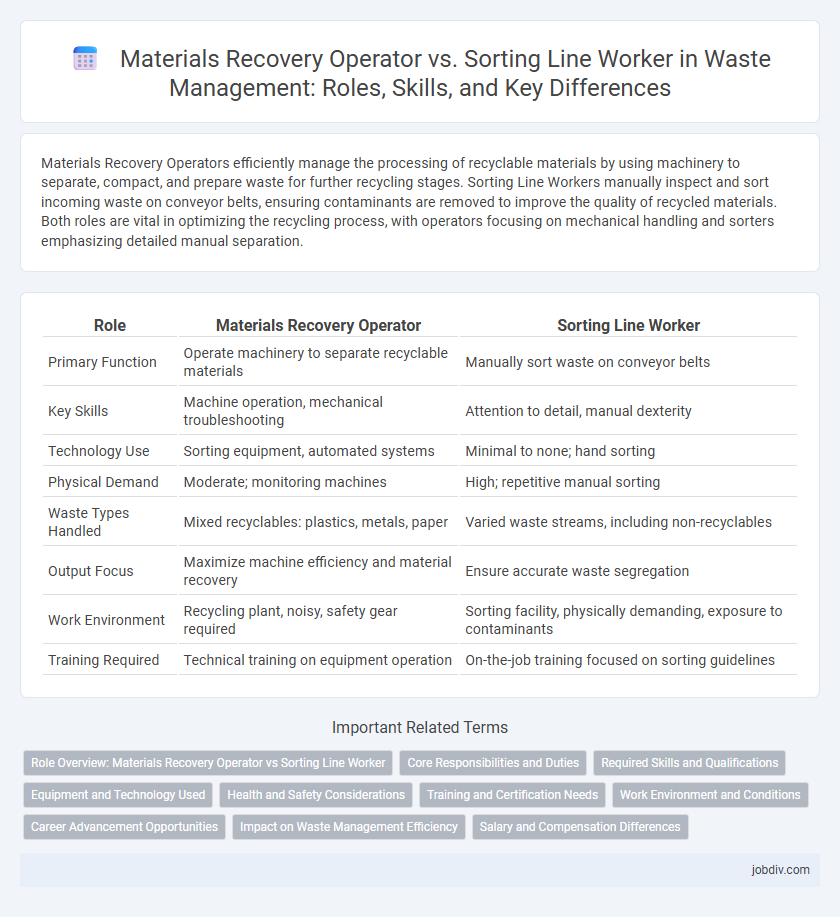

Materials Recovery Operators efficiently manage the processing of recyclable materials by using machinery to separate, compact, and prepare waste for further recycling stages. Sorting Line Workers manually inspect and sort incoming waste on conveyor belts, ensuring contaminants are removed to improve the quality of recycled materials. Both roles are vital in optimizing the recycling process, with operators focusing on mechanical handling and sorters emphasizing detailed manual separation.

Table of Comparison

| Role | Materials Recovery Operator | Sorting Line Worker |

|---|---|---|

| Primary Function | Operate machinery to separate recyclable materials | Manually sort waste on conveyor belts |

| Key Skills | Machine operation, mechanical troubleshooting | Attention to detail, manual dexterity |

| Technology Use | Sorting equipment, automated systems | Minimal to none; hand sorting |

| Physical Demand | Moderate; monitoring machines | High; repetitive manual sorting |

| Waste Types Handled | Mixed recyclables: plastics, metals, paper | Varied waste streams, including non-recyclables |

| Output Focus | Maximize machine efficiency and material recovery | Ensure accurate waste segregation |

| Work Environment | Recycling plant, noisy, safety gear required | Sorting facility, physically demanding, exposure to contaminants |

| Training Required | Technical training on equipment operation | On-the-job training focused on sorting guidelines |

Role Overview: Materials Recovery Operator vs Sorting Line Worker

Materials Recovery Operators manage advanced machinery to separate recyclables, enhancing efficiency in waste processing facilities. Sorting Line Workers perform manual sorting of materials on conveyor belts, ensuring contaminants are removed and recyclable items are properly classified. Both roles are crucial for optimizing material recovery and reducing landfill waste in solid waste management.

