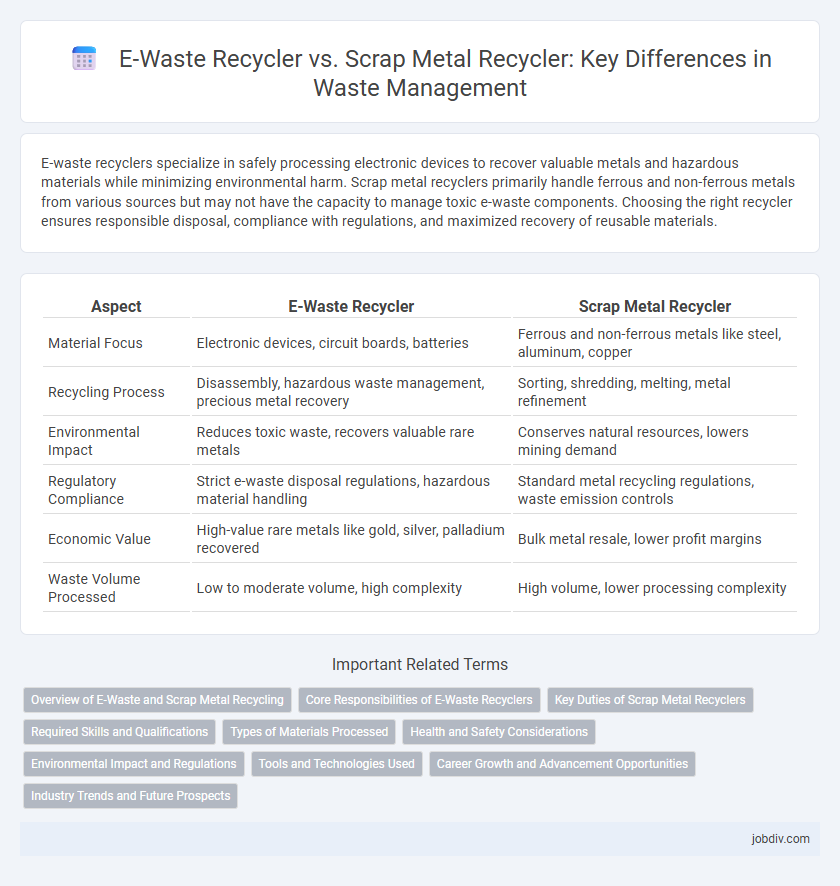

E-waste recyclers specialize in safely processing electronic devices to recover valuable metals and hazardous materials while minimizing environmental harm. Scrap metal recyclers primarily handle ferrous and non-ferrous metals from various sources but may not have the capacity to manage toxic e-waste components. Choosing the right recycler ensures responsible disposal, compliance with regulations, and maximized recovery of reusable materials.

Table of Comparison

| Aspect | E-Waste Recycler | Scrap Metal Recycler |

|---|---|---|

| Material Focus | Electronic devices, circuit boards, batteries | Ferrous and non-ferrous metals like steel, aluminum, copper |

| Recycling Process | Disassembly, hazardous waste management, precious metal recovery | Sorting, shredding, melting, metal refinement |

| Environmental Impact | Reduces toxic waste, recovers valuable rare metals | Conserves natural resources, lowers mining demand |

| Regulatory Compliance | Strict e-waste disposal regulations, hazardous material handling | Standard metal recycling regulations, waste emission controls |

| Economic Value | High-value rare metals like gold, silver, palladium recovered | Bulk metal resale, lower profit margins |

| Waste Volume Processed | Low to moderate volume, high complexity | High volume, lower processing complexity |

Overview of E-Waste and Scrap Metal Recycling

E-Waste recycling involves processing discarded electronic devices like computers, smartphones, and TVs to recover valuable metals such as gold, silver, and copper while safely managing hazardous substances like lead and mercury. Scrap metal recycling focuses on collecting and melting down ferrous and non-ferrous metals from industrial waste, vehicles, and construction debris for reuse in manufacturing. Both processes contribute significantly to resource conservation, energy savings, and environmental protection by reducing landfill waste and minimizing the need for raw material extraction.

