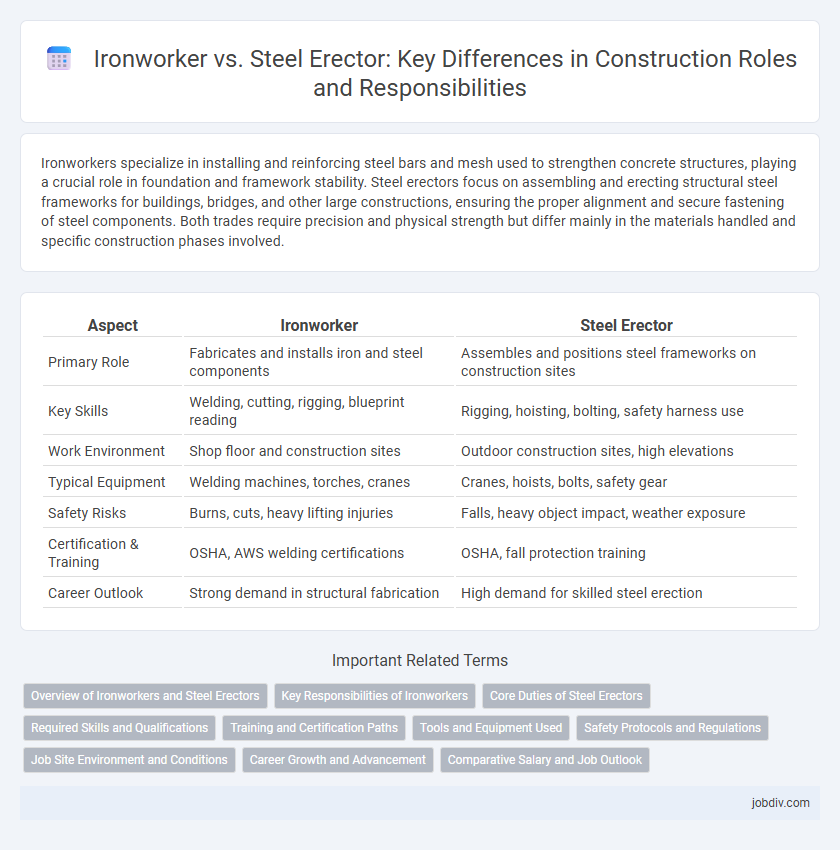

Ironworkers specialize in installing and reinforcing steel bars and mesh used to strengthen concrete structures, playing a crucial role in foundation and framework stability. Steel erectors focus on assembling and erecting structural steel frameworks for buildings, bridges, and other large constructions, ensuring the proper alignment and secure fastening of steel components. Both trades require precision and physical strength but differ mainly in the materials handled and specific construction phases involved.

Table of Comparison

| Aspect | Ironworker | Steel Erector |

|---|---|---|

| Primary Role | Fabricates and installs iron and steel components | Assembles and positions steel frameworks on construction sites |

| Key Skills | Welding, cutting, rigging, blueprint reading | Rigging, hoisting, bolting, safety harness use |

| Work Environment | Shop floor and construction sites | Outdoor construction sites, high elevations |

| Typical Equipment | Welding machines, torches, cranes | Cranes, hoists, bolts, safety gear |

| Safety Risks | Burns, cuts, heavy lifting injuries | Falls, heavy object impact, weather exposure |

| Certification & Training | OSHA, AWS welding certifications | OSHA, fall protection training |

| Career Outlook | Strong demand in structural fabrication | High demand for skilled steel erection |

Overview of Ironworkers and Steel Erectors

Ironworkers specialize in installing iron or steel girders, beams, and columns that form the skeleton of buildings, bridges, and other structures, using tools like hoists, cranes, and welding equipment. Steel erectors primarily focus on assembling structural steel components, aligning and bolting or welding steel frameworks with precision to ensure stability and safety. Both professions require in-depth knowledge of blueprints, safety protocols, and rigging techniques to construct durable steel frameworks in commercial and industrial projects.

