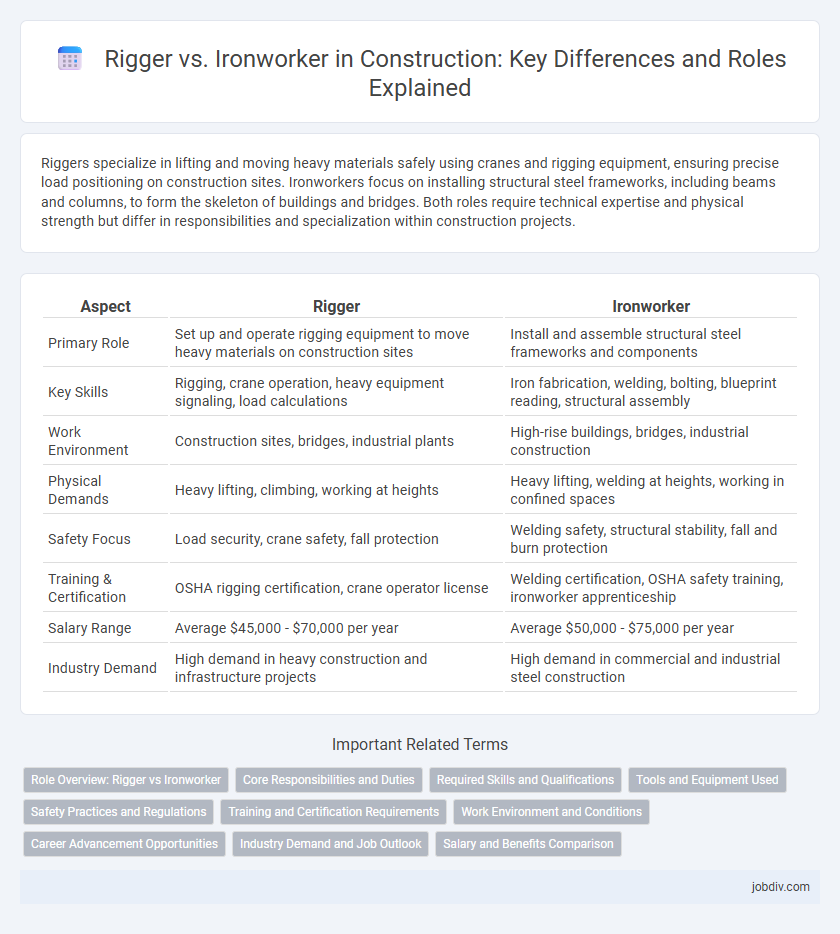

Riggers specialize in lifting and moving heavy materials safely using cranes and rigging equipment, ensuring precise load positioning on construction sites. Ironworkers focus on installing structural steel frameworks, including beams and columns, to form the skeleton of buildings and bridges. Both roles require technical expertise and physical strength but differ in responsibilities and specialization within construction projects.

Table of Comparison

| Aspect | Rigger | Ironworker |

|---|---|---|

| Primary Role | Set up and operate rigging equipment to move heavy materials on construction sites | Install and assemble structural steel frameworks and components |

| Key Skills | Rigging, crane operation, heavy equipment signaling, load calculations | Iron fabrication, welding, bolting, blueprint reading, structural assembly |

| Work Environment | Construction sites, bridges, industrial plants | High-rise buildings, bridges, industrial construction |

| Physical Demands | Heavy lifting, climbing, working at heights | Heavy lifting, welding at heights, working in confined spaces |

| Safety Focus | Load security, crane safety, fall protection | Welding safety, structural stability, fall and burn protection |

| Training & Certification | OSHA rigging certification, crane operator license | Welding certification, OSHA safety training, ironworker apprenticeship |

| Salary Range | Average $45,000 - $70,000 per year | Average $50,000 - $75,000 per year |

| Industry Demand | High demand in heavy construction and infrastructure projects | High demand in commercial and industrial steel construction |

Role Overview: Rigger vs Ironworker

Riggers specialize in lifting, moving, and securing heavy materials and equipment on construction sites using cranes, hoists, and rigging gear, ensuring safe and precise placement. Ironworkers focus on installing structural steel frameworks, reinforcing bars, and metal components that form the skeleton of buildings, bridges, and other infrastructure. Both roles require expertise in safety protocols, load calculations, and teamwork but differ in their core responsibilities and skill sets within the construction process.

