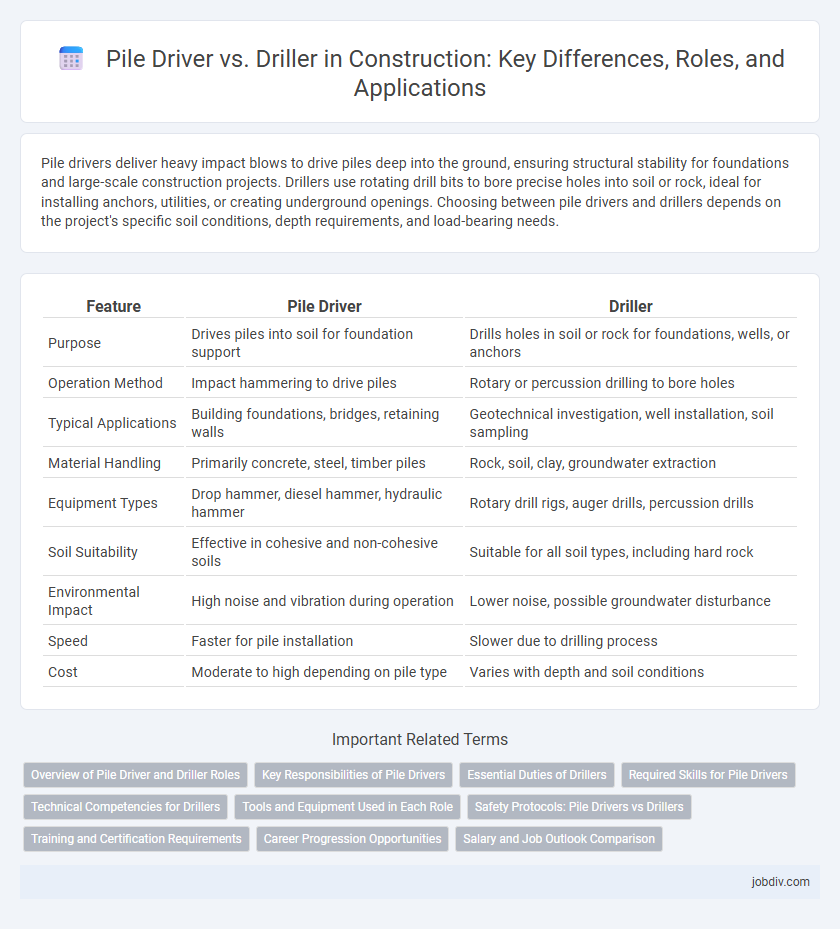

Pile drivers deliver heavy impact blows to drive piles deep into the ground, ensuring structural stability for foundations and large-scale construction projects. Drillers use rotating drill bits to bore precise holes into soil or rock, ideal for installing anchors, utilities, or creating underground openings. Choosing between pile drivers and drillers depends on the project's specific soil conditions, depth requirements, and load-bearing needs.

Table of Comparison

| Feature | Pile Driver | Driller |

|---|---|---|

| Purpose | Drives piles into soil for foundation support | Drills holes in soil or rock for foundations, wells, or anchors |

| Operation Method | Impact hammering to drive piles | Rotary or percussion drilling to bore holes |

| Typical Applications | Building foundations, bridges, retaining walls | Geotechnical investigation, well installation, soil sampling |

| Material Handling | Primarily concrete, steel, timber piles | Rock, soil, clay, groundwater extraction |

| Equipment Types | Drop hammer, diesel hammer, hydraulic hammer | Rotary drill rigs, auger drills, percussion drills |

| Soil Suitability | Effective in cohesive and non-cohesive soils | Suitable for all soil types, including hard rock |

| Environmental Impact | High noise and vibration during operation | Lower noise, possible groundwater disturbance |

| Speed | Faster for pile installation | Slower due to drilling process |

| Cost | Moderate to high depending on pile type | Varies with depth and soil conditions |

Overview of Pile Driver and Driller Roles

Pile drivers and drillers serve distinct roles in construction site foundation work, where pile drivers are specialized in driving piles deep into the ground to provide structural support for buildings and bridges. Drillers focus on creating precise boreholes by rotary or percussion drilling methods for installing foundations, utilities, or soil sampling. Both roles require specialized equipment and expertise to ensure the stability and integrity of construction projects.

