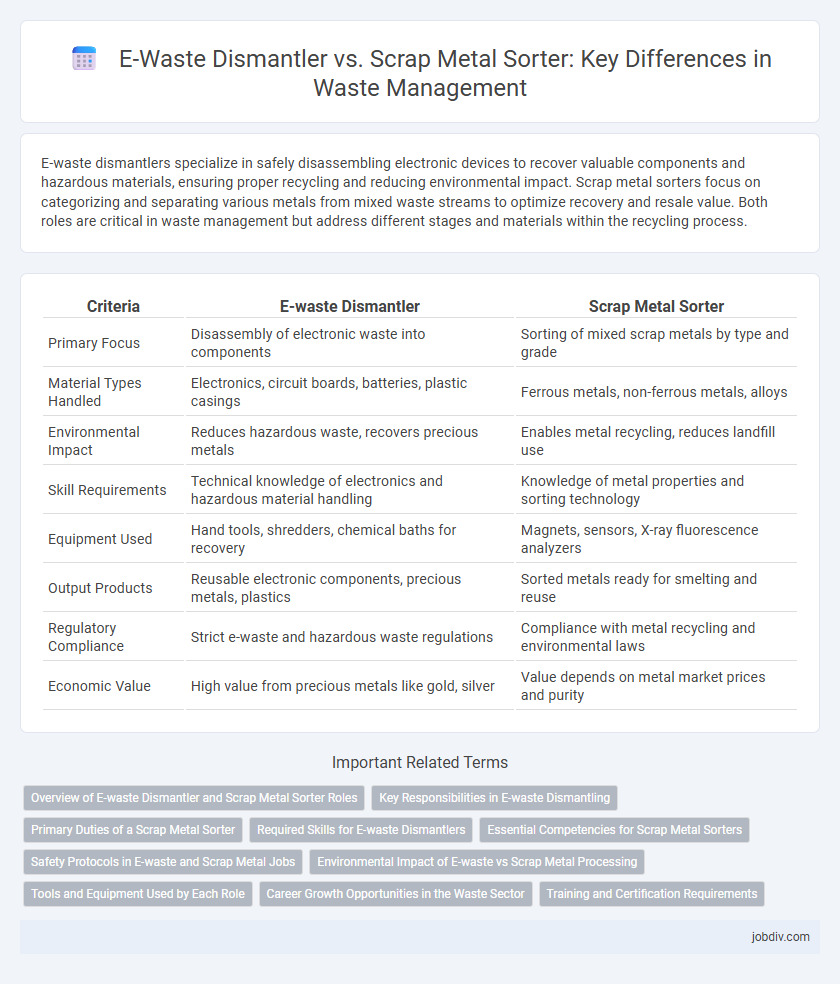

E-waste dismantlers specialize in safely disassembling electronic devices to recover valuable components and hazardous materials, ensuring proper recycling and reducing environmental impact. Scrap metal sorters focus on categorizing and separating various metals from mixed waste streams to optimize recovery and resale value. Both roles are critical in waste management but address different stages and materials within the recycling process.

Table of Comparison

| Criteria | E-waste Dismantler | Scrap Metal Sorter |

|---|---|---|

| Primary Focus | Disassembly of electronic waste into components | Sorting of mixed scrap metals by type and grade |

| Material Types Handled | Electronics, circuit boards, batteries, plastic casings | Ferrous metals, non-ferrous metals, alloys |

| Environmental Impact | Reduces hazardous waste, recovers precious metals | Enables metal recycling, reduces landfill use |

| Skill Requirements | Technical knowledge of electronics and hazardous material handling | Knowledge of metal properties and sorting technology |

| Equipment Used | Hand tools, shredders, chemical baths for recovery | Magnets, sensors, X-ray fluorescence analyzers |

| Output Products | Reusable electronic components, precious metals, plastics | Sorted metals ready for smelting and reuse |

| Regulatory Compliance | Strict e-waste and hazardous waste regulations | Compliance with metal recycling and environmental laws |

| Economic Value | High value from precious metals like gold, silver | Value depends on metal market prices and purity |

Overview of E-waste Dismantler and Scrap Metal Sorter Roles

E-waste dismantlers specialize in carefully disassembling electronic devices to recover valuable components such as circuit boards, batteries, and precious metals, minimizing environmental harm and promoting recycling efficiency. Scrap metal sorters focus on categorizing and separating metals like copper, aluminum, and steel from mixed waste streams, ensuring metals are properly processed for reuse in manufacturing. Both roles are critical in the waste management sector, enhancing material recovery and reducing landfill impact through specialized handling of electronic and metal waste.

