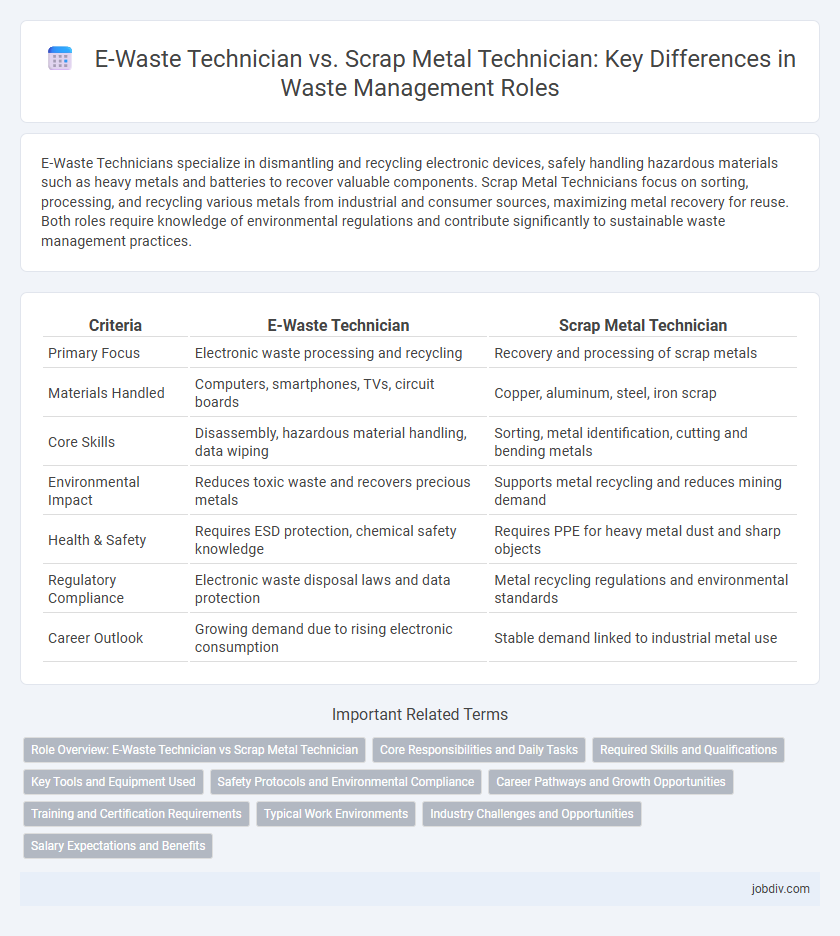

E-Waste Technicians specialize in dismantling and recycling electronic devices, safely handling hazardous materials such as heavy metals and batteries to recover valuable components. Scrap Metal Technicians focus on sorting, processing, and recycling various metals from industrial and consumer sources, maximizing metal recovery for reuse. Both roles require knowledge of environmental regulations and contribute significantly to sustainable waste management practices.

Table of Comparison

| Criteria | E-Waste Technician | Scrap Metal Technician |

|---|---|---|

| Primary Focus | Electronic waste processing and recycling | Recovery and processing of scrap metals |

| Materials Handled | Computers, smartphones, TVs, circuit boards | Copper, aluminum, steel, iron scrap |

| Core Skills | Disassembly, hazardous material handling, data wiping | Sorting, metal identification, cutting and bending metals |

| Environmental Impact | Reduces toxic waste and recovers precious metals | Supports metal recycling and reduces mining demand |

| Health & Safety | Requires ESD protection, chemical safety knowledge | Requires PPE for heavy metal dust and sharp objects |

| Regulatory Compliance | Electronic waste disposal laws and data protection | Metal recycling regulations and environmental standards |

| Career Outlook | Growing demand due to rising electronic consumption | Stable demand linked to industrial metal use |

Role Overview: E-Waste Technician vs Scrap Metal Technician

E-Waste Technicians specialize in dismantling, sorting, and safely processing electronic waste to recover valuable components like precious metals and ensure hazardous materials are handled properly. Scrap Metal Technicians focus on identifying, separating, and preparing various metal types from industrial and household scrap for recycling and resale. Both roles emphasize environmental compliance and resource recovery but differ in material specialization and processing techniques.

