Skip lorry drivers operate large vehicles designed to transport bulky waste containers, efficiently loading and unloading skips at various sites. Rear loader drivers, on the other hand, specialize in waste collection vehicles equipped with rear-loading mechanisms, streamlining the collection of household and commercial refuse. Both roles are crucial for effective waste management, demanding skilled handling of specialized equipment to ensure timely and safe waste transport.

Table of Comparison

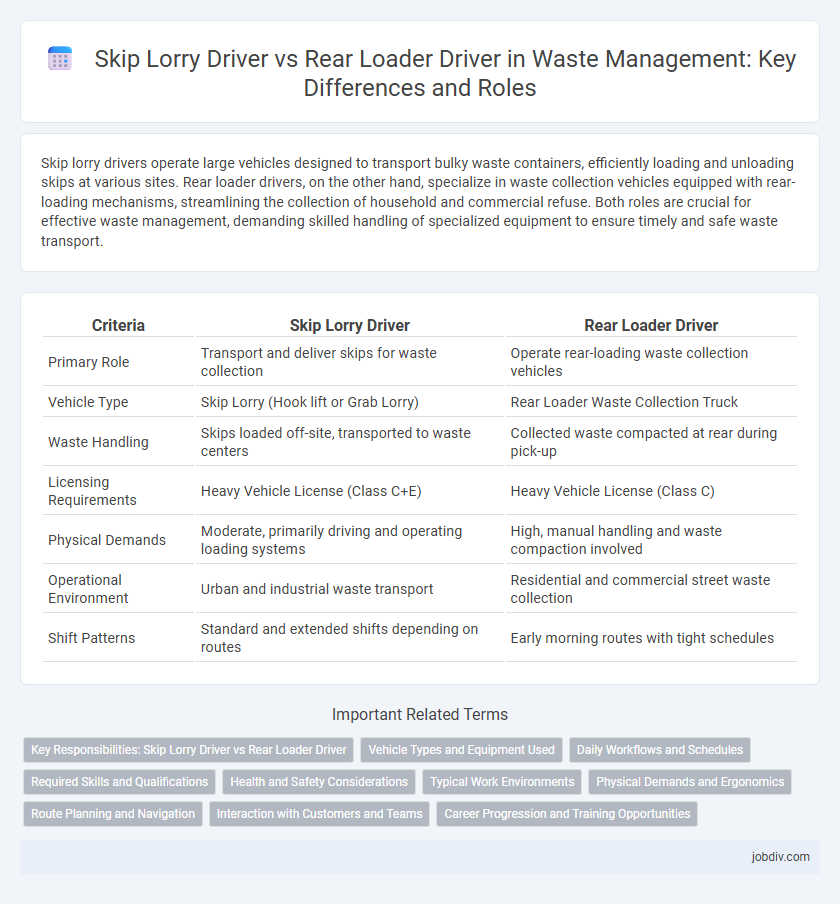

| Criteria | Skip Lorry Driver | Rear Loader Driver |

|---|---|---|

| Primary Role | Transport and deliver skips for waste collection | Operate rear-loading waste collection vehicles |

| Vehicle Type | Skip Lorry (Hook lift or Grab Lorry) | Rear Loader Waste Collection Truck |

| Waste Handling | Skips loaded off-site, transported to waste centers | Collected waste compacted at rear during pick-up |

| Licensing Requirements | Heavy Vehicle License (Class C+E) | Heavy Vehicle License (Class C) |

| Physical Demands | Moderate, primarily driving and operating loading systems | High, manual handling and waste compaction involved |

| Operational Environment | Urban and industrial waste transport | Residential and commercial street waste collection |

| Shift Patterns | Standard and extended shifts depending on routes | Early morning routes with tight schedules |

Key Responsibilities: Skip Lorry Driver vs Rear Loader Driver

Skip Lorry Drivers are responsible for transporting large waste containers to and from collection sites, ensuring secure loading and unloading of skips using hydraulic systems. Rear Loader Drivers specialize in operating rear-loading garbage trucks, managing the compaction of general waste, and overseeing the safe collection of residential or commercial refuse. Both roles require precise vehicle maneuvering, adherence to safety protocols, and efficient waste handling to optimize collection routes and maintain environmental standards.

