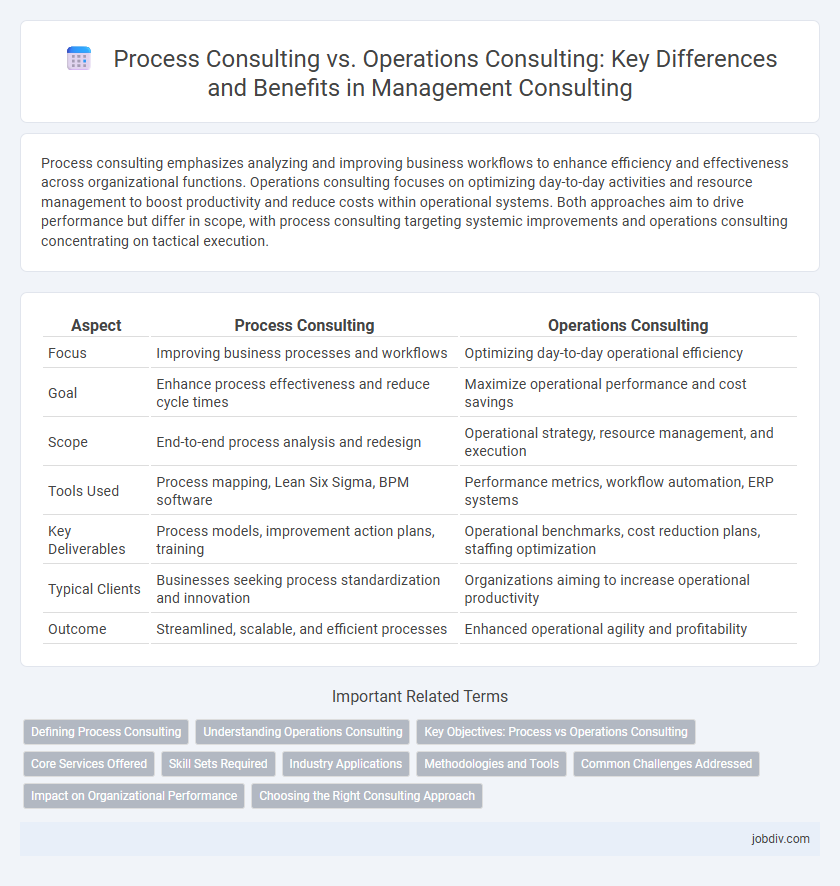

Process consulting emphasizes analyzing and improving business workflows to enhance efficiency and effectiveness across organizational functions. Operations consulting focuses on optimizing day-to-day activities and resource management to boost productivity and reduce costs within operational systems. Both approaches aim to drive performance but differ in scope, with process consulting targeting systemic improvements and operations consulting concentrating on tactical execution.

Table of Comparison

| Aspect | Process Consulting | Operations Consulting |

|---|---|---|

| Focus | Improving business processes and workflows | Optimizing day-to-day operational efficiency |

| Goal | Enhance process effectiveness and reduce cycle times | Maximize operational performance and cost savings |

| Scope | End-to-end process analysis and redesign | Operational strategy, resource management, and execution |

| Tools Used | Process mapping, Lean Six Sigma, BPM software | Performance metrics, workflow automation, ERP systems |

| Key Deliverables | Process models, improvement action plans, training | Operational benchmarks, cost reduction plans, staffing optimization |

| Typical Clients | Businesses seeking process standardization and innovation | Organizations aiming to increase operational productivity |

| Outcome | Streamlined, scalable, and efficient processes | Enhanced operational agility and profitability |

Defining Process Consulting

Process consulting centers on analyzing and improving business workflows to enhance efficiency and align operations with strategic goals. It involves mapping existing processes, identifying bottlenecks, and recommending tailored solutions for optimized performance. This approach differs from operations consulting by emphasizing process design and effectiveness rather than daily operational management.

Understanding Operations Consulting

Operations consulting focuses on optimizing core business processes to improve efficiency, reduce costs, and enhance overall performance. It involves analyzing workflows, supply chain management, and resource allocation to identify bottlenecks and implement scalable solutions. Key areas include process improvement, technology integration, and change management to drive sustainable operational excellence.

Key Objectives: Process vs Operations Consulting

Process consulting primarily targets the optimization and redesign of specific workflows to enhance efficiency, reduce bottlenecks, and improve quality within business functions. Operations consulting focuses on the broader system of organizational activities, aiming to streamline supply chains, improve resource allocation, and boost overall operational performance. Key objectives for process consulting center on granular process improvements, while operations consulting addresses end-to-end operational effectiveness and cost reduction across multiple departments.

Core Services Offered

Process consulting focuses on analyzing and improving business workflows, identifying inefficiencies, and designing optimized procedures to enhance overall performance. Operations consulting centers on enhancing day-to-day activities, resource management, and supply chain optimization to increase productivity and reduce operational costs. Core services in process consulting include process mapping, performance analysis, and change management, while operations consulting offers services like operational strategy development, logistics planning, and capacity optimization.

Skill Sets Required

Process consulting requires expertise in workflow analysis, change management, and process reengineering to optimize business procedures and enhance efficiency. Operations consulting demands strong skills in supply chain management, cost reduction, and performance measurement to improve day-to-day functional operations. Both fields value analytical thinking, problem-solving abilities, and effective communication for successful client collaboration and project execution.

Industry Applications

Process consulting emphasizes analyzing and improving specific workflows within industries such as manufacturing, healthcare, and finance to enhance efficiency and reduce waste. Operations consulting targets broader organizational functions including supply chain management, resource allocation, and production planning, often applied in retail, logistics, and telecommunications sectors. Both consulting types utilize data-driven strategies and industry-specific benchmarks to optimize performance and drive sustainable growth.

Methodologies and Tools

Process consulting emphasizes methodologies like BPMN (Business Process Model and Notation) and Six Sigma to analyze and redesign workflows for enhanced efficiency. Operations consulting utilizes tools such as Lean Management and ERP (Enterprise Resource Planning) systems to optimize resource allocation and operational performance. Both approaches leverage data analytics and process simulation software for informed decision-making and continuous improvement.

Common Challenges Addressed

Process consulting primarily addresses challenges related to workflow inefficiencies, unclear process documentation, and bottlenecks that hinder productivity. Operations consulting focuses on overcoming issues such as resource allocation, supply chain disruptions, and performance measurement gaps. Both approaches aim to optimize organizational effectiveness by targeting distinct but often overlapping operational pain points.

Impact on Organizational Performance

Process consulting enhances organizational performance by streamlining workflows, reducing inefficiencies, and fostering continuous improvement, which leads to higher productivity and quality output. Operations consulting directly targets operational effectiveness through cost reduction, resource optimization, and supply chain management, driving immediate improvements in profitability and scalability. Both approaches complement each other by addressing underlying process bottlenecks and operational execution to maximize overall organizational performance.

Choosing the Right Consulting Approach

Process consulting emphasizes identifying and improving workflows to enhance efficiency, while operations consulting focuses on optimizing day-to-day business functions for better performance. Selecting the right consulting approach depends on a company's specific challenges, whether they require strategic process redesign or operational problem-solving. Evaluating organizational goals and existing inefficiencies ensures the chosen consulting method delivers targeted, measurable improvements.

Process Consulting vs Operations Consulting Infographic

jobdiv.com

jobdiv.com