Key Responsibilities in E-waste Dismantling

E-waste dismantlers specialize in safely disassembling electronic devices to separate hazardous components from valuable materials such as circuit boards, batteries, and plastics, ensuring compliance with environmental regulations. Their key responsibilities include identifying and extracting reusable parts, managing toxic substances like lead and mercury, and minimizing environmental contamination during the dismantling process. In contrast, scrap metal sorters primarily focus on categorizing and segregating metals by type and grade, without the intricate separation required in e-waste recycling.

Primary Duties of a Scrap Metal Sorter

A scrap metal sorter primarily identifies, categorizes, and separates various types of metals such as ferrous and non-ferrous materials to ensure efficient recycling and resale. This role involves inspecting incoming waste, using magnets and sensors, and removing contaminants to maintain material purity. Proper sorting enhances the value of scrap metal and supports sustainable waste management practices by reducing landfill accumulation.

Required Skills for E-waste Dismantlers

E-waste dismantlers require specialized knowledge in electronics and safe handling of hazardous materials to effectively separate valuable components from discarded devices. Proficiency in using precision tools, understanding circuit boards, and adherence to environmental regulations are critical to minimize health risks and maximize resource recovery. Unlike scrap metal sorters who focus primarily on identifying and sorting metals, e-waste dismantlers must also recognize and extract non-metal elements such as plastics, glass, and batteries.

Essential Competencies for Scrap Metal Sorters

Scrap metal sorters require essential competencies in material identification, magnetic separation techniques, and knowledge of metal grades to efficiently categorize and process recyclable metals. Proficiency in operating sorting machinery and understanding environmental regulations ensures proper handling and maximizes recovery rates. Strong attention to detail and safety awareness are critical for minimizing contamination and workplace hazards during sorting operations.

Safety Protocols in E-waste and Scrap Metal Jobs

E-waste dismantlers follow strict safety protocols including the use of personal protective equipment (PPE) such as gloves, masks, and eye protection to prevent exposure to hazardous substances like lead, mercury, and cadmium. Scrap metal sorters prioritize safety measures by implementing ergonomic handling techniques, wearing steel-toed boots, and using machinery guards to reduce the risk of physical injuries and metal contaminants. Both roles require adherence to proper ventilation standards and thorough training to minimize health hazards and environmental impact during the recycling process.

Environmental Impact of E-waste vs Scrap Metal Processing

E-waste dismantlers specialize in carefully separating hazardous components such as batteries, circuit boards, and plastics, significantly reducing the risk of toxic substance release into the environment compared to traditional scrap metal sorting. Scrap metal sorters primarily handle ferrous and non-ferrous metals, often overlooking the proper disposal of hazardous electronic materials, which leads to increased soil and water contamination. Proper e-waste dismantling methods enhance resource recovery efficiency while minimizing heavy metal pollution, making it a more environmentally responsible choice than conventional scrap metal processing.

Tools and Equipment Used by Each Role

E-waste dismantlers rely on specialized tools such as screwdrivers, pliers, wire cutters, and anti-static gloves to safely deassemble electronic devices and extract valuable components like circuit boards and batteries. Scrap metal sorters utilize magnetic separators, metal detectors, and conveyor belts to efficiently identify and separate ferrous and non-ferrous metals from mixed waste streams. Both roles require protective gear and precision instruments tailored to their specific processes, ensuring effective material recovery and environmental compliance.

Career Growth Opportunities in the Waste Sector

E-waste dismantlers possess specialized skills in handling and separating electronic components, leading to accelerated career growth in tech-focused recycling roles. Scrap metal sorters, skilled in categorizing and processing various metal types, benefit from steady demand and opportunities to advance into supervisory and operational management positions. Both roles offer distinct pathways in the waste sector, with e-waste dismantling aligning with the expanding electronic recycling industry and scrap metal sorting supporting the broader metal recovery market.

Training and Certification Requirements

E-waste dismantlers require specialized training in hazardous material handling, circuit board extraction, and data security protocols to safely manage electronic components and comply with environmental regulations. Scrap metal sorters focus on identifying and segregating various metals based on composition, needing certifications in metal recycling safety and material recovery techniques. Both roles demand adherence to Occupational Safety and Health Administration (OSHA) standards, but e-waste dismantlers often hold additional certifications such as R2 (Responsible Recycling) or e-Stewards to ensure responsible electronic waste processing.

E-waste Dismantler vs Scrap Metal Sorter Infographic

jobdiv.com

jobdiv.com