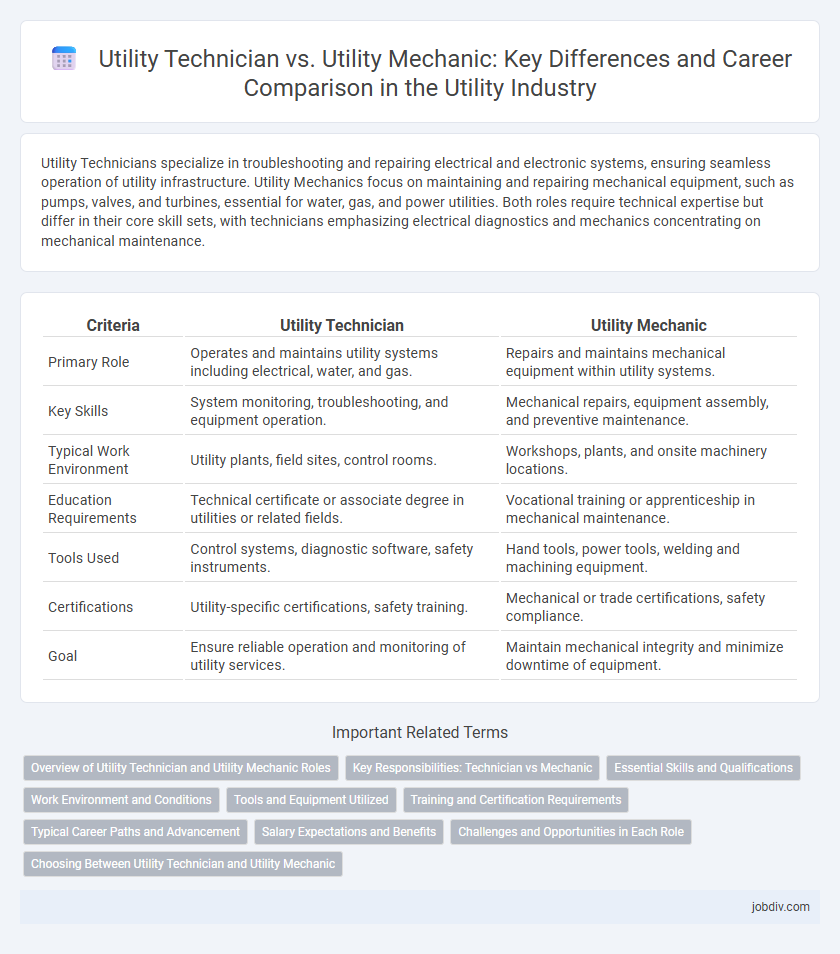

Utility Technicians specialize in troubleshooting and repairing electrical and electronic systems, ensuring seamless operation of utility infrastructure. Utility Mechanics focus on maintaining and repairing mechanical equipment, such as pumps, valves, and turbines, essential for water, gas, and power utilities. Both roles require technical expertise but differ in their core skill sets, with technicians emphasizing electrical diagnostics and mechanics concentrating on mechanical maintenance.

Table of Comparison

| Criteria | Utility Technician | Utility Mechanic |

|---|---|---|

| Primary Role | Operates and maintains utility systems including electrical, water, and gas. | Repairs and maintains mechanical equipment within utility systems. |

| Key Skills | System monitoring, troubleshooting, and equipment operation. | Mechanical repairs, equipment assembly, and preventive maintenance. |

| Typical Work Environment | Utility plants, field sites, control rooms. | Workshops, plants, and onsite machinery locations. |

| Education Requirements | Technical certificate or associate degree in utilities or related fields. | Vocational training or apprenticeship in mechanical maintenance. |

| Tools Used | Control systems, diagnostic software, safety instruments. | Hand tools, power tools, welding and machining equipment. |

| Certifications | Utility-specific certifications, safety training. | Mechanical or trade certifications, safety compliance. |

| Goal | Ensure reliable operation and monitoring of utility services. | Maintain mechanical integrity and minimize downtime of equipment. |

Overview of Utility Technician and Utility Mechanic Roles

Utility Technicians handle installation, maintenance, and repair of utility systems such as electrical, water, and gas infrastructure, utilizing diagnostic tools and technical expertise. Utility Mechanics specialize in maintaining and repairing mechanical equipment within utility facilities, focusing on engines, pumps, and heavy machinery to ensure operational efficiency. Both roles require technical skills but differ in their emphasis on system types and mechanical versus electrical maintenance tasks.