Core Responsibilities of E-Waste Recyclers

E-waste recyclers specialize in the proper dismantling, processing, and safe disposal of electronic devices to recover valuable materials like gold, silver, and rare earth metals while preventing environmental pollution. They adhere to strict regulatory standards to handle hazardous components such as lead, mercury, and cadmium found in electronics. Their core responsibilities include data destruction, material recovery, and ensuring electronics are processed in ways that minimize landfill waste and promote sustainable resource management.

Key Duties of Scrap Metal Recyclers

Scrap metal recyclers specialize in collecting, sorting, and processing various metals such as steel, aluminum, copper, and iron for reuse in manufacturing. They operate heavy machinery to dismantle, shred, and melt down metal products, ensuring the removal of non-metal contaminants to maintain material purity. Their key duties also include inspecting, grading, and managing metal inventory to optimize recycling efficiency and comply with environmental regulations.

Required Skills and Qualifications

E-waste recyclers require specialized knowledge in handling hazardous materials, electronic components, and data security protocols to ensure safe dismantling and recycling of devices. Scrap metal recyclers need skills in metal identification, sorting, and proficient use of heavy machinery for processing ferrous and non-ferrous metals. Both roles demand compliance with environmental regulations, but e-waste recyclers often require certifications related to electronic waste management and hazardous material handling.

Types of Materials Processed

E-waste recyclers specialize in processing electronic devices such as computers, smartphones, and televisions, recovering valuable components like precious metals, circuit boards, and batteries. Scrap metal recyclers focus on ferrous and non-ferrous metals including steel, aluminum, copper, and brass, often sourced from automotive parts, construction debris, and household appliances. Both recyclers employ distinct methods tailored to the material properties, ensuring efficient recovery and reducing environmental impact.

Health and Safety Considerations

E-waste recyclers handle hazardous materials such as lead, mercury, and cadmium, requiring specialized protective equipment and strict protocols to prevent exposure and environmental contamination. Scrap metal recyclers primarily deal with metals that pose fewer toxic risks but must address physical injuries from heavy machinery and sharp objects through safety training and equipment. Both industries emphasize compliance with OSHA standards and employ risk management strategies to safeguard worker health and maintain workplace safety.

Environmental Impact and Regulations

E-waste recyclers specialize in processing electronic waste, extracting valuable metals while safely managing hazardous substances such as lead, mercury, and cadmium, thereby significantly reducing environmental contamination. Scrap metal recyclers primarily handle ferrous and non-ferrous metals from industrial and consumer sources but may not be equipped to safely process toxic electronic components, posing higher environmental risks if not properly regulated. Strict regulations like the Basel Convention and R2 certifications govern e-waste recycling to ensure responsible handling and disposal, whereas scrap metal recycling is often subject to less stringent environmental oversight, impacting the overall ecological footprint of each recycling method.

Tools and Technologies Used

E-waste recyclers utilize specialized tools such as hydraulic shredders, conveyor belts, and advanced sorting technologies including optical scanners and eddy current separators to safely dismantle and recover valuable materials from electronic devices. Scrap metal recyclers primarily rely on heavy-duty machinery like metal shears, magnets, and industrial crushers to process ferrous and non-ferrous metals, using technologies focused on metal identification and separation. Both sectors employ automated systems and environmentally compliant techniques to maximize material recovery while minimizing environmental impact.

Career Growth and Advancement Opportunities

E-waste recyclers specialize in recovering valuable materials from electronic devices, offering career growth in high-tech fields like materials science and environmental technology. Scrap metal recyclers focus on processing ferrous and non-ferrous metals, with advancement opportunities tied to operations management and logistics within a traditional recycling industry. Both sectors provide distinct pathways for professional development, with e-waste recycling often aligning with emerging technologies and stricter environmental regulations.

Industry Trends and Future Prospects

E-waste recyclers specialize in safely processing electronic components, recovering valuable metals like gold, silver, and copper while mitigating environmental hazards from toxic substances such as lead and mercury. Scrap metal recyclers primarily handle ferrous and non-ferrous metals from various industries, contributing to a circular economy by supplying raw materials to steel, automotive, and construction sectors. Industry trends indicate increasing regulatory pressures and technological advancements favor e-waste recycling growth, with future prospects favoring integrated recycling solutions that combine electronic and metal recovery for enhanced resource efficiency.

E-Waste Recycler vs Scrap Metal Recycler Infographic

jobdiv.com

jobdiv.com