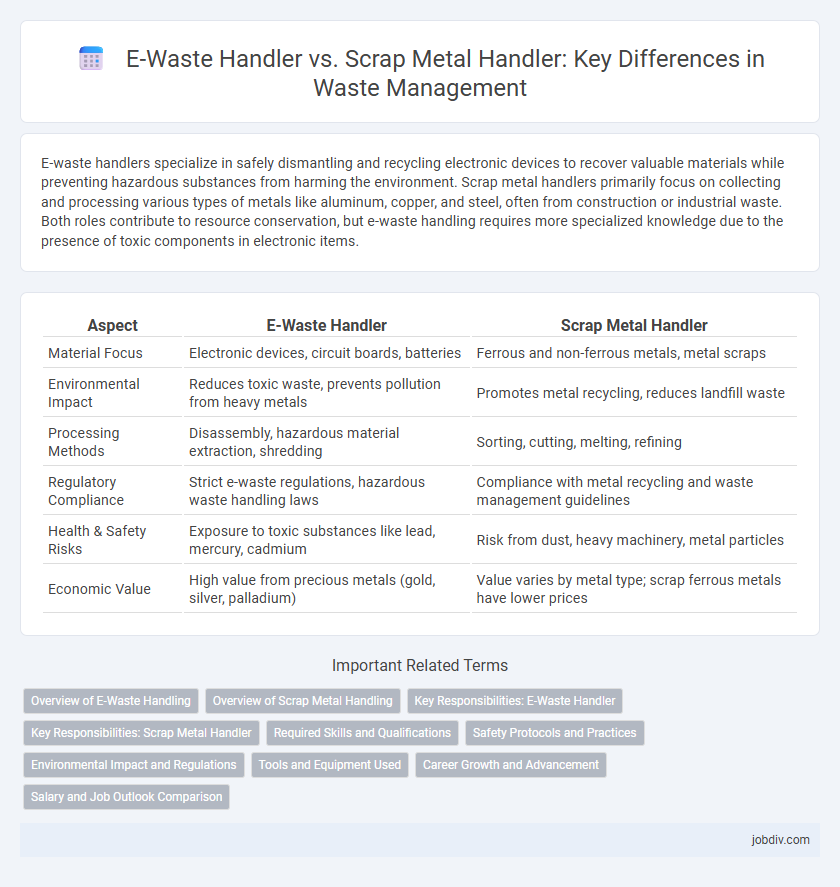

E-waste handlers specialize in safely dismantling and recycling electronic devices to recover valuable materials while preventing hazardous substances from harming the environment. Scrap metal handlers primarily focus on collecting and processing various types of metals like aluminum, copper, and steel, often from construction or industrial waste. Both roles contribute to resource conservation, but e-waste handling requires more specialized knowledge due to the presence of toxic components in electronic items.

Table of Comparison

| Aspect | E-Waste Handler | Scrap Metal Handler |

|---|---|---|

| Material Focus | Electronic devices, circuit boards, batteries | Ferrous and non-ferrous metals, metal scraps |

| Environmental Impact | Reduces toxic waste, prevents pollution from heavy metals | Promotes metal recycling, reduces landfill waste |

| Processing Methods | Disassembly, hazardous material extraction, shredding | Sorting, cutting, melting, refining |

| Regulatory Compliance | Strict e-waste regulations, hazardous waste handling laws | Compliance with metal recycling and waste management guidelines |

| Health & Safety Risks | Exposure to toxic substances like lead, mercury, cadmium | Risk from dust, heavy machinery, metal particles |

| Economic Value | High value from precious metals (gold, silver, palladium) | Value varies by metal type; scrap ferrous metals have lower prices |

Overview of E-Waste Handling

E-waste handlers specialize in the collection, processing, and recycling of electronic waste, ensuring proper disposal of hazardous components such as lead, mercury, and cadmium to minimize environmental impact. They employ advanced techniques to extract valuable materials like gold, silver, and copper from electronic devices, promoting resource recovery and reducing landfill waste. Unlike scrap metal handlers who primarily focus on ferrous and non-ferrous metals from industrial scrap, e-waste handlers require specialized knowledge of electronic circuitry and compliance with strict environmental regulations.

Overview of Scrap Metal Handling

Scrap metal handling involves the collection, sorting, and processing of discarded metal materials for recycling and resale, significantly contributing to resource conservation and waste reduction. Unlike e-waste handlers who specialize in dismantling electronic equipment to safely recover hazardous components, scrap metal handlers primarily focus on ferrous and non-ferrous metals, ensuring metals like steel, aluminum, and copper are properly separated and prepared for smelting. Efficient scrap metal management supports the circular economy by reducing the need for mining raw materials and lowering environmental impact associated with metal production.