Core Responsibilities and Duties

Materials Recovery Operators manage the machinery that processes recyclable materials, ensuring equipment operates efficiently and maintenance is routinely performed. Sorting Line Workers manually separate recyclable items, identifying contaminants and categorizing materials during the sorting process. Both roles are essential for optimizing the recovery of materials in recycling facilities, with operators focusing on mechanical operations and workers on manual identification and sorting.

Required Skills and Qualifications

Materials Recovery Operators require proficiency in operating complex recycling machinery, knowledge of material identification, and adherence to safety protocols. Sorting Line Workers must possess keen visual acuity, manual dexterity, and the ability to quickly sort recyclable materials by type while maintaining high accuracy. Certifications in waste management or environmental safety, along with experience in recycling facilities, enhance qualifications for both roles.

Equipment and Technology Used

Materials Recovery Operators primarily utilize advanced sorting technologies such as optical sorters, magnets, and air classifiers to efficiently separate recyclable materials. Sorting Line Workers often rely on manual sorting techniques supported by conveyor belts and basic mechanical tools to identify and separate waste. Both roles benefit from evolving automation systems and real-time data analytics to enhance recovery rates and streamline processing.

Health and Safety Considerations

Materials Recovery Operators consistently use advanced machinery with built-in safety features, reducing direct exposure to hazardous waste and minimizing injury risks compared to Sorting Line Workers, who manually handle diverse recyclable materials on fast-moving conveyor belts. Sorting Line Workers face higher risks of musculoskeletal disorders, cuts, and exposure to biohazards due to repetitive motions and close contact with unsorted waste, necessitating stringent protective gear and regular health monitoring. Both roles require comprehensive training in hazard identification and emergency protocols to maintain workplace safety and prevent occupational illnesses.

Training and Certification Needs

Materials Recovery Operators require specialized training in handling automated sorting equipment and understanding material specifications for efficient recovery processes. Sorting Line Workers benefit from certification programs focused on manual sorting techniques, safety protocols, and material identification to ensure accurate separation. Both roles prioritize hands-on experience and compliance with environmental regulations to optimize waste diversion and recycling outcomes.

Work Environment and Conditions

Materials Recovery Operators work primarily in Materials Recovery Facilities (MRFs) where they operate heavy machinery to sort recyclable materials, often facing loud noise, dust, and physical strain due to continuous equipment handling. Sorting Line Workers perform manual sorting on conveyor belts, enduring repetitive motions, standing long hours, and exposure to contaminants in varying temperatures. Both roles demand strict adherence to safety protocols and can involve shift work in fast-paced, sometimes hazardous environments.

Career Advancement Opportunities

Materials Recovery Operators typically have greater career advancement opportunities by mastering automated sorting technologies and managing waste processing systems, while Sorting Line Workers often focus on manual sorting tasks with limited upward mobility. Expertise in materials identification, equipment maintenance, and process optimization enhances a Materials Recovery Operator's potential for promotion to supervisory or operations management roles. Industry demand for skilled operators to improve recycling efficiency contributes to accelerated career growth compared to more entry-level sorting positions.

Impact on Waste Management Efficiency

Materials Recovery Operators enhance waste management efficiency by using advanced machinery to separate recyclables, significantly increasing processing speed and reducing contamination rates. Sorting Line Workers contribute through manual identification and separation of materials, improving accuracy but often facing slower throughput. Combining both roles optimizes waste stream diversion, maximizing resource recovery and minimizing landfill contributions.

Salary and Compensation Differences

Materials Recovery Operators typically earn higher salaries than Sorting Line Workers due to their advanced responsibilities in processing and managing recyclable materials. According to industry data, the average annual salary for Materials Recovery Operators ranges from $35,000 to $45,000, while Sorting Line Workers usually earn between $28,000 and $36,000. Benefits packages for Materials Recovery Operators often include additional perks such as health insurance and paid training, reflecting the specialized skills required for their role.

Materials Recovery Operator vs Sorting Line Worker Infographic

jobdiv.com

jobdiv.com