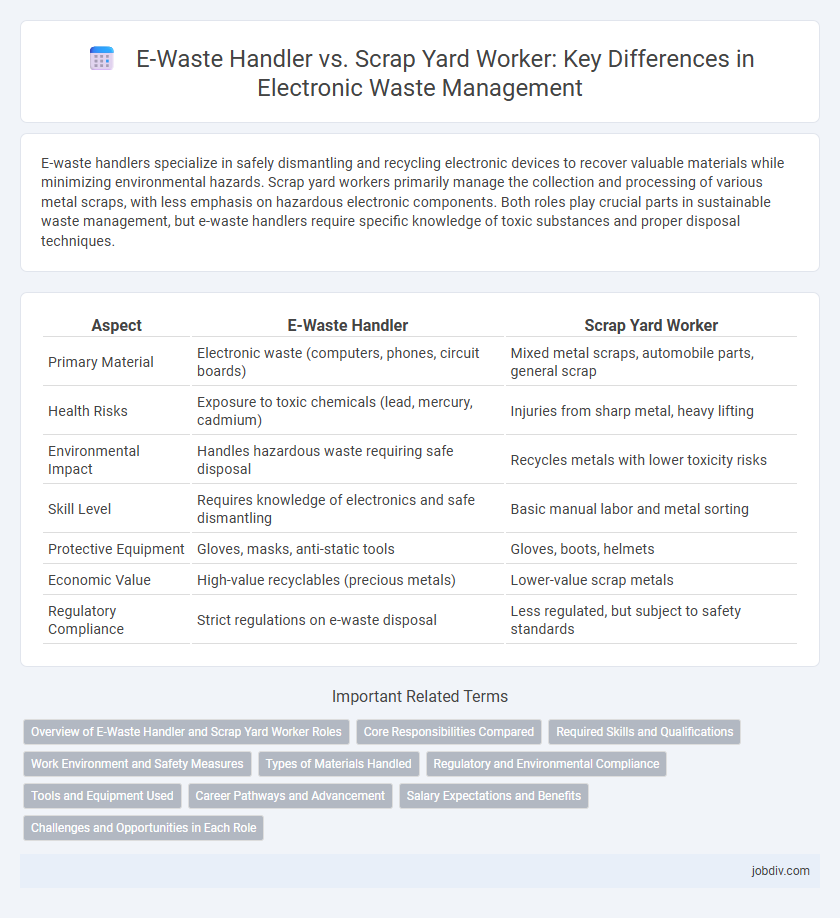

E-waste handlers specialize in safely dismantling and recycling electronic devices to recover valuable materials while minimizing environmental hazards. Scrap yard workers primarily manage the collection and processing of various metal scraps, with less emphasis on hazardous electronic components. Both roles play crucial parts in sustainable waste management, but e-waste handlers require specific knowledge of toxic substances and proper disposal techniques.

Table of Comparison

| Aspect | E-Waste Handler | Scrap Yard Worker |

|---|---|---|

| Primary Material | Electronic waste (computers, phones, circuit boards) | Mixed metal scraps, automobile parts, general scrap |

| Health Risks | Exposure to toxic chemicals (lead, mercury, cadmium) | Injuries from sharp metal, heavy lifting |

| Environmental Impact | Handles hazardous waste requiring safe disposal | Recycles metals with lower toxicity risks |

| Skill Level | Requires knowledge of electronics and safe dismantling | Basic manual labor and metal sorting |

| Protective Equipment | Gloves, masks, anti-static tools | Gloves, boots, helmets |

| Economic Value | High-value recyclables (precious metals) | Lower-value scrap metals |

| Regulatory Compliance | Strict regulations on e-waste disposal | Less regulated, but subject to safety standards |

Overview of E-Waste Handler and Scrap Yard Worker Roles

E-Waste Handlers specialize in managing, sorting, and recycling electronic waste to prevent harmful environmental impact and recover valuable materials such as precious metals and rare earth elements. Scrap Yard Workers focus on processing and sorting various types of scrap materials, including metals and plastics, for resale and reuse, often operating heavy machinery and ensuring compliance with safety regulations. Both roles are crucial in the waste management industry, emphasizing sustainability, resource recovery, and environmental protection.

