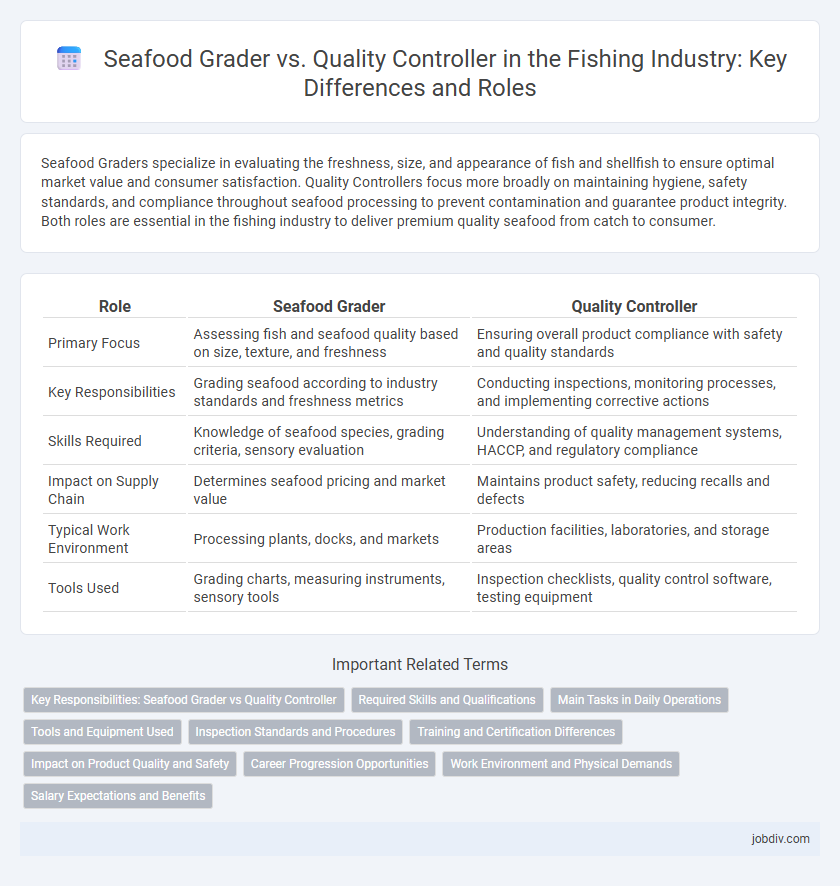

Seafood Graders specialize in evaluating the freshness, size, and appearance of fish and shellfish to ensure optimal market value and consumer satisfaction. Quality Controllers focus more broadly on maintaining hygiene, safety standards, and compliance throughout seafood processing to prevent contamination and guarantee product integrity. Both roles are essential in the fishing industry to deliver premium quality seafood from catch to consumer.

Table of Comparison

| Role | Seafood Grader | Quality Controller |

|---|---|---|

| Primary Focus | Assessing fish and seafood quality based on size, texture, and freshness | Ensuring overall product compliance with safety and quality standards |

| Key Responsibilities | Grading seafood according to industry standards and freshness metrics | Conducting inspections, monitoring processes, and implementing corrective actions |

| Skills Required | Knowledge of seafood species, grading criteria, sensory evaluation | Understanding of quality management systems, HACCP, and regulatory compliance |

| Impact on Supply Chain | Determines seafood pricing and market value | Maintains product safety, reducing recalls and defects |

| Typical Work Environment | Processing plants, docks, and markets | Production facilities, laboratories, and storage areas |

| Tools Used | Grading charts, measuring instruments, sensory tools | Inspection checklists, quality control software, testing equipment |

Key Responsibilities: Seafood Grader vs Quality Controller

Seafood Graders are responsible for assessing the size, texture, color, and freshness of seafood to categorize products according to established grading standards, ensuring consistency before distribution. Quality Controllers oversee the entire production process, from raw material inspection to packaging, implementing strict hygiene protocols and monitoring for contaminants to guarantee compliance with food safety regulations. Both roles work collaboratively to maintain product integrity, with Graders focusing on classification and Quality Controllers emphasizing regulatory adherence and quality assurance.

