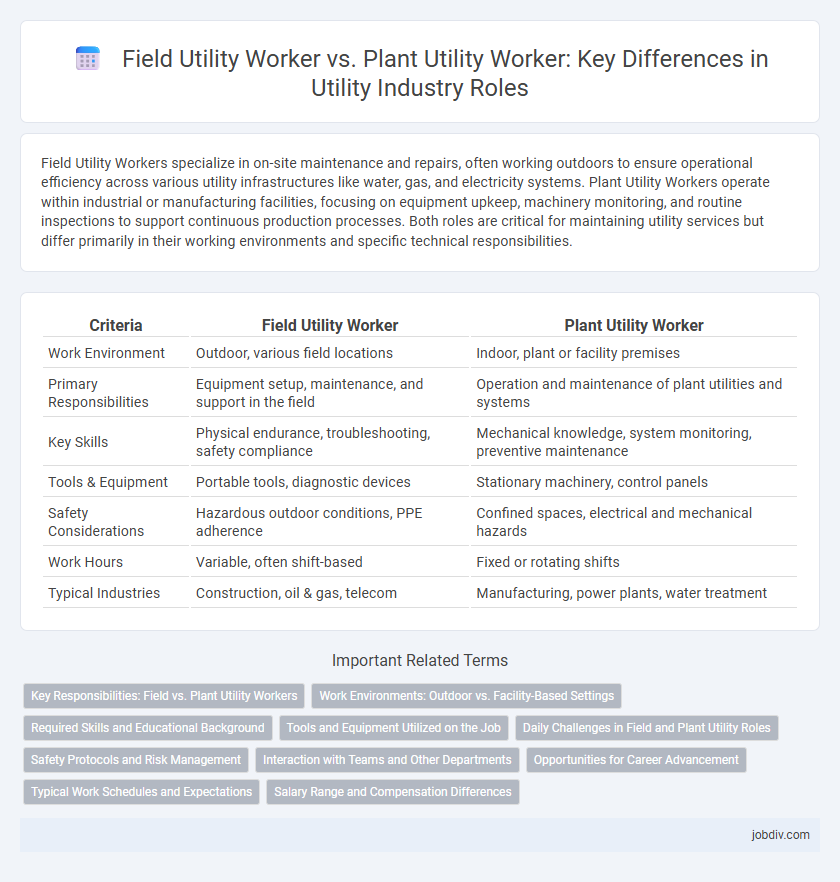

Field Utility Workers specialize in on-site maintenance and repairs, often working outdoors to ensure operational efficiency across various utility infrastructures like water, gas, and electricity systems. Plant Utility Workers operate within industrial or manufacturing facilities, focusing on equipment upkeep, machinery monitoring, and routine inspections to support continuous production processes. Both roles are critical for maintaining utility services but differ primarily in their working environments and specific technical responsibilities.

Table of Comparison

| Criteria | Field Utility Worker | Plant Utility Worker |

|---|---|---|

| Work Environment | Outdoor, various field locations | Indoor, plant or facility premises |

| Primary Responsibilities | Equipment setup, maintenance, and support in the field | Operation and maintenance of plant utilities and systems |

| Key Skills | Physical endurance, troubleshooting, safety compliance | Mechanical knowledge, system monitoring, preventive maintenance |

| Tools & Equipment | Portable tools, diagnostic devices | Stationary machinery, control panels |

| Safety Considerations | Hazardous outdoor conditions, PPE adherence | Confined spaces, electrical and mechanical hazards |

| Work Hours | Variable, often shift-based | Fixed or rotating shifts |

| Typical Industries | Construction, oil & gas, telecom | Manufacturing, power plants, water treatment |

Key Responsibilities: Field vs. Plant Utility Workers

Field Utility Workers primarily handle maintenance, installation, and repair of utility infrastructure such as power lines, water pipelines, and communication cables across outdoor environments. Plant Utility Workers focus on operating, monitoring, and maintaining equipment and systems within utility plants, ensuring optimal performance of boilers, pumps, and control systems. While Field Utility Workers emphasize on-site physical tasks and troubleshooting in diverse settings, Plant Utility Workers concentrate on system stability, safety protocols, and machinery upkeep inside controlled facility environments.

