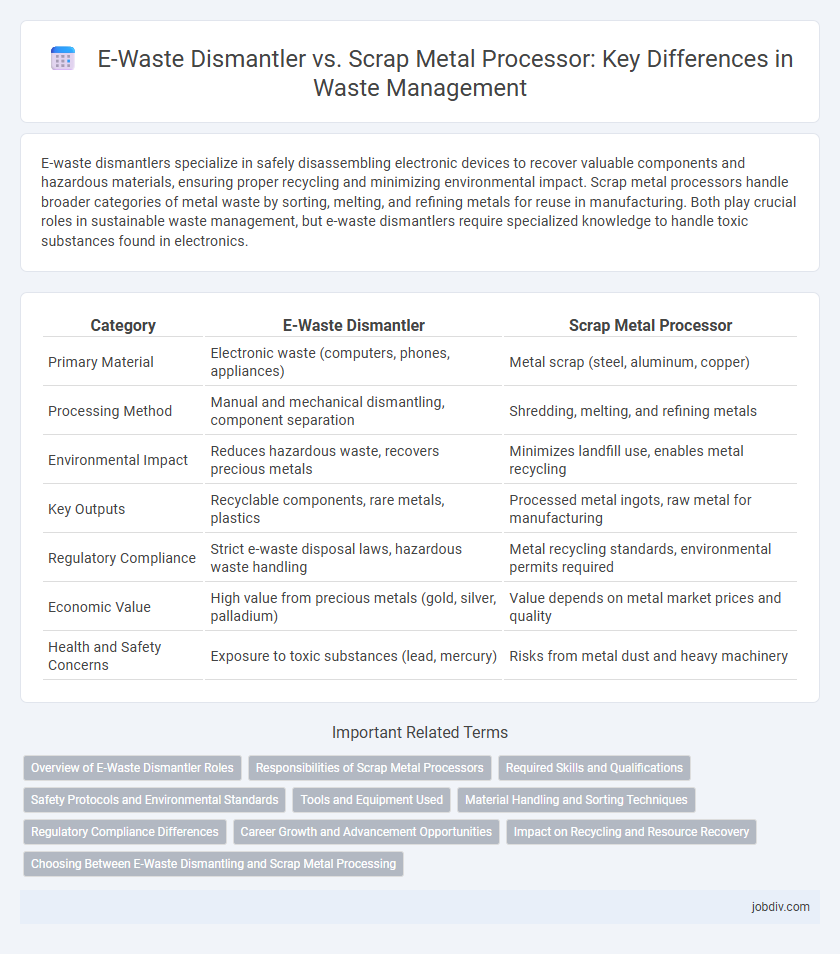

E-waste dismantlers specialize in safely disassembling electronic devices to recover valuable components and hazardous materials, ensuring proper recycling and minimizing environmental impact. Scrap metal processors handle broader categories of metal waste by sorting, melting, and refining metals for reuse in manufacturing. Both play crucial roles in sustainable waste management, but e-waste dismantlers require specialized knowledge to handle toxic substances found in electronics.

Table of Comparison

| Category | E-Waste Dismantler | Scrap Metal Processor |

|---|---|---|

| Primary Material | Electronic waste (computers, phones, appliances) | Metal scrap (steel, aluminum, copper) |

| Processing Method | Manual and mechanical dismantling, component separation | Shredding, melting, and refining metals |

| Environmental Impact | Reduces hazardous waste, recovers precious metals | Minimizes landfill use, enables metal recycling |

| Key Outputs | Recyclable components, rare metals, plastics | Processed metal ingots, raw metal for manufacturing |

| Regulatory Compliance | Strict e-waste disposal laws, hazardous waste handling | Metal recycling standards, environmental permits required |

| Economic Value | High value from precious metals (gold, silver, palladium) | Value depends on metal market prices and quality |

| Health and Safety Concerns | Exposure to toxic substances (lead, mercury) | Risks from metal dust and heavy machinery |

Overview of E-Waste Dismantler Roles

E-waste dismantlers play a critical role in the electronics recycling industry by carefully disassembling outdated or discarded electronic devices to salvage valuable components such as circuit boards, batteries, and plastics. This process reduces environmental hazards by extracting toxic materials like lead, mercury, and cadmium before proper disposal or further processing. Unlike scrap metal processors who primarily focus on melting and recycling metals, e-waste dismantlers emphasize manual separation and sorting to maximize resource recovery and minimize ecological impact.