Vehicle Types and Equipment Used

Skip lorry drivers operate large trucks equipped with hydraulic arms designed to lift and transport open or closed skips, commonly used in construction and waste collection for bulky materials. Rear loader drivers handle specialized vehicles featuring a rear compaction mechanism that compresses waste inside the vehicle, ideal for residential and commercial refuse collection with limited space. The distinct vehicle types and equipment directly impact efficiency, safety, and waste management practices in various collection environments.

Daily Workflows and Schedules

Skip lorry drivers typically follow fixed collection routes, focusing on transporting large volumes of skip containers from construction and industrial sites to waste processing facilities. Rear loader drivers operate on more flexible schedules, handling residential and commercial waste collection with frequent stops for loading bins manually or mechanically at the rear of the truck. Both roles require strict adherence to waste disposal regulations and efficient route management to optimize daily workflows and minimize downtime.

Required Skills and Qualifications

Skip lorry drivers must possess a valid heavy goods vehicle (HGV) license and demonstrate proficiency in vehicle maneuvering and safe loading techniques to handle large skips efficiently. Rear loader drivers require skills in operating hydraulic lift systems and compacting waste while adhering to safety protocols, along with a valid HGV license or relevant commercial vehicle qualifications. Both roles demand strong knowledge of waste management regulations, physical fitness, and excellent time management to ensure timely waste collection and disposal.

Health and Safety Considerations

Skip lorry drivers face significant health risks due to long hours of vehicle operation and manual handling of heavy skip loads, increasing musculoskeletal injury potential. Rear loader drivers are exposed to repetitive lifting, compacting mechanisms, and hazardous waste materials, raising the likelihood of cuts, crush injuries, and respiratory issues. Strict adherence to personal protective equipment (PPE), ergonomic protocols, and vehicle maintenance is essential for minimizing workplace accidents and promoting driver safety in waste collection operations.

Typical Work Environments

Skip lorry drivers typically operate in construction sites, industrial areas, and urban zones where large volumes of bulky waste require transportation to disposal or recycling facilities. Rear loader drivers primarily work in residential neighborhoods and commercial districts, collecting curbside waste using specialized rear-loading vehicles designed for efficiency and safety. Both roles demand navigating varied traffic conditions and adhering to strict waste management regulations to ensure timely and compliant waste collection.

Physical Demands and Ergonomics

Skip lorry drivers handle heavy, bulky skips requiring significant upper body strength and frequent loading tasks, often resulting in increased physical strain and a higher risk of musculoskeletal injuries. Rear loader drivers perform repetitive lifting and compacting motions, demanding endurance and precise ergonomic techniques to minimize fatigue and injury. Both roles require adherence to ergonomic best practices, but rear loader drivers typically face more continuous, repetitive physical demands compared to the episodic heavy lifting encountered by skip lorry drivers.

Route Planning and Navigation

Skip lorry drivers optimize route planning to accommodate multiple pickup points for large waste containers, focusing on efficient loading and drop-off sequences. Rear loader drivers prioritize navigating tighter urban spaces with frequent stops, requiring precise route adjustments to handle waste collection with hydraulic lift systems. Advanced GPS and route management software enhance both roles by reducing fuel consumption and improving time efficiency.

Interaction with Customers and Teams

Skip lorry drivers engage directly with customers to coordinate waste collection times and address site-specific requirements, ensuring efficient service delivery and customer satisfaction. Rear loader drivers collaborate closely with collection teams to manage waste loading processes safely and effectively, maintaining seamless communication to optimize route efficiency. Both roles require strong interpersonal skills to facilitate teamwork and provide reliable waste management solutions.

Career Progression and Training Opportunities

Skip lorry drivers often have straightforward entry requirements and gain experience through on-the-job training, allowing steady career progression into supervisory or logistics roles within waste management companies. Rear loader drivers typically require more specialized training due to operating complex machinery and adhering to stringent safety protocols, which can lead to advanced opportunities in equipment maintenance or operational management. Both roles offer pathways for career development, but rear loader drivers benefit from a broader scope of technical skills enhancing long-term job security.

Skip Lorry Driver vs Rear Loader Driver Infographic

jobdiv.com

jobdiv.com