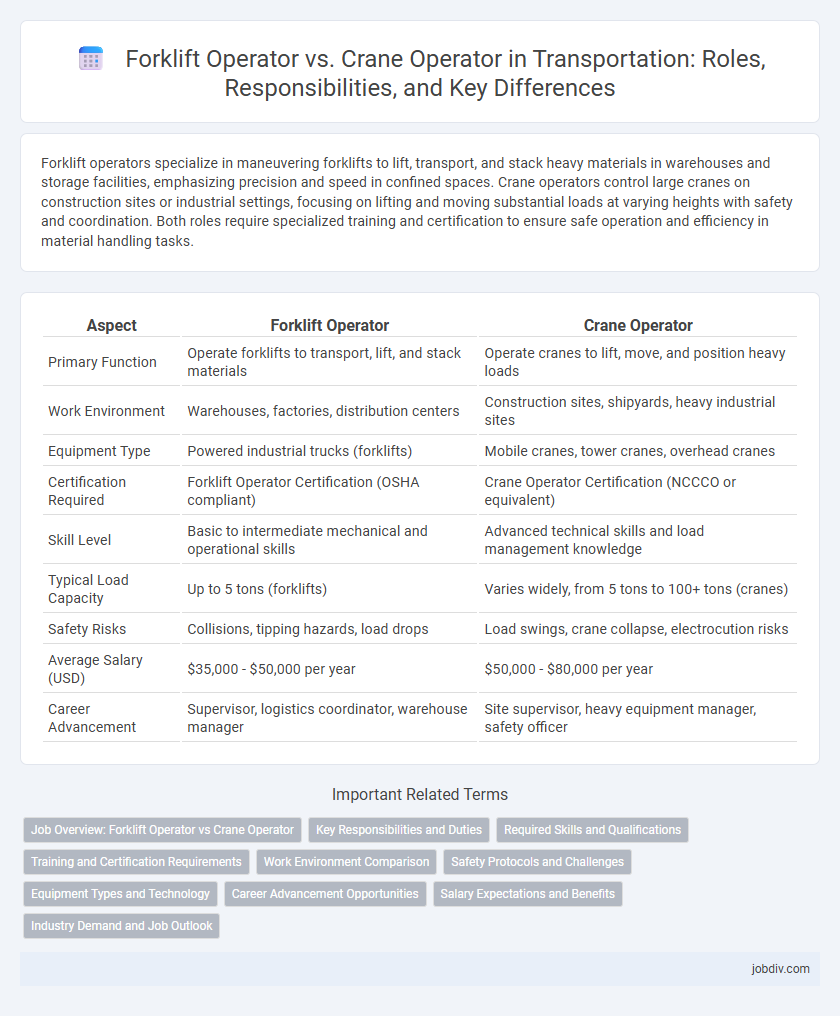

Forklift operators specialize in maneuvering forklifts to lift, transport, and stack heavy materials in warehouses and storage facilities, emphasizing precision and speed in confined spaces. Crane operators control large cranes on construction sites or industrial settings, focusing on lifting and moving substantial loads at varying heights with safety and coordination. Both roles require specialized training and certification to ensure safe operation and efficiency in material handling tasks.

Table of Comparison

| Aspect | Forklift Operator | Crane Operator |

|---|---|---|

| Primary Function | Operate forklifts to transport, lift, and stack materials | Operate cranes to lift, move, and position heavy loads |

| Work Environment | Warehouses, factories, distribution centers | Construction sites, shipyards, heavy industrial sites |

| Equipment Type | Powered industrial trucks (forklifts) | Mobile cranes, tower cranes, overhead cranes |

| Certification Required | Forklift Operator Certification (OSHA compliant) | Crane Operator Certification (NCCCO or equivalent) |

| Skill Level | Basic to intermediate mechanical and operational skills | Advanced technical skills and load management knowledge |

| Typical Load Capacity | Up to 5 tons (forklifts) | Varies widely, from 5 tons to 100+ tons (cranes) |

| Safety Risks | Collisions, tipping hazards, load drops | Load swings, crane collapse, electrocution risks |

| Average Salary (USD) | $35,000 - $50,000 per year | $50,000 - $80,000 per year |

| Career Advancement | Supervisor, logistics coordinator, warehouse manager | Site supervisor, heavy equipment manager, safety officer |

Job Overview: Forklift Operator vs Crane Operator

Forklift operators maneuver forklifts to lift, move, and stack materials in warehouses and construction sites, requiring skills in close-quarter navigation and load balancing. Crane operators control cranes to lift heavy materials at heights, demanding precision, spatial awareness, and heavy equipment certification. Both roles are critical in material handling but differ significantly in equipment complexity and operational environment.