Required Skills and Qualifications

Seafood Graders require keen sensory evaluation skills, knowledge of fish species, grading standards, and experience with quality assessment tools to ensure product classification. Quality Controllers need expertise in food safety regulations, quality management systems, laboratory testing procedures, and strong analytical abilities to monitor and maintain seafood processing standards. Both roles demand attention to detail and understanding of handling practices but diverge with Graders focusing on visual and tactile inspection while Controllers emphasize compliance and process verification.

Main Tasks in Daily Operations

Seafood graders focus on categorizing catches based on size, weight, and species to ensure compliance with market standards and optimize packaging efficiency. Quality controllers conduct rigorous inspections for freshness, contamination, and adherence to safety regulations, utilizing sensory evaluations and laboratory testing. Both roles collaborate closely to maintain product excellence, reduce waste, and uphold regulatory compliance throughout the seafood supply chain.

Tools and Equipment Used

Seafood graders primarily use automated sorting machines, digital weighing scales, and color analyzers to categorize seafood based on size, weight, and freshness. Quality controllers rely on tools such as microscopes, pH meters, and temperature loggers to assess the hygienic conditions and biochemical properties of seafood products. Both roles utilize specialized software for data recording and traceability to ensure compliance with industry standards.

Inspection Standards and Procedures

Seafood graders focus on assessing the size, weight, and external quality of fish according to strict grading standards set by regulatory bodies such as the Food and Agriculture Organization (FAO). Quality controllers perform comprehensive inspections that include microbiological testing, temperature monitoring, and contamination checks to ensure compliance with food safety regulations like HACCP. Both roles require adherence to industry-specific protocols, but quality controllers implement broader quality assurance procedures beyond surface-level grading.

Training and Certification Differences

Seafood graders undergo specialized training focused on evaluating fish based on size, color, texture, and freshness to ensure compliance with industry standards, often requiring certification from bodies like the National Seafood HACCP Alliance. Quality controllers receive broader training encompassing hazard analysis, product testing, and regulatory compliance, with certifications including HACCP, ISO 22000, or SQF programs. The key distinction lies in graders being certified for sensory and grading techniques, while quality controllers are certified for comprehensive quality assurance and safety management.

Impact on Product Quality and Safety

Seafood graders play a crucial role in categorizing fish based on size, species, and freshness, directly influencing market value and consumer perception. Quality controllers implement strict safety protocols, conducting microbial and chemical tests to ensure compliance with food safety standards. Together, their combined efforts enhance product quality and mitigate health risks associated with seafood consumption.

Career Progression Opportunities

Seafood Graders primarily focus on assessing product quality to ensure compliance with industry standards, serving as a foundational role in the seafood processing sector. Career progression often leads to positions like Quality Controller, where responsibilities expand to managing quality assurance systems and overseeing regulatory adherence. This advancement offers increased leadership opportunities, higher salaries, and greater influence on overall product standards and operational efficiency within seafood companies.

Work Environment and Physical Demands

Seafood graders typically work in cold, wet environments such as processing plants or docks, requiring sustained standing and repetitive hand movements to inspect fish and shellfish for size, weight, and quality. Quality controllers operate in similar settings but face higher responsibility for maintaining hygiene standards and compliance, often involving detailed inspections and documentation tasks under time pressure. Both roles demand physical stamina and attention to detail, but quality controllers may experience additional stress due to regulatory oversight and problem-solving requirements.

Salary Expectations and Benefits

Seafood graders typically earn between $30,000 and $45,000 annually, focusing on assessing fish quality and sorting products based on size and freshness, with benefits often including health insurance and paid leave. Quality controllers in the fishing industry command higher salaries ranging from $40,000 to $60,000, responsible for monitoring compliance with safety standards and conducting product inspections, often receiving additional perks such as performance bonuses and professional development opportunities. Both roles contribute to seafood safety, but quality controllers generally have greater salary expectations due to their regulatory responsibilities and technical expertise.

Seafood Grader vs Quality Controller Infographic

jobdiv.com

jobdiv.com