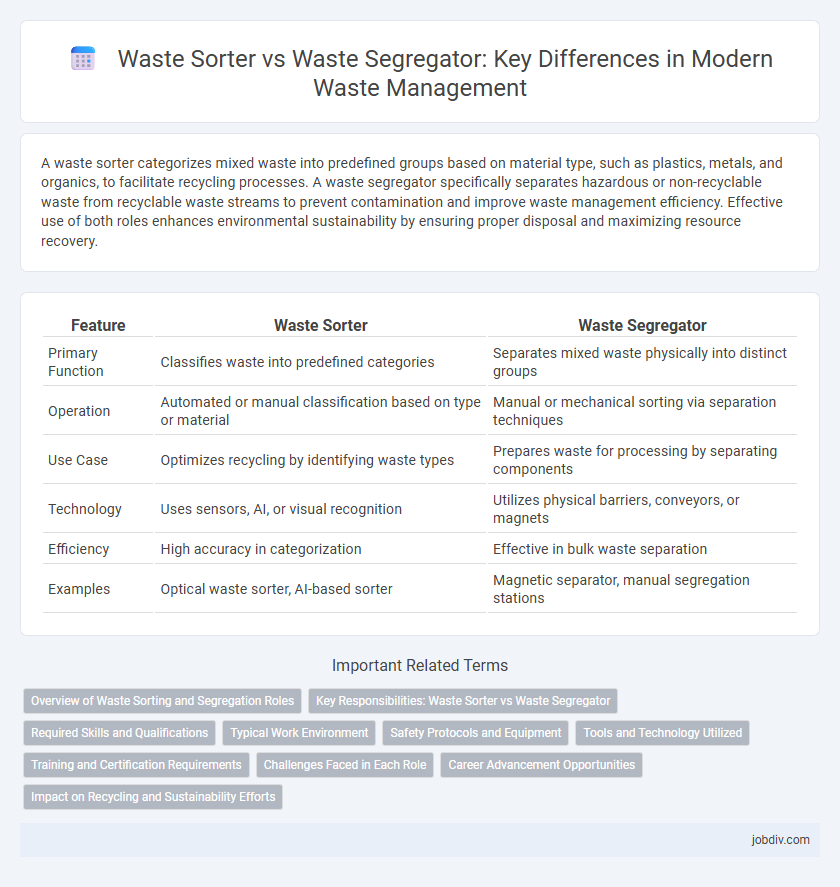

A waste sorter categorizes mixed waste into predefined groups based on material type, such as plastics, metals, and organics, to facilitate recycling processes. A waste segregator specifically separates hazardous or non-recyclable waste from recyclable waste streams to prevent contamination and improve waste management efficiency. Effective use of both roles enhances environmental sustainability by ensuring proper disposal and maximizing resource recovery.

Table of Comparison

| Feature | Waste Sorter | Waste Segregator |

|---|---|---|

| Primary Function | Classifies waste into predefined categories | Separates mixed waste physically into distinct groups |

| Operation | Automated or manual classification based on type or material | Manual or mechanical sorting via separation techniques |

| Use Case | Optimizes recycling by identifying waste types | Prepares waste for processing by separating components |

| Technology | Uses sensors, AI, or visual recognition | Utilizes physical barriers, conveyors, or magnets |

| Efficiency | High accuracy in categorization | Effective in bulk waste separation |

| Examples | Optical waste sorter, AI-based sorter | Magnetic separator, manual segregation stations |

Overview of Waste Sorting and Segregation Roles

Waste sorting involves categorizing waste materials based on their type, such as plastics, metals, and organics, typically at the source or collection point to facilitate recycling and disposal. Waste segregation refers to the systematic separation of waste into distinct streams to prevent contamination and improve treatment efficiency, often guided by legal regulations and environmental standards. Both roles are critical in enhancing waste management processes, reducing landfill use, and promoting resource recovery.