Key Responsibilities of Ironworkers

Ironworkers specialize in the fabrication, installation, and reinforcement of steel and iron structures critical to building frameworks, bridges, and industrial facilities. Their key responsibilities include interpreting blueprints, measuring and cutting materials, assembling beams, and ensuring structural integrity through welding, bolting, and riveting. Skilled in working at heights, ironworkers also handle safety protocols to prevent accidents during steel erection projects.

Core Duties of Steel Erectors

Steel erectors specialize in assembling and installing structural steel frameworks for buildings, bridges, and other infrastructures, following precise blueprints and safety protocols. Their core duties include positioning steel beams, securing components with bolts or welds, and ensuring structural integrity through accurate alignment and measurements. These professionals operate cranes and other heavy machinery to lift steel sections, collaborating closely with ironworkers who primarily fabricate and assemble steel components off-site.

Required Skills and Qualifications

Ironworkers require proficiency in reading blueprints, operating heavy machinery, and welding techniques to fabricate and install iron components, while steel erectors specialize in interpreting structural plans, using rigging equipment, and performing precise bolting and welding to assemble steel frameworks. Both roles demand strong physical stamina, knowledge of safety protocols, and certifications such as OSHA training or NCCER credentials. Steel erectors often need advanced skills in rigging and working at heights, whereas ironworkers emphasize fabrication and reinforcement skills in concrete and steel structures.

Training and Certification Paths

Ironworkers typically undergo comprehensive apprenticeship programs lasting 3 to 4 years, combining on-the-job training with classroom instruction, and often earn certifications such as NCCER or AWS welding credentials. Steel erectors follow a similar training trajectory but may also obtain specialized certifications like OSHA safety training and rigging licenses to ensure proper handling and assembly of structural steel components. Both professions require strict adherence to safety standards and continuous skill development through industry-recognized certifications to advance in the construction sector.

Tools and Equipment Used

Ironworkers primarily use hand tools such as hammers, wrenches, and impact drivers, along with cutting torches and welding machines for shaping and joining metal components. Steel erectors rely on heavy machinery like cranes, hoists, and rigging equipment to lift, position, and secure steel beams during structural assembly. Both professionals require safety gear including harnesses, helmets, and gloves to operate effectively in high-risk construction environments.

Safety Protocols and Regulations

Ironworkers and steel erectors both adhere to strict OSHA safety standards, but ironworkers face higher risks related to welding, cutting, and rebar installation requiring specialized protective gear and gas monitoring. Steel erectors focus heavily on fall protection systems and load handling protocols as they assemble large structural frameworks at height, following ANSI and OSHA regulations on scaffold use and crane operation. Compliance with these industry-specific safety procedures reduces workplace accidents and ensures regulatory adherence on construction sites.

Job Site Environment and Conditions

Ironworkers and steel erectors both operate in high-elevation construction site environments, often exposed to extreme weather conditions and requiring strict safety protocols. Ironworkers focus on fabricating, cutting, and installing iron or steel components in settings like bridges, buildings, and towers, whereas steel erectors specialize in assembling and securing steel frameworks, frequently using cranes and rigging equipment. Both roles demand physical endurance, precision, and adherence to occupational safety standards to manage hazards such as falls, heavy machinery, and structural instability.

Career Growth and Advancement

Ironworkers and steel erectors both play critical roles in construction, but career growth for ironworkers often extends into specialized welding, rigging, and supervisory positions due to their involvement in reinforcing concrete and securing structural frameworks. Steel erectors focus on assembling steel frameworks and may advance by becoming foremen, project managers, or safety coordinators within large-scale construction projects. Both career paths offer opportunities for certification and skill development, enhancing prospects for higher wages and leadership roles in the construction industry.

Comparative Salary and Job Outlook

Ironworkers typically earn an average annual salary ranging from $45,000 to $75,000, while steel erectors can expect salaries between $50,000 and $80,000 due to the specialized nature of their work. The job outlook for steel erectors is projected to grow by 8% over the next decade, slightly faster than the 6% growth rate forecasted for ironworkers, reflecting increased demand for steel framework in infrastructure projects. Both professions benefit from steady employment opportunities driven by ongoing construction and urban development across the United States.

Ironworker vs Steel Erector Infographic

jobdiv.com

jobdiv.com