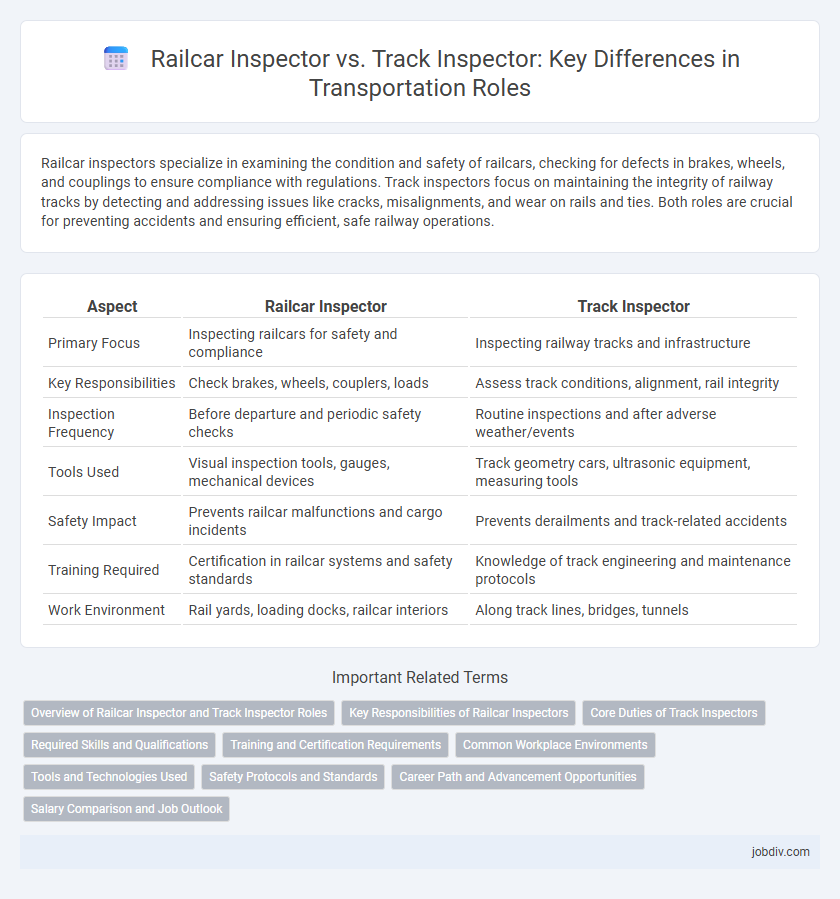

Railcar inspectors specialize in examining the condition and safety of railcars, checking for defects in brakes, wheels, and couplings to ensure compliance with regulations. Track inspectors focus on maintaining the integrity of railway tracks by detecting and addressing issues like cracks, misalignments, and wear on rails and ties. Both roles are crucial for preventing accidents and ensuring efficient, safe railway operations.

Table of Comparison

| Aspect | Railcar Inspector | Track Inspector |

|---|---|---|

| Primary Focus | Inspecting railcars for safety and compliance | Inspecting railway tracks and infrastructure |

| Key Responsibilities | Check brakes, wheels, couplers, loads | Assess track conditions, alignment, rail integrity |

| Inspection Frequency | Before departure and periodic safety checks | Routine inspections and after adverse weather/events |

| Tools Used | Visual inspection tools, gauges, mechanical devices | Track geometry cars, ultrasonic equipment, measuring tools |

| Safety Impact | Prevents railcar malfunctions and cargo incidents | Prevents derailments and track-related accidents |

| Training Required | Certification in railcar systems and safety standards | Knowledge of track engineering and maintenance protocols |

| Work Environment | Rail yards, loading docks, railcar interiors | Along track lines, bridges, tunnels |

Overview of Railcar Inspector and Track Inspector Roles

Railcar inspectors specialize in examining freight and passenger railcars to ensure structural integrity, safety compliance, and operational readiness, identifying defects such as brake issues, wheel wear, and structural damage. Track inspectors focus on monitoring the condition of railway tracks, including rails, ties, and ballast, detecting faults like cracks, misalignments, and erosion to maintain track stability and safety. Both roles are critical for preventing accidents and ensuring efficient rail transportation through rigorous inspection protocols.