Responsibilities of Scrap Metal Processors

Scrap metal processors are responsible for sorting, cleaning, and grading recyclable metals to prepare them for efficient melting and repurposing. They operate heavy machinery to shred, compress, and separate ferrous and non-ferrous metals from mixed waste streams. Their role ensures compliance with environmental regulations by minimizing hazardous contaminants and maximizing material recovery from e-waste.

Required Skills and Qualifications

E-waste dismantlers require specialized knowledge in electronic components, circuit board identification, and safe handling of hazardous materials to ensure environmentally compliant dismantling. Scrap metal processors focus on skills related to metal sorting, heavy machinery operation, and understanding of metallurgical properties to efficiently separate and process recyclable metals. Both roles demand adherence to safety protocols, but e-waste dismantlers often need certifications in hazardous waste management, while scrap metal processors typically require training in industrial machinery and quality control.

Safety Protocols and Environmental Standards

E-waste dismantlers implement strict safety protocols such as the use of personal protective equipment (PPE) and proper handling of hazardous components like batteries and mercury to prevent toxic exposure. Scrap metal processors prioritize environmental standards by employing dust suppression systems and recycling techniques that reduce emissions and minimize landfill waste. Both industries must adhere to regulatory frameworks like R2 (Responsible Recycling) and e-Stewards certification to ensure safe and sustainable operations.

Tools and Equipment Used

E-waste dismantlers use specialized tools such as anti-static screwdrivers, wire cutters, and soldering irons to carefully separate valuable components like circuit boards, batteries, and connectors without causing damage. Scrap metal processors rely on heavy machinery including magnetic separators, shredders, and shears to efficiently break down and sort ferrous and non-ferrous metals for recycling. Precision instruments in e-waste dismantling enable component recovery, while the robust equipment in scrap metal processing supports bulk metal handling and material recovery.

Material Handling and Sorting Techniques

E-waste dismantlers specialize in careful disassembly of electronic devices to separate hazardous components like batteries and circuit boards, employing manual and automated sorting techniques such as optical sorting and eddy current separators. Scrap metal processors focus on bulk material handling by shredding, magnetic separation, and shredding to recover ferrous and non-ferrous metals efficiently from mixed metal streams. Advanced sorting technologies, including sensor-based sorting and air classification, enhance recovery rates and ensure contaminant-free recyclables in both e-waste and scrap metal processing operations.

Regulatory Compliance Differences

E-waste dismantlers must adhere to strict environmental regulations such as the Resource Conservation and Recovery Act (RCRA) and the e-Stewards or R2 certification standards, ensuring safe handling of hazardous materials like lead and mercury. Scrap metal processors primarily follow regulations under the Scrap Metal Theft Reduction Act and local waste management laws, focusing on preventing illegal metal trading and proper disposal of non-hazardous metals. Compliance disparities arise from the distinct waste streams managed, with e-waste dismantlers facing more rigorous hazardous waste controls compared to the relatively less stringent scrap metal processing oversight.

Career Growth and Advancement Opportunities

E-Waste dismantlers benefit from specialized skills in electronics recovery and hazardous material handling, which leads to niche career opportunities in recycling technology and environmental compliance. Scrap metal processors develop expertise in metal sorting and alloy identification, offering advancement into operations management and supply chain coordination within the metals industry. Both paths provide strong career growth, with E-Waste dismantling focusing on sustainability innovation and scrap metal processing emphasizing industrial efficiency.

Impact on Recycling and Resource Recovery

E-waste dismantlers specialize in carefully disassembling electronic devices to separate valuable components like gold, silver, and rare earth metals, significantly enhancing resource recovery efficiency. Scrap metal processors primarily focus on melting down mixed metal scrap, which often leads to the loss of precious elements embedded in complex electronic waste. The targeted approach of e-waste dismantlers results in higher recycling rates and reduced environmental contamination compared to the generalized processing methods used by scrap metal recyclers.

Choosing Between E-Waste Dismantling and Scrap Metal Processing

Choosing between e-waste dismantling and scrap metal processing depends on the specific waste type and environmental impact goals. E-waste dismantlers specialize in safely separating hazardous components like batteries and circuit boards, ensuring compliance with electronic waste regulations and promoting resource recovery. Scrap metal processors focus on sorting and recycling ferrous and non-ferrous metals from general waste streams, optimizing metal reuse but typically lacking the detailed treatment required for electronics.

E-Waste Dismantler vs Scrap Metal Processor Infographic

jobdiv.com

jobdiv.com