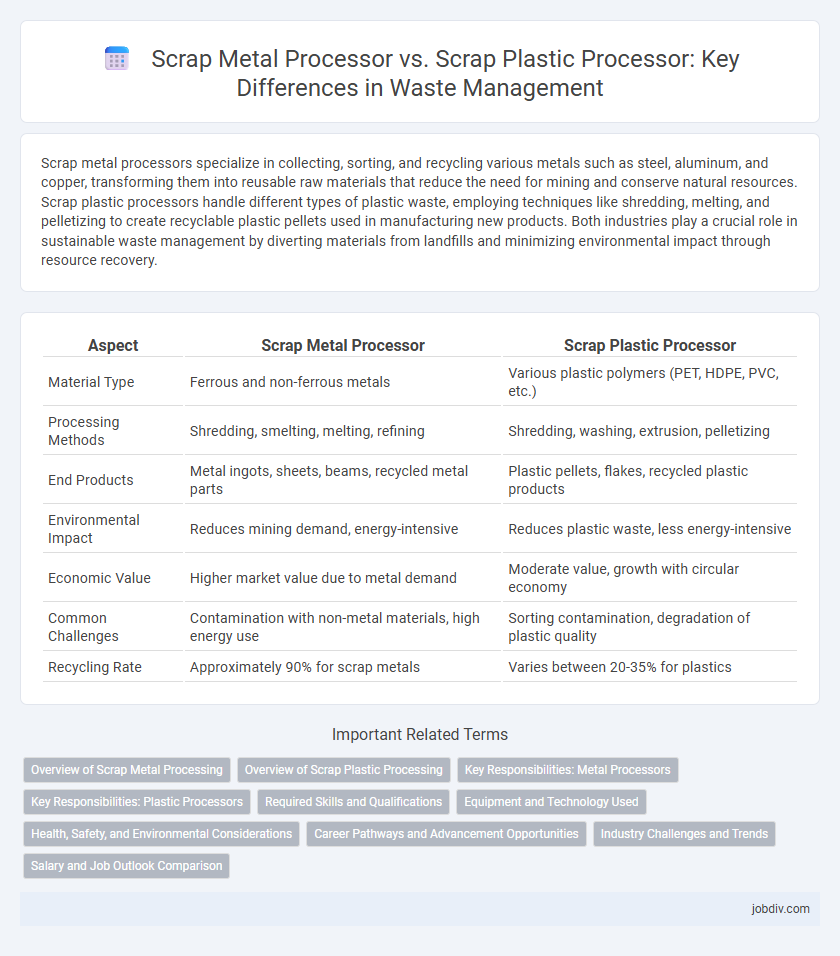

Scrap metal processors specialize in collecting, sorting, and recycling various metals such as steel, aluminum, and copper, transforming them into reusable raw materials that reduce the need for mining and conserve natural resources. Scrap plastic processors handle different types of plastic waste, employing techniques like shredding, melting, and pelletizing to create recyclable plastic pellets used in manufacturing new products. Both industries play a crucial role in sustainable waste management by diverting materials from landfills and minimizing environmental impact through resource recovery.

Table of Comparison

| Aspect | Scrap Metal Processor | Scrap Plastic Processor |

|---|---|---|

| Material Type | Ferrous and non-ferrous metals | Various plastic polymers (PET, HDPE, PVC, etc.) |

| Processing Methods | Shredding, smelting, melting, refining | Shredding, washing, extrusion, pelletizing |

| End Products | Metal ingots, sheets, beams, recycled metal parts | Plastic pellets, flakes, recycled plastic products |

| Environmental Impact | Reduces mining demand, energy-intensive | Reduces plastic waste, less energy-intensive |

| Economic Value | Higher market value due to metal demand | Moderate value, growth with circular economy |

| Common Challenges | Contamination with non-metal materials, high energy use | Sorting contamination, degradation of plastic quality |

| Recycling Rate | Approximately 90% for scrap metals | Varies between 20-35% for plastics |

Overview of Scrap Metal Processing

Scrap metal processing involves the collection, sorting, and recycling of various metals such as steel, aluminum, copper, and iron to reduce environmental impact and conserve natural resources. Scrap metal processors utilize advanced machinery to shred, melt, and purify metals, enabling the production of high-quality recycled products for manufacturing industries. Unlike scrap plastic processing, which deals primarily with polymer materials, scrap metal processing emphasizes material purity and metallurgical properties to ensure efficient recycling and reuse in heavy industries.