Key Responsibilities of Railcar Inspectors

Railcar Inspectors primarily focus on examining freight and passenger railcars for mechanical defects, ensuring compliance with safety standards and regulatory requirements to prevent accidents and service disruptions. They perform detailed inspections of wheels, brakes, couplers, and structural components, identifying wear and damage that could compromise railcar integrity. Track Inspectors, by contrast, concentrate on the condition of the railway tracks, assessing rail alignment, ties, and ballast to maintain safe and efficient train operations.

Core Duties of Track Inspectors

Track inspectors primarily focus on examining railroad tracks for defects, ensuring the alignment, stability, and safety of rails, ties, and ballast. They use specialized equipment to detect cracks, wear, and other structural issues that could lead to derailments or operational hazards. Their core duties include routine inspections, identifying maintenance needs, and reporting track conditions to prevent accidents and maintain regulatory compliance.

Required Skills and Qualifications

Railcar inspectors require expertise in mechanical systems, knowledge of railroad safety standards, and skills in detecting defects in wheelsets, brakes, and couplers to ensure operational safety. Track inspectors must have a strong understanding of track geometry, rail integrity, and ballast conditions, along with proficiency in using specialized inspection tools and interpreting technical blueprints. Both roles demand attention to detail, adherence to regulatory compliance, and the ability to perform thorough visual and tactile inspections under varying environmental conditions.

Training and Certification Requirements

Railcar inspectors require specialized training in mechanical systems, brake functionality, and safety compliance, often obtaining certification through organizations like the Association of American Railroads (AAR). Track inspectors undergo rigorous training focused on track geometry, rail integrity, and signal systems, with certifications provided by bodies such as the Federal Railroad Administration (FRA). Both roles demand continuous education to meet evolving safety standards and regulatory mandates within the rail industry.

Common Workplace Environments

Railcar Inspectors and Track Inspectors both operate in demanding environments under varying weather conditions, often exposed to outdoor elements such as rain, snow, and extreme temperatures. Railcar Inspectors typically work in rail yards, depots, and maintenance facilities where they examine railcars for safety and compliance. Track Inspectors perform inspections along railway tracks, bridges, and tunnels, requiring frequent fieldwork and physical activity to identify structural issues and ensure railway integrity.

Tools and Technologies Used

Railcar inspectors utilize ultrasonic flaw detectors, wheel profile gauges, and portable hardness testers to evaluate railcar components for structural integrity, ensuring safety and compliance. Track inspectors rely heavily on track geometry measurement systems, ground-penetrating radar, and automated track monitoring drones to assess rail alignment, ballast conditions, and detect subsurface defects. Both roles integrate advanced software platforms for data analysis, but railcar inspection tools emphasize vehicle-specific diagnostics while track inspection technologies focus on infrastructure monitoring.

Safety Protocols and Standards

Railcar inspectors rigorously assess the structural integrity, brake systems, and coupling devices of railcars to ensure compliance with safety protocols such as the Association of American Railroads (AAR) standards. Track inspectors focus on the evaluation of rail alignment, track geometry, and railroad ties, adhering to Federal Railroad Administration (FRA) regulations to prevent derailments and maintain smooth train operations. Both roles implement strict safety measures, but railcar inspectors emphasize vehicle condition, whereas track inspectors concentrate on track infrastructure safety.

Career Path and Advancement Opportunities

Railcar Inspectors specialize in examining freight and passenger cars for safety, identifying defects to ensure operational reliability, often advancing into supervisory roles or specialized maintenance management. Track Inspectors focus on maintaining and inspecting railway tracks, detecting issues such as alignment problems and wear, with career growth leading to senior engineering positions or infrastructure project management. Both careers offer pathways into safety regulation enforcement, quality assurance, and technical training roles within the rail transportation industry.

Salary Comparison and Job Outlook

Railcar inspectors typically earn an average salary ranging from $45,000 to $65,000 annually, reflecting their specialized role in assessing the safety and functionality of freight and passenger railcars. Track inspectors, responsible for monitoring and maintaining rail tracks, often have a slightly higher salary range, between $50,000 and $70,000 per year, due to the physical demands and safety-critical nature of their work. Employment growth for both positions is projected to remain steady, driven by ongoing infrastructure investments and regulatory safety requirements within the rail transportation industry.

Railcar Inspector vs Track Inspector Infographic

jobdiv.com

jobdiv.com