Core Responsibilities and Duties

Riggers specialize in safely lifting, moving, and securing heavy loads using cranes, hoists, and rigging equipment on construction sites. Ironworkers focus on assembling, installing, and reinforcing structural steel frameworks, including bridges, buildings, and other infrastructure. Both roles demand precise coordination and adherence to safety protocols, but riggers emphasize load management while ironworkers prioritize structural assembly and stability.

Required Skills and Qualifications

Riggers require expertise in knot tying, load calculations, and crane signaling to safely lift and move heavy materials, emphasizing physical strength and coordination. Ironworkers need proficiency in welding, blueprint reading, and structural assembly, focusing on precision and compliance with safety codes. Both roles demand certification in OSHA safety standards and experience with rigging equipment and heavy machinery.

Tools and Equipment Used

Riggers primarily use slings, shackles, hoists, and wire ropes to safely lift and move heavy loads, emphasizing precision in load handling and rigging hardware. Ironworkers rely on tools such as welding machines, cutting torches, ironworkers (metalworking machines), and high-strength fasteners for steel fabrication and erection tasks. Both trades depend on personal protective equipment (PPE) like harnesses and helmets, but their toolsets differ according to their specialized roles in construction projects.

Safety Practices and Regulations

Riggers and ironworkers both adhere to strict safety practices and regulations outlined by OSHA to prevent accidents in high-risk environments such as construction sites. Riggers must ensure proper load securement and communication when moving heavy materials, while ironworkers follow precise protocols for working at heights, including fall protection and equipment inspections. Both professions require ongoing safety training and certification to comply with industry standards and reduce the risk of injury.

Training and Certification Requirements

Riggers require specialized certification such as the NCCCO Crane Signalperson and Rigger Level I and II credentials to ensure safe lifting operations, while ironworkers often pursue apprenticeship programs combined with OSHA safety training and NCCER certifications to master structural steel installation. Both professions demand rigorous hands-on training to handle heavy materials and work at heights safely, with ironworkers focusing more on welding and structural assembly techniques. Compliance with OSHA standards and industry-specific certifications is crucial in minimizing workplace hazards and enhancing job site efficiency for both roles.

Work Environment and Conditions

Riggers typically operate in dynamic outdoor environments such as construction sites, shipyards, and industrial plants where they manage heavy lifting and rigging equipment under variable weather conditions. Ironworkers often work at significant heights on steel frameworks for buildings, bridges, and infrastructure projects, facing exposure to extreme temperatures, noise, and physical hazards. Both professions require strict adherence to safety protocols, but ironworkers experience more direct risks related to falls and structural stability.

Career Advancement Opportunities

Riggers and ironworkers both have distinct career advancement pathways within the construction industry, with riggers often progressing to supervisory roles such as lead rigger or crane operator, leveraging specialized skills in load management and safety compliance. Ironworkers tend to advance to positions like foreman, superintendent, or project manager, capitalizing on expertise in structural steel installation and fabrication. Continuous certification, hands-on experience, and knowledge of industry standards significantly enhance promotion potential in both trades.

Industry Demand and Job Outlook

The demand for ironworkers continues to rise due to infrastructure projects and commercial construction growth, reflecting a strong job outlook with steady wage increases. Riggers remain essential for heavy lifting and equipment positioning in construction sites, maintaining consistent employment opportunities in industrial and energy sectors. Both professions show promising growth, but ironworkers benefit from broader application in large-scale building and bridge construction projects.

Salary and Benefits Comparison

Riggers typically earn an average annual salary ranging from $45,000 to $65,000, while ironworkers' salaries often span between $50,000 and $75,000, reflecting variations based on experience and location. Benefits for both professions frequently include health insurance, retirement plans, and paid time off, with ironworkers sometimes receiving higher union benefits due to stronger union representation. Salary growth potential tends to be more pronounced for ironworkers due to the demand for specialized skills in structural steel installation and welding.

Rigger vs Ironworker Infographic

jobdiv.com

jobdiv.com