Overview of Scrap Plastic Processing

Scrap plastic processing involves sorting, cleaning, shredding, and melting plastic waste to create reusable raw materials for manufacturing. Unlike scrap metal processing, which deals with the recovery and refining of metals like steel and aluminum, plastic processing requires specialized techniques to handle different polymer types and contamination levels. Advanced technologies such as optical sorting and chemical recycling enhance efficiency and quality in scrap plastic processing, supporting circular economy goals.

Key Responsibilities: Metal Processors

Scrap metal processors manage the collection, sorting, and melting of ferrous and non-ferrous metals, ensuring efficient recovery and recycling of valuable metal materials. They operate heavy machinery to shred, shear, and compact metals, while adhering to environmental regulations and safety standards. Key responsibilities also include inventory management, quality control, and coordinating with suppliers and buyers to optimize material throughput and profitability.

Key Responsibilities: Plastic Processors

Scrap plastic processors are responsible for sorting, cleaning, and shredding various types of plastic waste to prepare materials for recycling. They ensure the removal of contaminants such as labels, adhesives, and non-recyclable plastics to maintain high-quality output. Their role also includes operating specialized machinery to melt and pelletize plastic, facilitating efficient reuse in manufacturing.

Required Skills and Qualifications

Scrap metal processors require expertise in metallurgy, heavy machinery operation, and proficiency in sorting various metal alloys to maximize recycling efficiency. Scrap plastic processors need knowledge of polymer types, plastic identification techniques, and experience with shredding and washing equipment to ensure quality material recovery. Both roles demand strong attention to detail, safety compliance, and the ability to operate industrial processing systems.

Equipment and Technology Used

Scrap metal processors rely on heavy-duty equipment such as shredders, magnetic separators, and shears to efficiently sort and break down ferrous and non-ferrous metals. In contrast, scrap plastic processors use advanced technologies including granulators, washing systems, and optical sorters to clean, shred, and categorize various plastic types. Both industries employ automation and sensor-based sorting to enhance material purity and operational efficiency.

Health, Safety, and Environmental Considerations

Scrap metal processors face significant health risks from heavy metal exposure and airborne particulates, necessitating stringent safety protocols and protective equipment to minimize respiratory and dermal hazards. Scrap plastic processors contend with the release of toxic fumes and microplastic pollution, requiring advanced ventilation systems and containment measures to protect workers and prevent environmental contamination. Both industries must implement robust waste management practices and emissions controls to mitigate soil, air, and water pollution, ensuring compliance with environmental regulations and safeguarding community health.

Career Pathways and Advancement Opportunities

Scrap metal processors often have clearer career pathways due to the industry's established demand and integration with manufacturing and recycling sectors, offering advancement into supervisory, logistics, or equipment maintenance roles. Scrap plastic processors face growing opportunities driven by increased environmental regulations and innovation in plastic recycling technologies, enabling career growth in process engineering, quality control, and sustainability management. Both fields provide specialized skill development, but scrap metal processing tends to offer more traditional advancement routes, while scrap plastic processing is expanding with emerging markets and green technology initiatives.

Industry Challenges and Trends

Scrap metal processors face increasing pressure to improve sorting technologies to handle mixed-metal alloys and comply with stricter environmental regulations. In contrast, scrap plastic processors grapple with contamination issues and the complexity of recycling multi-layered and composite plastics, driving innovations in chemical recycling and enhanced sorting systems. Both industries are trending towards automation and digital tracking to increase efficiency and transparency in waste management supply chains.

Salary and Job Outlook Comparison

Scrap metal processors typically earn higher median salaries, ranging from $35,000 to $55,000 annually, due to the value and demand for metals in manufacturing and recycling industries. Scrap plastic processors generally report lower wages, averaging between $28,000 and $45,000, influenced by fluctuating plastic market prices and recycling challenges. The job outlook for scrap metal processors is positive, driven by steady industrial demand and advancements in metal recycling technologies, whereas scrap plastic processing faces moderate growth due to evolving environmental regulations and increased emphasis on plastic waste reduction.

Scrap Metal Processor vs Scrap Plastic Processor Infographic

jobdiv.com

jobdiv.com