Key Responsibilities: Waste Sorter vs Waste Segregator

Waste sorters primarily focus on manually separating recyclable materials such as plastics, metals, and paper from general waste to reduce landfill volume and improve recycling efficiency. Waste segregators are responsible for categorizing waste based on type, hazard level, and recyclability at the source or facility, ensuring compliance with environmental regulations and facilitating proper disposal or processing. Both roles contribute to waste management systems, but sorters emphasize material recovery, while segregators prioritize classification and compliance.

Required Skills and Qualifications

Waste sorters require basic skills such as manual dexterity, attention to detail, and the ability to identify recyclable materials, often needing only minimal formal education or on-the-job training. Waste segregators typically possess advanced qualifications, including knowledge of environmental regulations, proficiency in using sorting machinery, and a background in waste management or environmental science. Both roles demand strong organizational skills and a commitment to safety protocols to ensure efficient and compliant waste processing.

Typical Work Environment

Waste sorters typically operate in recycling facilities, landfill sites, or waste transfer stations where they manually or mechanically separate materials based on type, such as plastics, metals, and paper, often in noisy and dusty conditions. Waste segregators usually work closer to the source, such as residential or commercial buildings, sorting waste streams into categories like organic, recyclable, and non-recyclable, often in controlled indoor environments. Both roles require adherence to safety protocols due to exposure to hazardous materials and fluctuating environmental conditions.

Safety Protocols and Equipment

Waste sorters use manual or semi-automated methods to separate recyclable and non-recyclable materials, requiring personal protective equipment (PPE) such as gloves, masks, and safety goggles to minimize exposure to hazardous substances. Waste segregators typically operate in automated or mechanized systems with advanced safety protocols, including machine guards, emergency stop controls, and sensor-based hazard detection to prevent accidents. Both roles emphasize strict adherence to workplace safety standards established by OSHA and ISO to ensure efficient handling and reduced risk of contamination or injury.

Tools and Technology Utilized

Waste sorters typically rely on manual tools such as handheld scanners, magnetic separators, and conveyor belts integrated with optical sensors to identify and categorize recyclable materials efficiently. Waste segregators utilize advanced technologies including automated robotic arms, AI-powered vision systems, and smart bins equipped with IoT sensors to sort waste at the source with higher precision and real-time data monitoring. Both systems increasingly incorporate machine learning algorithms to enhance accuracy and streamline the waste management process, reducing contamination and improving recycling rates.

Training and Certification Requirements

Waste sorters require hands-on training in identifying and separating recyclable materials, organic waste, and hazardous substances to ensure proper disposal and environmental safety. Waste segregators must complete certification programs emphasizing regulatory compliance, waste management protocols, and advanced sorting techniques to handle diverse waste streams effectively. Both roles demand ongoing education to stay updated with evolving waste management standards and technologies.

Challenges Faced in Each Role

Waste sorters face challenges such as inconsistent waste streams, physical strain from manual sorting, and exposure to hazardous materials. Waste segregators encounter difficulties in accurately identifying and separating diverse waste types while ensuring compliance with environmental regulations. Both roles demand specialized training and robust safety measures to mitigate health risks and improve efficiency.

Career Advancement Opportunities

Career advancement opportunities in waste management differ between waste sorters and waste segregators due to the varying skill sets required. Waste sorters often develop operational expertise in material handling, increasing their potential for roles in logistics or facility supervision. Waste segregators acquire knowledge in contamination control and recycling processes, paving the way towards environmental compliance and waste management specialist positions.

Impact on Recycling and Sustainability Efforts

Waste sorters improve recycling efficiency by manually separating materials based on type, reducing contamination and enhancing the quality of recyclables. Waste segregators, often automated systems, enable more precise and large-scale separation of waste streams, boosting sustainability efforts by minimizing landfill dependence and optimizing resource recovery. Both technologies contribute significantly to circular economy goals by promoting higher recycling rates and lowering environmental footprints.

Waste Sorter vs Waste Segregator Infographic

jobdiv.com

jobdiv.com