Key Responsibilities and Duties

Forklift operators are responsible for moving, lifting, and stacking materials within warehouses, ensuring safe and efficient handling of pallets and goods using powered industrial trucks. Crane operators manage the operation of overhead or mobile cranes to lift, position, and move heavy materials at construction sites or loading docks, following strict safety protocols and precise load calculations. Both roles require adherence to safety standards, equipment inspections, and coordination with site supervisors to optimize workflow and prevent accidents.

Required Skills and Qualifications

Forklift operators must possess strong spatial awareness, manual dexterity, and certification in forklift operation, often requiring OSHA compliance and safety training. Crane operators need advanced mechanical knowledge, crane-specific licensing such as NCCCO certification, and the ability to interpret load charts and signals for precise lifting. Both roles demand attention to safety protocols, physical stamina, and experience with heavy machinery in dynamic industrial environments.

Training and Certification Requirements

Forklift operators require OSHA certification, involving hands-on training and written exams to ensure safe operation of powered industrial trucks. Crane operators must obtain certification from accredited organizations like NCCCO, which includes practical performance tests and knowledge-based assessments due to the high risk and complexity of crane operations. Training for crane operators is typically more extensive, covering load chart interpretation, signaling, and safety protocols, while forklift training emphasizes basic maneuvering and load handling.

Work Environment Comparison

Forklift operators typically work in indoor warehouses, distribution centers, and manufacturing facilities, navigating tight spaces and handling pallets or goods on flat surfaces. Crane operators often perform duties on construction sites, shipyards, or heavy industrial areas, managing heavy loads at greater heights and varying outdoor weather conditions. The physical demands and safety risks differ significantly, with crane operators facing exposure to environmental elements and complex rigging tasks, whereas forklift operators encounter confined spaces and frequent material movement.

Safety Protocols and Challenges

Forklift operators must adhere to strict safety protocols such as maintaining clear visibility, performing pre-operation equipment checks, and wearing appropriate personal protective equipment to prevent tip-overs and collisions in confined warehouse spaces. Crane operators face challenges including managing heavy loads at significant heights, ensuring stable ground conditions, and following precise signaling communication to avoid structural failures and accidents. Both roles require specialized training, constant vigilance, and adherence to Occupational Safety and Health Administration (OSHA) regulations to mitigate risks and ensure workplace safety.

Equipment Types and Technology

Forklift operators primarily use counterbalance forklifts, reach trucks, and pallet jacks equipped with hydraulic lifting mechanisms and electronic controls for precise material handling in warehouses. Crane operators manage tower cranes, mobile cranes, and overhead cranes featuring advanced load moment indicators, remote control systems, and telematics for heavy lifting and construction projects. Both roles require specialized training on equipment safety and technology integration to optimize operational efficiency.

Career Advancement Opportunities

Forklift operators have clear career advancement paths including roles like warehouse supervisor, logistics manager, or safety coordinator, leveraging their expertise in material handling and warehouse operations. Crane operators can progress to specialized positions such as rigging supervisor, heavy equipment operator trainer, or construction site manager, capitalizing on their skills in operating complex lifting machinery on construction and industrial sites. Both careers offer certification-based advancement opportunities that increase earning potential and job responsibilities within the transportation and logistics sectors.

Salary Expectations and Benefits

Forklift operators typically earn an average salary ranging from $35,000 to $50,000 annually, while crane operators can expect higher compensation, often between $50,000 and $75,000 per year due to the specialized skill set required. Benefits for both roles frequently include health insurance, retirement plans, and paid time off, with crane operators sometimes receiving additional hazard pay or certification bonuses. Salary prospects for crane operators improve with experience and licensing, highlighting the financial advantage of investing in advanced training.

Industry Demand and Job Outlook

The demand for forklift operators remains strong due to the growth of warehousing and distribution centers in logistics and manufacturing industries, with the Bureau of Labor Statistics projecting a 5% employment increase through 2031. Crane operators are experiencing steady job growth, approximately 7%, driven by ongoing construction projects and infrastructure development, particularly in urban areas. Both roles require specialized certifications, but crane operators generally command higher wages due to the complexity and risk involved in heavy lifting tasks on construction sites.

Forklift Operator vs Crane Operator Infographic

jobdiv.com

jobdiv.com