Key Responsibilities: Technician vs Mechanic

Utility Technicians are responsible for monitoring, troubleshooting, and maintaining electrical, water, or gas systems using diagnostic tools and software to ensure continuous utility service. Utility Mechanics focus on repairing and maintaining mechanical equipment such as pumps, valves, and pipelines, performing hands-on tasks like welding, part replacement, and system overhauls. Both roles require specialized skills, but Technicians emphasize system analysis and electronic diagnostics, while Mechanics concentrate on physical hardware repair and mechanical system integrity.

Essential Skills and Qualifications

Utility Technicians require strong troubleshooting abilities, electrical knowledge, and proficiency with diagnostic tools to maintain and repair utility systems efficiently. Utility Mechanics must possess mechanical aptitude, experience with heavy machinery, and skills in welding and metal fabrication to ensure the structural and operational integrity of utility equipment. Both roles demand physical stamina, safety awareness, and adherence to regulatory standards, but their technical skill sets differ based on the specialized focus of electrical systems versus mechanical maintenance.

Work Environment and Conditions

Utility Technicians typically work outdoors in varied weather conditions, often handling electrical or water systems maintenance, requiring physical agility and safety precautions due to exposure to live equipment. Utility Mechanics usually operate in more controlled environments such as utility plant facilities or vehicle repair shops, focusing on mechanical repairs and equipment upkeep, which demands technical expertise and adherence to safety protocols in confined or hazardous spaces. Both roles involve shift work and emergency response duties, emphasizing readiness in dynamic and potentially hazardous work environments.

Tools and Equipment Utilized

Utility Technicians primarily utilize diagnostic tools, meters, and handheld devices to monitor and maintain utility systems, ensuring accurate data collection and system performance. Utility Mechanics focus on heavy machinery, hand tools, and specialized mechanical equipment to repair and maintain infrastructure components such as pumps, valves, and motors. Both roles require proficiency with specific tools, but Utility Mechanics handle more physical, mechanical equipment while Utility Technicians rely heavily on electronic and diagnostic instruments.

Training and Certification Requirements

Utility Technicians typically require specialized vocational training or an associate degree in utility systems, with certifications such as OSHA safety training and confined space entry. Utility Mechanics often need more extensive hands-on mechanical training and may hold certifications in equipment maintenance, welding, or hydraulics, reflecting their focus on repairing and maintaining utility infrastructure. Both roles prioritize safety certifications and technical skills, but Mechanics demand deeper mechanical expertise and specific trade certifications.

Typical Career Paths and Advancement

Utility Technicians often begin their careers with entry-level roles in system monitoring and maintenance, advancing through specialized certifications in electrical or water systems to supervisory positions. Utility Mechanics typically start with hands-on mechanical repairs and equipment installation, progressing by gaining expertise in hydraulics, pneumatics, and system diagnostics, leading to senior mechanic or technical management roles. Both paths offer advancement opportunities into project management, safety coordination, and utility operations leadership depending on skills and continued education.

Salary Expectations and Benefits

Utility Technicians typically earn an average salary ranging from $45,000 to $65,000 annually, with benefits including health insurance, retirement plans, and paid time off, reflecting their role in equipment monitoring and troubleshooting. Utility Mechanics generally command higher salaries between $55,000 and $75,000 per year, owing to their specialized skills in repairing and maintaining heavy machinery, alongside comprehensive benefits such as overtime pay, health coverage, and apprenticeship opportunities. Both positions offer job stability in the utility sector, but Utility Mechanics often receive additional compensation due to the technical demands of their duties.

Challenges and Opportunities in Each Role

Utility Technicians face challenges in troubleshooting complex electrical and mechanical systems, requiring rapid problem-solving skills and adaptability to evolving technologies. Utility Mechanics encounter opportunities to enhance infrastructure reliability through specialized maintenance and repair of heavy machinery, often benefiting from hands-on experience and technical certifications. Both roles demand rigorous safety adherence, but Technicians often engage more with diagnostic tools, while Mechanics focus on physical system integrity, creating distinct yet complementary career pathways.

Choosing Between Utility Technician and Utility Mechanic

Choosing between a Utility Technician and a Utility Mechanic depends on the specific skills and tasks required; Utility Technicians typically handle system diagnostics, installations, and technical troubleshooting, while Utility Mechanics focus on the maintenance, repair, and assembly of mechanical equipment. Both roles are critical in utilities such as water, gas, and electric services, but selecting the right position hinges on whether the job prioritizes electronic systems expertise or mechanical repair skills. Employers often seek Utility Technicians for advanced technical problem-solving and Utility Mechanics for hands-on mechanical maintenance and machinery upkeep.

Utility Technician vs Utility Mechanic Infographic

jobdiv.com

jobdiv.com