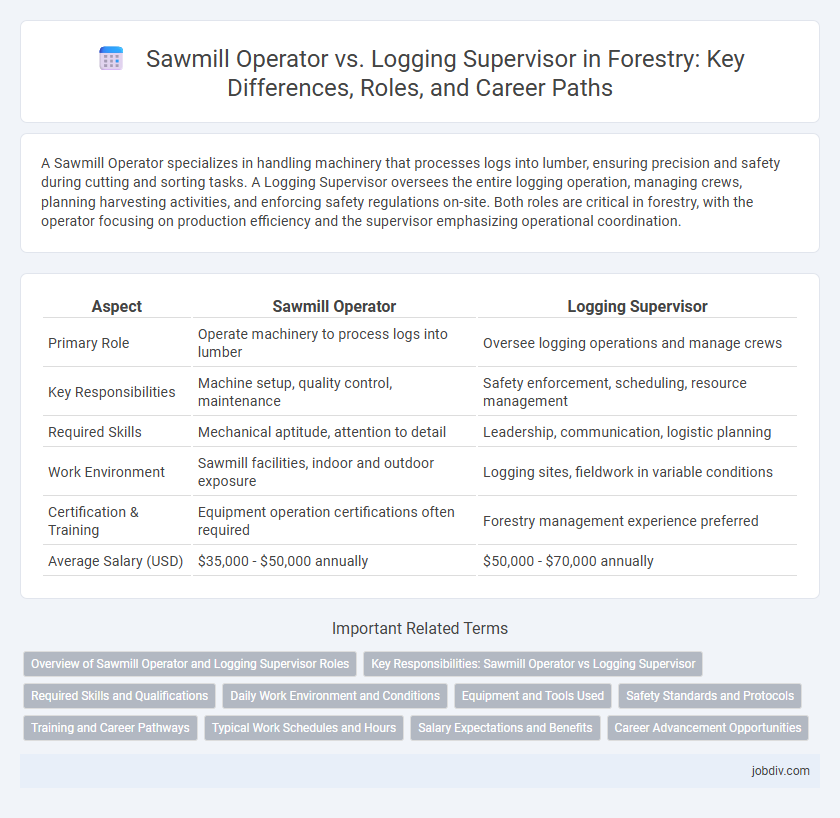

A Sawmill Operator specializes in handling machinery that processes logs into lumber, ensuring precision and safety during cutting and sorting tasks. A Logging Supervisor oversees the entire logging operation, managing crews, planning harvesting activities, and enforcing safety regulations on-site. Both roles are critical in forestry, with the operator focusing on production efficiency and the supervisor emphasizing operational coordination.

Table of Comparison

| Aspect | Sawmill Operator | Logging Supervisor |

|---|---|---|

| Primary Role | Operate machinery to process logs into lumber | Oversee logging operations and manage crews |

| Key Responsibilities | Machine setup, quality control, maintenance | Safety enforcement, scheduling, resource management |

| Required Skills | Mechanical aptitude, attention to detail | Leadership, communication, logistic planning |

| Work Environment | Sawmill facilities, indoor and outdoor exposure | Logging sites, fieldwork in variable conditions |

| Certification & Training | Equipment operation certifications often required | Forestry management experience preferred |

| Average Salary (USD) | $35,000 - $50,000 annually | $50,000 - $70,000 annually |

Overview of Sawmill Operator and Logging Supervisor Roles

Sawmill Operators manage the machinery that processes logs into lumber, focusing on equipment operation, maintenance, and product quality control within sawmills. Logging Supervisors coordinate timber harvesting operations, overseeing loggers, ensuring safety compliance, and optimizing workflow efficiency in forest environments. Both roles require knowledge of forestry practices and safety regulations, with operators specialized in mill machinery and supervisors in field management.

