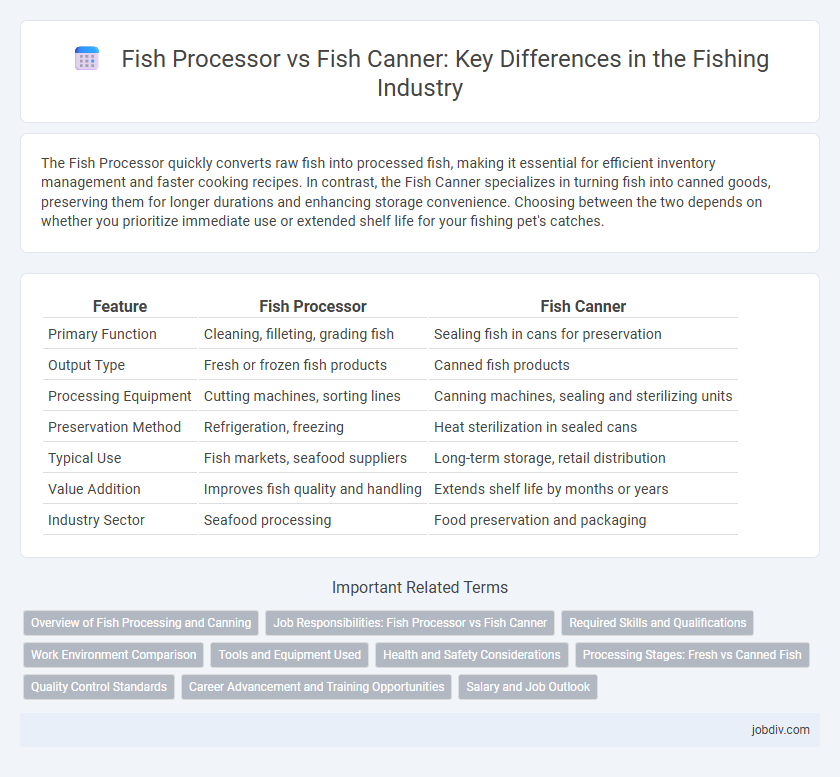

The Fish Processor quickly converts raw fish into processed fish, making it essential for efficient inventory management and faster cooking recipes. In contrast, the Fish Canner specializes in turning fish into canned goods, preserving them for longer durations and enhancing storage convenience. Choosing between the two depends on whether you prioritize immediate use or extended shelf life for your fishing pet's catches.

Table of Comparison

| Feature | Fish Processor | Fish Canner |

|---|---|---|

| Primary Function | Cleaning, filleting, grading fish | Sealing fish in cans for preservation |

| Output Type | Fresh or frozen fish products | Canned fish products |

| Processing Equipment | Cutting machines, sorting lines | Canning machines, sealing and sterilizing units |

| Preservation Method | Refrigeration, freezing | Heat sterilization in sealed cans |

| Typical Use | Fish markets, seafood suppliers | Long-term storage, retail distribution |

| Value Addition | Improves fish quality and handling | Extends shelf life by months or years |

| Industry Sector | Seafood processing | Food preservation and packaging |

Overview of Fish Processing and Canning

Fish processing involves a series of steps such as cleaning, filleting, freezing, and packaging to prepare fish for consumption or further manufacturing. Fish canning specifically refers to the method of preserving fish through sealing in airtight containers and heat sterilization, extending shelf life and maintaining nutritional value. Both fish processors and canners play critical roles in the seafood supply chain, optimizing product quality and safety for global distribution.

Job Responsibilities: Fish Processor vs Fish Canner

Fish processors are primarily responsible for cleaning, filleting, and preparing fish for packaging or sale, ensuring freshness and quality control throughout the process. Fish canners focus on controlling the canning process, including sterilization, packing fish into cans, sealing, and maintaining strict hygiene standards to guarantee product safety. Both roles require adherence to safety regulations and quality assurance but differ in the specific production stages they manage within the seafood industry.

Required Skills and Qualifications

Fish processors require strong knowledge of seafood handling, filleting techniques, and quality control standards to ensure freshness and safety. Fish canners must possess expertise in sterilization processes, packaging technology, and adherence to food safety regulations critical for long-term preservation. Both roles demand attention to detail, manual dexterity, and compliance with hygiene protocols in a seafood processing environment.

Work Environment Comparison

Fish processors operate primarily in cold, wet environments with constant exposure to raw fish, requiring stringent hygiene and temperature control measures to maintain product quality. Fish canners work in sterile, heat-intensive settings where automated machinery seals fish into cans under high pressure, demanding rigorous safety and sanitation standards to prevent contamination. Both roles involve repetitive tasks but differ significantly in physical conditions, with processors facing more manual labor and canners managing mechanized production lines.

Tools and Equipment Used

Fish processors use automated cutting machines, deboners, and filleting tables designed for precision and speed to prepare fish for retail or further processing. Fish canners rely on sealing machines, retorts, and sterilizers to ensure the fish is preserved safely in cans, focusing on equipment that controls temperature and pressure. Both industries utilize refrigeration units and quality control tools, but their machinery reflects the distinct end products and production workflows.

Health and Safety Considerations

Fish processors prioritize maintaining strict hygiene protocols and temperature controls to prevent contamination and ensure product safety during filleting and packaging. Fish canners adhere to robust sterilization processes involving high-heat treatment to eliminate pathogens and extend shelf life while safeguarding nutritional quality. Both roles require rigorous compliance with health regulations, though fish canning demands additional attention to pressure and vacuum system safety to prevent botulism risks.

Processing Stages: Fresh vs Canned Fish

Fish processors handle fresh fish through stages such as cleaning, gutting, filleting, and chilling to preserve texture and flavor before distribution. Fish canners focus on additional steps like cooking, sterilizing, and sealing fish in cans to ensure long shelf life and safety. The key difference lies in processing stages where fresh fish maintain quality for immediate consumption, whereas canned fish prioritize extended preservation.

Quality Control Standards

Fish processors implement stringent quality control standards involving thorough inspection, grading, and hygiene protocols to ensure freshness and safety throughout the handling and packaging stages. Fish canners focus quality control on maintaining product integrity during cooking and sealing processes, using sterilization techniques to prevent contamination and extend shelf life. Both roles demand compliance with regulatory guidelines such as HACCP and FDA standards to uphold consumer safety and product consistency.

Career Advancement and Training Opportunities

Fish processors develop skills in sorting, filleting, and quality control, with opportunities to advance into supervisory roles or specialize in seafood safety and packaging technology. Fish canners receive training in sterilization processes, machine operation, and quality assurance, enabling career progression toward production management or technical maintenance positions. Both careers offer specialized training programs that enhance expertise and open pathways to leadership roles within the seafood industry.

Salary and Job Outlook

Fish processors earn an average salary ranging from $28,000 to $40,000 annually, reflecting entry-level to mid-career experience, while fish canners typically earn slightly lower wages, averaging $25,000 to $35,000 per year. Job outlook for fish processors remains stable due to consistent demand in seafood processing, with moderate growth driven by advancements in technology and sustainable fishing practices. Fish canners face a more limited job outlook influenced by automation and seasonal work fluctuations, which can constrain long-term employment opportunities.

Fish Processor vs Fish Canner Infographic

jobdiv.com

jobdiv.com