Key Responsibilities: E-Waste Handler

E-Waste Handlers specialize in the collection, sorting, and safe disposal of electronic waste such as computers, smartphones, and batteries, ensuring hazardous materials like lead and mercury are properly managed to prevent environmental contamination. They implement recycling processes to recover valuable metals like gold, silver, and copper from discarded electronics, supporting resource conservation and reducing landfill impact. Compliance with regulations such as the Resource Conservation and Recovery Act (RCRA) and adherence to e-waste certification standards like R2 or e-Stewards are critical responsibilities to ensure environmentally sound handling practices.

Key Responsibilities: Scrap Metal Handler

Scrap metal handlers are responsible for collecting, sorting, and processing various types of scrap metal to prepare them for recycling or resale, ensuring metals are free from contaminants and hazardous materials. They operate heavy machinery to dismantle and compact metal waste, maintain accurate inventory records, and comply with environmental regulations to minimize pollution. Their role is critical in promoting sustainable metal recovery and reducing landfill waste.

Required Skills and Qualifications

E-waste handlers require specialized knowledge in electronics, including understanding circuit components, safe dismantling techniques, and hazardous material handling certifications like R2 or e-Stewards. Scrap metal handlers need skills in material identification, manual sorting, and may require certifications related to heavy machinery operation and safety compliance under OSHA standards. Both roles demand strong attention to detail and adherence to environmental regulations, but e-waste handlers emphasize technical expertise, whereas scrap metal handlers focus on physical sorting and logistics.

Safety Protocols and Practices

E-waste handlers adhere to strict safety protocols involving the use of personal protective equipment (PPE) such as gloves and masks to prevent exposure to hazardous substances like lead and mercury, while scrap metal handlers focus on procedures to avoid physical injuries and chemical contamination from metals like aluminum and steel. Proper segregation, safe dismantling techniques, and adherence to regulatory guidelines such as OSHA standards are critical for both roles to minimize health risks and environmental impact. Compliance with hazardous waste disposal laws and continuous training on handling toxic materials ensures safer operational practices in both e-waste and scrap metal management.

Environmental Impact and Regulations

E-waste handlers manage electronic waste containing hazardous materials like lead, mercury, and cadmium, requiring strict adherence to regulations such as the Basel Convention and the EPA's Resource Conservation and Recovery Act (RCRA) to prevent toxic contamination and promote safe recycling practices. Scrap metal handlers primarily deal with ferrous and non-ferrous metals, focusing on metal recovery and resale, facing regulations related to proper storage, shipment, and documentation to avoid illegal trade and environmental pollution from improper disposal. The environmental impact of e-waste handlers is significant due to the risk of releasing toxic substances into soil and water, whereas scrap metal handlers mainly address pollution from heavy metals and energy consumption during metal processing.

Tools and Equipment Used

E-waste handlers utilize specialized tools such as anti-static wrist straps, circuit board testers, and data destruction devices to safely dismantle and recycle electronic components. Scrap metal handlers primarily rely on heavy-duty equipment like hydraulic shears, metal shredders, and magnet cranes to sort and process ferrous and non-ferrous metals efficiently. Both industries prioritize safety gear including gloves, protective eyewear, and dust masks to minimize exposure to hazardous materials during handling and processing.

Career Growth and Advancement

E-waste handlers benefit from specialized knowledge in electronics recycling, which is increasingly vital due to rising global digital consumption, offering opportunities in tech-driven waste management sectors. Scrap metal handlers often access broader markets in construction and manufacturing but face more competition and fluctuating commodity prices, impacting career stability. Career growth for e-waste professionals is accelerated by evolving environmental regulations and advancements in material recovery technologies, positioning them for roles in sustainable resource management and policy development.

Salary and Job Outlook Comparison

E-waste handlers earn an average annual salary of $40,000, reflecting growing demand due to increased electronics consumption and stricter recycling regulations. Scrap metal handlers typically make around $35,000 per year, with job growth driven by industrial manufacturing and metal recycling industries. The job outlook for e-waste handlers is expected to grow 12% over the next decade, outpacing the 7% growth predicted for scrap metal handlers due to rising environmental concerns.

E-Waste Handler vs Scrap Metal Handler Infographic

jobdiv.com

jobdiv.com