Core Responsibilities and Daily Tasks

E-Waste Technicians specialize in the safe dismantling, sorting, and recycling of electronic devices, ensuring hazardous materials like lead and mercury are properly managed to prevent environmental contamination. Scrap Metal Technicians focus on identifying, sorting, and processing various metals such as aluminum, copper, and steel to prepare them for melting and reuse in manufacturing. Both roles require adherence to safety protocols and efficiency in material handling, but E-Waste Technicians work more with electronic components, while Scrap Metal Technicians handle bulk metal materials.

Required Skills and Qualifications

E-Waste Technicians require expertise in electronic component dismantling, circuit board analysis, and familiarity with hazardous material handling certifications such as OSHA HAZWOPER. Scrap Metal Technicians must possess proficiency in metal sorting, use of industrial shredders, and understanding of metallurgical properties, often supported by certifications in welding or metal fabrication. Both roles demand strong safety knowledge, attention to detail, and compliance with environmental regulations to ensure effective recycling and waste management.

Key Tools and Equipment Used

E-Waste Technicians primarily use specialized diagnostic tools, soldering equipment, and anti-static devices to safely dismantle and repair electronic components, ensuring proper handling of hazardous materials. Scrap Metal Technicians rely on heavy-duty cutting tools, magnets, shears, and balers to sort, process, and compact various metals for recycling. Both roles require safety gear like gloves, goggles, and protective clothing tailored to their specific handling and material risks.

Safety Protocols and Environmental Compliance

E-Waste Technicians adhere to stringent safety protocols involving the handling of hazardous materials such as lead, mercury, and cadmium, ensuring proper dismantling and disposal to mitigate environmental contamination. Scrap Metal Technicians focus on safely processing metals like steel, aluminum, and copper, following regulations that prevent occupational hazards and promote recycling efficiency. Both roles require compliance with EPA regulations and OSHA standards to minimize health risks and environmental impact during waste recovery operations.

Career Pathways and Growth Opportunities

E-Waste Technicians specialize in the safe dismantling, recycling, and disposal of electronic devices, with career pathways leading to roles in environmental compliance and sustainable technology management. Scrap Metal Technicians focus on sorting, processing, and selling metal materials, offering growth opportunities in metal recovery operations and supply chain management. Both careers benefit from increasing demand for recycling solutions, but E-Waste Technicians often experience faster growth due to rising global electronic consumption and stricter environmental regulations.

Training and Certification Requirements

E-Waste Technicians require specialized training in electronic component handling, hazardous material management, and data destruction, often certified through programs like the Certified Electronics Recycler (CER) or R2 Responsible Recycling standards. Scrap Metal Technicians undergo training focused on metal identification, safe dismantling, and environmental compliance, with certifications available from organizations such as the Institute of Scrap Recycling Industries (ISRI) or OSHA safety courses. Both roles demand ongoing education to meet evolving regulations and industry best practices in waste management.

Typical Work Environments

E-Waste Technicians primarily operate in electronic recycling centers, repair shops, and hazardous waste facilities where handling and processing of discarded electronic devices take place. Scrap Metal Technicians generally work in scrapyards, metal recycling plants, and manufacturing sites focusing on sorting, dismantling, and processing various metals for reuse. Both roles require adherence to safety protocols and environmental regulations, but the work environments differ based on the materials handled and the associated hazards.

Industry Challenges and Opportunities

E-Waste Technicians face the challenge of safely dismantling complex electronic devices to recover valuable materials like gold, silver, and rare earth metals, while addressing hazardous substances such as lead and mercury. Scrap Metal Technicians encounter obstacles in sorting and processing diverse metal alloys to maximize recycling efficiency and market value amidst fluctuating commodity prices. Both roles present opportunities in advancing sustainable waste management practices through technological innovation and regulatory compliance within the circular economy framework.

Salary Expectations and Benefits

E-Waste Technicians typically earn an average salary ranging from $35,000 to $50,000 annually, with benefits often including health insurance and opportunities for specialized certification in electronics recycling. Scrap Metal Technicians generally have a salary range between $30,000 and $45,000 per year, accompanied by benefits such as hazard pay and pension plans due to the physically demanding nature of metal recycling work. Salary expectations for both roles vary by location, experience, and employer, while benefits packages tend to reflect industry standards and workplace safety regulations.

E-Waste Technician vs Scrap Metal Technician Infographic

jobdiv.com

jobdiv.com