Key Responsibilities: Sawmill Operator vs Logging Supervisor

Sawmill Operators specialize in operating and maintaining sawmill equipment to process logs into lumber, ensuring machinery runs efficiently and meets production targets. Logging Supervisors manage logging crews, oversee harvesting operations, enforce safety regulations, and coordinate logistics to optimize timber extraction. Both roles require knowledge of forestry practices, but Sawmill Operators focus on precise milling processes while Logging Supervisors emphasize workforce management and environmental compliance.

Required Skills and Qualifications

Sawmill operators require technical proficiency in machine operation, mechanical maintenance, and safety protocols to efficiently process timber into lumber. Logging supervisors must possess strong leadership skills, knowledge of logging techniques, environmental regulations, and team coordination to manage harvesting operations safely and effectively. Both roles demand an understanding of forest products, but sawmill operators focus more on equipment handling, while logging supervisors emphasize operational planning and workforce management.

Daily Work Environment and Conditions

Sawmill operators work primarily indoors within controlled environments, managing machinery to process logs into lumber, often exposed to noise, dust, and varying temperatures. Logging supervisors operate outdoors at logging sites, overseeing tree harvesting activities in rugged terrain, facing weather extremes and physical hazards. Both roles require strict adherence to safety protocols but differ significantly in daily exposure to environmental conditions and physical demands.

Equipment and Tools Used

Sawmill operators primarily use industrial machinery such as circular saws, band saws, and automated edgers to process logs into lumber with precision and efficiency. Logging supervisors oversee the use of heavy equipment like feller bunchers, skidders, and forwarders to manage tree harvesting and transportation operations safely. Both roles require specialized tools, but sawmill operators focus on stationary processing equipment while logging supervisors coordinate mobile forestry machinery.

Safety Standards and Protocols

Sawmill operators and logging supervisors both enforce safety standards, but sawmill operators focus on maintaining machinery safety protocols to prevent operational hazards, while logging supervisors prioritize on-site safety measures, including personal protective equipment and fall prevention strategies. Logging supervisors conduct regular safety briefings and ensure compliance with OSHA regulations specific to logging environments, whereas sawmill operators adhere to safety procedures related to mechanical equipment handling and emergency shutdown processes. Both roles require comprehensive training in accident prevention and incident response to minimize workplace injuries in the forestry sector.

Training and Career Pathways

Sawmill operators typically require specialized training in machinery operation and safety protocols, often gained through vocational programs or on-the-job experience. Logging supervisors usually advance from hands-on logging roles, supplemented by leadership training and knowledge of forestry management to oversee operations effectively. Career pathways for sawmill operators focus on technical skill mastery, while logging supervisors progress toward management and strategic planning within the forestry sector.

Typical Work Schedules and Hours

Sawmill operators typically work in shifts that cover mornings, evenings, or nights, often totaling 40 to 50 hours per week to maintain continuous production. Logging supervisors usually have more variable schedules, often exceeding 50 hours per week, depending on field conditions and project deadlines. Both roles may require overtime and weekend work during peak logging or processing seasons.

Salary Expectations and Benefits

Sawmill Operators typically earn an average annual salary of $40,000 to $55,000, with benefits including health insurance, retirement plans, and paid time off. Logging Supervisors command higher salaries, ranging from $55,000 to $75,000 annually, reflecting their leadership responsibilities and often receive comprehensive benefits such as performance bonuses, safety incentives, and advanced healthcare coverage. Both roles may offer seasonal work opportunities and union membership benefits, but supervisors generally have greater job stability and career advancement potential.

Career Advancement Opportunities

Sawmill operators gain hands-on experience with wood processing machinery, making them valuable for roles such as production supervisors or quality control managers. Logging supervisors develop skills in workforce management, safety compliance, and operational logistics, positioning them for higher management or forestry consulting positions. Career advancement for sawmill operators often revolves around technical expertise, while logging supervisors typically progress through leadership and strategic planning roles.

Sawmill Operator vs Logging Supervisor Infographic

jobdiv.com

jobdiv.com