Core Responsibilities Compared

E-Waste handlers specialize in the safe dismantling, sorting, and recycling of electronic components, adhering to environmental regulations to prevent hazardous material contamination. Scrap yard workers primarily manage the collection, segregation, and processing of various metal and material scraps for resale or recycling, often focusing on manual labor and mechanical equipment operation. Both roles require attention to safety and material classification but differ significantly in handling electronic waste versus general scrap metals.

Required Skills and Qualifications

E-Waste handlers require specialized knowledge of electronic component identification, safe dismantling techniques, and hazardous material handling certifications to prevent environmental contamination. Scrap yard workers need skills in heavy machinery operation, metal sorting, and physical stamina, often with basic safety training and equipment handling certification. Both roles demand adherence to regulatory compliance but differ primarily in technical expertise and safety protocols related to the nature of the waste handled.

Work Environment and Safety Measures

E-waste handlers operate in controlled environments with strict adherence to electronic material recycling protocols, using specialized tools and protective gear to prevent exposure to hazardous substances like lead and mercury. In contrast, scrap yard workers often work outdoors in less regulated settings, facing risks from heavy machinery, sharp metal debris, and inconsistent safety practices. Both roles require awareness of safety standards, but e-waste handling mandates more rigorous chemical safety measures and waste classification compliance to minimize environmental and health impacts.

Types of Materials Handled

E-waste handlers primarily manage electronic devices such as computers, smartphones, and circuit boards, focusing on the recovery of valuable metals like gold, silver, and copper. Scrap yard workers deal mostly with bulk metal scraps including steel, aluminum, and iron from vehicles, appliances, and construction debris. Both roles require specialized knowledge in sorting and processing materials to ensure proper recycling and environmental compliance.

Regulatory and Environmental Compliance

E-waste handlers adhere to stringent regulatory standards including the Waste Electrical and Electronic Equipment Directive (WEEE) and the Resource Conservation and Recovery Act (RCRA), ensuring proper disposal and recycling of hazardous electronic materials. Scrap yard workers typically focus on broader materials without specialized e-waste protocols, often facing less rigorous environmental compliance demands. Proper e-waste management reduces toxic contamination risks in landfills, whereas scrap yards must balance metal recovery with environmental protection under local and federal regulations.

Tools and Equipment Used

E-waste handlers specialize in using electronic testing devices, soldering irons, and anti-static tools to safely dismantle and recycle electronic components, ensuring hazardous materials are properly managed. Scrap yard workers primarily rely on heavy machinery such as cranes, scrap metal shears, and cutting torches to break down and process large volumes of metal and other materials. Both roles require personal protective equipment (PPE) like gloves, safety goggles, and helmets, but e-waste handlers emphasize precision instruments to handle sensitive electronic waste.

Career Pathways and Advancement

E-Waste handlers specialize in safely dismantling and recycling electronic components, offering career advancement through certifications in hazardous materials management and sustainable disposal techniques. Scrap yard workers primarily focus on sorting and processing various metals and materials, with growth opportunities in equipment operation, logistics, and management roles within scrap recycling centers. Both career paths provide avenues for specialization and leadership, but e-waste handling increasingly demands technical expertise aligned with environmental regulations and technological innovation.

Salary Expectations and Benefits

E-waste handlers typically earn higher salaries compared to scrap yard workers due to the specialized skills required for managing hazardous electronic components and compliance with environmental regulations. Benefits for e-waste handlers often include health insurance, safety training, and opportunities for certification in hazardous waste management, which are less common in scrap yard roles. Scrap yard workers, while earning lower average wages, may receive benefits such as union representation and job stability in scrap metal recycling sectors.

Challenges and Opportunities in Each Role

E-waste handlers face challenges such as managing hazardous materials and ensuring environmentally compliant disposal, which require specialized training and access to recycling technology. Scrap yard workers often deal with physical risks from heavy machinery and manual sorting but benefit from stable demand due to ongoing metal recycling needs. Both roles present opportunities for skill development and contribute significantly to sustainable waste management and resource recovery.

E-Waste Handler vs Scrap Yard Worker Infographic

jobdiv.com

jobdiv.com