Key Responsibilities of Pile Drivers

Pile drivers are responsible for driving piles into the soil to provide deep foundation support for structures such as buildings, bridges, and piers. They operate heavy machinery like hydraulic or diesel hammers to ensure piles reach the required depth and load-bearing capacity. Accurate alignment and monitoring of pile placement are critical to maintaining structural integrity and project safety.

Essential Duties of Drillers

Drillers are responsible for operating and maintaining drilling equipment to create precise boreholes for foundation piles, ensuring soil stability and load-bearing capacity. They monitor drilling parameters, including pressure, rotation speed, and penetration rate, to optimize performance and prevent equipment failure. Accurate alignment and depth control performed by drillers are crucial for the structural integrity of constructed foundations.

Required Skills for Pile Drivers

Pile drivers require specialized skills in operating heavy machinery designed to drive piles into soil or concrete to provide foundational support for structures. These operators must understand soil conditions, equipment mechanics, and safety protocols to ensure precise pile placement and structural integrity. Proficiency in interpreting blueprints and coordinating with construction teams is critical for effective pile driving.

Technical Competencies for Drillers

Drillers in construction exhibit technical competencies such as precise borehole alignment, soil stabilization techniques, and effective management of drilling mud to maintain borehole integrity. Mastery in operating various drill rigs, understanding geological formations, and implementing safety protocols ensures efficient and accurate hole creation for foundation piles. Their proficiency in monitoring drilling parameters minimizes equipment wear and enhances overall project quality.

Tools and Equipment Used in Each Role

Pile drivers use heavy-duty equipment such as diesel hammers, hydraulic impact hammers, and vibratory drivers to install deep foundation piles efficiently. Drillers rely on rotary drilling rigs, augers, and core drill machines designed for creating precise boreholes or extracting soil and rock samples. Both roles require specialized machinery tailored to specific foundation tasks, with pile drivers emphasizing impact force and drillers focusing on rotational cutting and soil removal.

Safety Protocols: Pile Drivers vs Drillers

Pile drivers require strict safety protocols due to their heavy impact vibrations and noise levels, necessitating reinforced barriers and personal protective equipment (PPE) like ear protection and hard hats. Drill rigs demand precise operational safety measures to prevent hazards such as falling debris and equipment entanglement, with emphasis on securing drill zones and continuous equipment inspections. Both machines mandate comprehensive training programs for operators and adherence to OSHA standards to minimize workplace accidents and ensure site safety.

Training and Certification Requirements

Pile driver operators typically require specialized training in heavy machinery operation, safety protocols, and site-specific procedures, often supported by certifications such as OSHA or NCCCO. Driller certifications emphasize technical knowledge of drilling equipment, geology, and hazard recognition, with programs like API Rig Pass or IWCF ensuring competence in safe drilling practices. Both roles demand continuous education to comply with evolving industry standards and enhance workplace safety.

Career Progression Opportunities

Pile drivers offer career progression through specialized roles in foundation construction, project management, and equipment operation, leveraging their expertise in heavy machinery and site preparation. Drillers can advance by mastering advanced drilling techniques, equipment maintenance, and moving into supervisory positions within geotechnical investigation or resource extraction projects. Both careers provide pathways to leadership and technical specialization, with differing industry focuses influencing long-term growth opportunities.

Salary and Job Outlook Comparison

Pile drivers typically earn a median salary of $55,000 to $70,000 annually, while drillers' salaries range from $50,000 to $65,000, depending on experience and location. The job outlook for pile drivers shows steady growth due to ongoing infrastructure projects, with a projected employment increase of 5% over the next decade. Drillers face a more variable job market influenced by fluctuations in construction and energy sectors but maintain moderate demand with growth estimated around 3%.

Pile Driver vs Driller Infographic

jobdiv.com

jobdiv.com