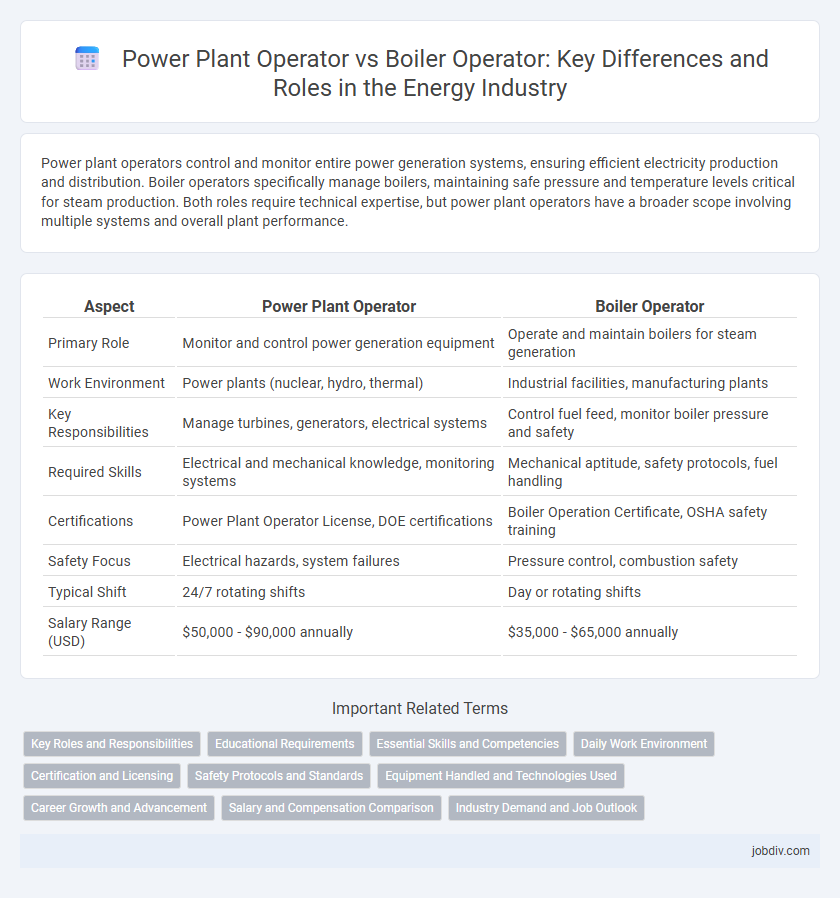

Power plant operators control and monitor entire power generation systems, ensuring efficient electricity production and distribution. Boiler operators specifically manage boilers, maintaining safe pressure and temperature levels critical for steam production. Both roles require technical expertise, but power plant operators have a broader scope involving multiple systems and overall plant performance.

Table of Comparison

| Aspect | Power Plant Operator | Boiler Operator |

|---|---|---|

| Primary Role | Monitor and control power generation equipment | Operate and maintain boilers for steam generation |

| Work Environment | Power plants (nuclear, hydro, thermal) | Industrial facilities, manufacturing plants |

| Key Responsibilities | Manage turbines, generators, electrical systems | Control fuel feed, monitor boiler pressure and safety |

| Required Skills | Electrical and mechanical knowledge, monitoring systems | Mechanical aptitude, safety protocols, fuel handling |

| Certifications | Power Plant Operator License, DOE certifications | Boiler Operation Certificate, OSHA safety training |

| Safety Focus | Electrical hazards, system failures | Pressure control, combustion safety |

| Typical Shift | 24/7 rotating shifts | Day or rotating shifts |

| Salary Range (USD) | $50,000 - $90,000 annually | $35,000 - $65,000 annually |

Key Roles and Responsibilities

Power Plant Operators oversee the operation and maintenance of entire power generation systems, ensuring efficient electricity production, monitoring control systems, and responding to emergencies. Boiler Operators specialize in managing and maintaining boilers that generate steam, controlling fuel supply and pressure levels to ensure safe and consistent steam output. Both roles demand strict adherence to safety protocols, but Power Plant Operators handle broader system coordination, while Boiler Operators focus on boiler-specific operations and maintenance.