Work Environments: Outdoor vs. Facility-Based Settings

Field Utility Workers operate primarily in outdoor environments, managing infrastructure such as power lines, water systems, and telecommunications. Plant Utility Workers perform their duties within facility-based settings, maintaining equipment and systems vital to plant operations. The outdoor nature of fieldwork demands adaptability to weather and terrain, while plant-based roles require adherence to safety protocols in controlled industrial environments.

Required Skills and Educational Background

Field Utility Workers require strong problem-solving skills and physical stamina to handle outdoor equipment maintenance and repairs, often necessitating a high school diploma or equivalent. Plant Utility Workers need technical proficiency in operating industrial machinery and monitoring plant systems, typically supported by specialized training or vocational education in industrial operations. Both roles demand safety awareness and teamwork but differ primarily in their environment and specific technical competencies.

Tools and Equipment Utilized on the Job

Field Utility Workers primarily utilize portable tools such as pipe wrenches, voltage testers, and excavation equipment to maintain and repair outdoor utility infrastructure. Plant Utility Workers operate stationary machinery and specialized equipment, including boilers, pumps, and control panels, to ensure continuous operation within industrial facilities. Both roles require proficiency in safety gear like protective gloves, helmets, and gas detectors tailored to their specific environments.

Daily Challenges in Field and Plant Utility Roles

Field Utility Workers confront daily challenges such as unpredictable weather conditions, uneven terrain, and remote locations that demand physical endurance and adaptability. Plant Utility Workers face rigorous safety protocols, complex machinery maintenance, and constant monitoring of equipment performance to ensure operational efficiency. Both roles require specialized skills, but field positions emphasize mobility and environmental resilience, while plant roles prioritize technical proficiency and equipment oversight.

Safety Protocols and Risk Management

Field Utility Workers primarily operate in outdoor and variable environments, requiring strict adherence to safety protocols such as personal protective equipment (PPE) usage, hazard communication, and emergency response plans tailored to unpredictable conditions. Plant Utility Workers focus on maintaining and operating equipment within controlled industrial settings, where risk management involves monitoring machinery safety systems, following lockout/tagout procedures, and performing regular safety audits to prevent operational hazards. Both roles necessitate comprehensive training in workplace safety standards and proactive risk assessment to minimize accidents and ensure regulatory compliance.

Interaction with Teams and Other Departments

Field Utility Workers coordinate closely with maintenance crews and operations teams on-site to troubleshoot equipment issues and ensure continuous field operations. Plant Utility Workers interact extensively with production, safety, and engineering departments to maintain optimal plant efficiency and compliance with safety regulations. Both roles require effective communication and teamwork to support overall utility system reliability and performance.

Opportunities for Career Advancement

Field Utility Workers often gain hands-on experience in diverse outdoor environments, positioning them for advancement into specialized roles such as Linesperson or Equipment Operator. Plant Utility Workers benefit from consistent exposure to industrial systems and machinery, facilitating career growth toward Technician or Maintenance Supervisor positions. Both roles offer pathways to leadership, but career advancement in the plant environment typically involves technical certification and expertise in system operations.

Typical Work Schedules and Expectations

Field Utility Workers often follow variable work schedules that include outdoor conditions and on-site tasks, usually involving early mornings or extended shifts to address urgent repairs and maintenance. Plant Utility Workers typically maintain more consistent hours in a controlled environment, working standard daytime or rotating shifts focused on plant operations and equipment monitoring. Both roles demand flexibility and readiness for overtime during peak operational periods or emergencies.

Salary Range and Compensation Differences

Field Utility Workers typically earn between $35,000 and $50,000 annually, with wages influenced by location and job-specific skills. Plant Utility Workers generally receive a salary range from $40,000 to $55,000, reflecting the more controlled environment and technical demands of plant operations. Compensation packages for Plant Utility Workers often include additional benefits like overtime pay and hazard allowances, contributing to their comparatively higher total earnings.

Field Utility Worker vs Plant Utility Worker Infographic

jobdiv.com

jobdiv.com