Educational Requirements

Power plant operators typically require a high school diploma or equivalent, supplemented by extensive on-the-job training and often completion of a technical certification program in power generation or electrical systems. Boiler operators need a high school diploma or GED, along with specialized training in boiler operation, maintenance, and safety regulations, frequently obtained through apprenticeships or vocational schools. Both roles emphasize knowledge of mechanical systems and safety protocols, but power plant operators generally require broader technical education to manage complex power generation equipment.

Essential Skills and Competencies

Power plant operators must master complex control systems, monitoring equipment performance, and managing energy output efficiently to ensure continuous power generation. Boiler operators require expertise in managing boiler pressure, temperature control, fuel combustion, and adhering to safety protocols to maintain optimal steam production. Both roles demand strong troubleshooting abilities, mechanical aptitude, and a thorough understanding of regulatory compliance and safety standards in energy production.

Daily Work Environment

Power Plant Operators manage entire power generation systems, overseeing control rooms and coordinating equipment performance to ensure continuous electricity supply. Boiler Operators focus on monitoring and maintaining boiler systems, working closely with high-pressure steam equipment in physically demanding and often noisy environments. Both roles require adherence to safety protocols and real-time problem-solving but differ in scale and operational scope within energy production facilities.

Certification and Licensing

Power Plant Operators require certifications such as the Certified Power Plant Operator credential, often mandated by employers and regulatory agencies, ensuring proficiency in managing complex electrical systems. Boiler Operators must obtain specific licenses like the Boiler Operator's License, regulated by state or local authorities, proving expertise in safe boiler operation and maintenance. Both roles demand compliance with safety standards and ongoing education to maintain certifications and licenses critical in the energy sector.

Safety Protocols and Standards

Power Plant Operators adhere to rigorous safety protocols such as the Occupational Safety and Health Administration (OSHA) standards and the North American Electric Reliability Corporation (NERC) regulations to prevent electrical hazards and ensure grid stability. Boiler Operators must comply with the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code and perform regular inspections to prevent pressure-related accidents and maintain steam system integrity. Both roles require strict adherence to lockout/tagout procedures and use of personal protective equipment (PPE) to minimize risks in high-temperature and high-voltage environments.

Equipment Handled and Technologies Used

Power plant operators manage complex energy generation equipment such as turbines, generators, and control systems to ensure consistent electricity production. Boiler operators specialize in operating and maintaining boilers and associated steam generation technology, focusing on temperature, pressure controls, and fuel feed mechanisms. Both roles require knowledge of automated control systems and safety protocols, but power plant operators work with a broader range of machinery compared to the more specialized boiler equipment handled by boiler operators.

Career Growth and Advancement

Power plant operators typically experience broader career growth opportunities due to their oversight of entire power generation processes, including turbine and generator management, which positions them for supervisory or technical specialist roles. Boiler operators concentrate on the operation and maintenance of boilers, offering advancement primarily within boiler management or HVAC control systems, often leading to senior technician or maintenance supervisor positions. Both careers benefit from certifications and continuous training, but power plant operators generally have a wider range of progression paths in the energy sector.

Salary and Compensation Comparison

Power plant operators typically earn a median annual salary of around $85,000, while boiler operators have a lower median salary closer to $60,000, reflecting differences in operational scope and technical responsibilities. Compensation packages for power plant operators often include performance bonuses and higher overtime pay due to the complexity of managing large-scale energy production systems. Boiler operators receive more modest benefits, with wages influenced by regional demand and plant type.

Industry Demand and Job Outlook

Power plant operators and boiler operators both play critical roles in the energy sector, with power plant operators overseeing the entire operation of power generation facilities, while boiler operators focus specifically on managing and maintaining boilers. Industry demand for power plant operators is growing moderately due to the shift toward renewable energy sources, requiring operators to adapt to newer technologies. Boiler operators, however, face a more stable yet niche job outlook concentrated in industries relying on steam boilers, including manufacturing and chemical plants.

Power Plant Operator vs Boiler Operator Infographic

jobdiv.com

jobdiv.com