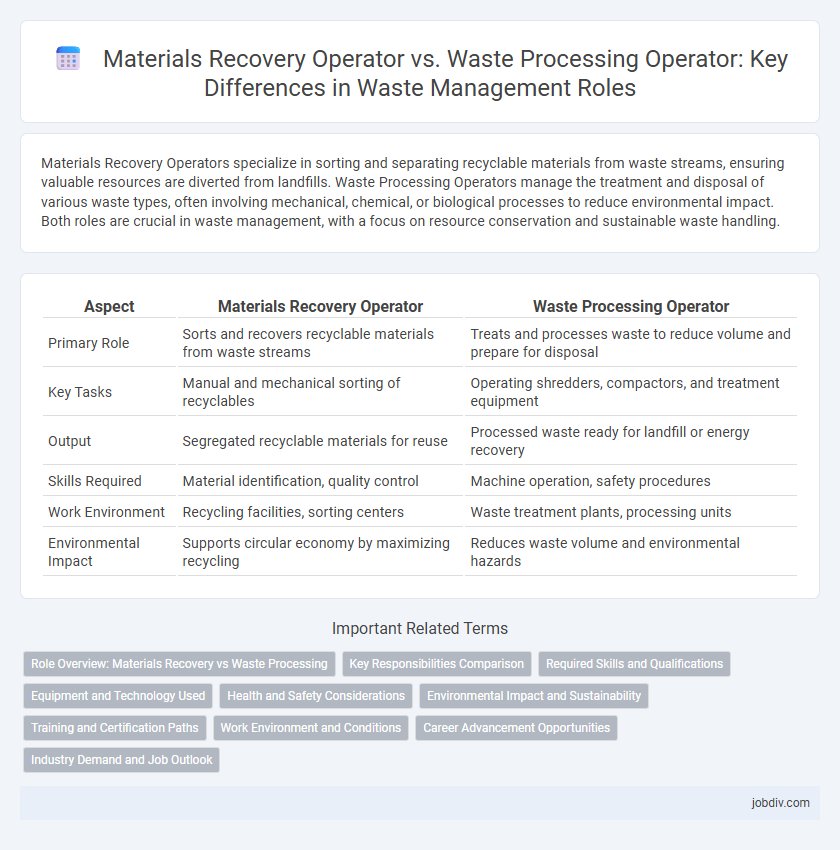

Materials Recovery Operators specialize in sorting and separating recyclable materials from waste streams, ensuring valuable resources are diverted from landfills. Waste Processing Operators manage the treatment and disposal of various waste types, often involving mechanical, chemical, or biological processes to reduce environmental impact. Both roles are crucial in waste management, with a focus on resource conservation and sustainable waste handling.

Table of Comparison

| Aspect | Materials Recovery Operator | Waste Processing Operator |

|---|---|---|

| Primary Role | Sorts and recovers recyclable materials from waste streams | Treats and processes waste to reduce volume and prepare for disposal |

| Key Tasks | Manual and mechanical sorting of recyclables | Operating shredders, compactors, and treatment equipment |

| Output | Segregated recyclable materials for reuse | Processed waste ready for landfill or energy recovery |

| Skills Required | Material identification, quality control | Machine operation, safety procedures |

| Work Environment | Recycling facilities, sorting centers | Waste treatment plants, processing units |

| Environmental Impact | Supports circular economy by maximizing recycling | Reduces waste volume and environmental hazards |

Role Overview: Materials Recovery vs Waste Processing

Materials Recovery Operators specialize in sorting, separating, and preparing recyclable materials for further processing, ensuring efficient recovery of valuable resources. Waste Processing Operators manage the treatment and disposal of waste by operating machinery that processes solid, liquid, or hazardous waste to reduce environmental impact. Both roles are critical in waste management, with Materials Recovery focusing on resource reclamation and Waste Processing emphasizing waste reduction and safe handling.

Key Responsibilities Comparison

Materials Recovery Operators specialize in sorting and separating recyclable materials from waste streams to maximize material recovery efficiency and ensure compliance with environmental regulations. Waste Processing Operators focus on the handling, treatment, and disposal of waste, including shredding, compacting, and preparing waste for landfill or energy recovery. Both roles require adherence to safety protocols and operational standards, but Materials Recovery Operators emphasize resource extraction while Waste Processing Operators concentrate on waste transformation and final disposal methods.

Required Skills and Qualifications

Materials Recovery Operators must possess strong sorting and identification skills to efficiently separate recyclable materials, with certifications in hazardous materials handling often preferred. Waste Processing Operators require knowledge of mechanical and chemical waste treatment processes, along with certifications in equipment operation and environmental safety standards. Both roles demand physical stamina, attention to detail, and adherence to regulatory compliance for safe and effective waste management.

Equipment and Technology Used

Materials Recovery Operators utilize advanced sorting equipment such as conveyor belts, magnetic separators, and optical sorters to efficiently separate recyclable materials from waste streams. Waste Processing Operators often work with shredders, compactors, and anaerobic digesters to break down and treat waste for disposal or energy recovery. Both roles employ technology designed to enhance waste diversion, improve material quality, and optimize overall processing efficiency.

Health and Safety Considerations

Materials Recovery Operators and Waste Processing Operators face distinct health and safety challenges due to the nature of their tasks; Materials Recovery Operators primarily sort recyclables, exposing them to sharp objects and biohazards that require stringent personal protective equipment (PPE) and ergonomic measures. Waste Processing Operators handle more mechanically intensive operations, such as compacting and shredding waste, which demands rigorous machine guarding, lockout/tagout procedures, and continuous monitoring of noise and dust levels. Both roles necessitate comprehensive training in hazard identification, respiratory protection, and compliance with Occupational Safety and Health Administration (OSHA) standards to mitigate risks of injury and long-term health issues.

Environmental Impact and Sustainability

Materials Recovery Operators enhance environmental sustainability by efficiently sorting recyclable materials, reducing landfill waste, and conserving natural resources through high recovery rates. Waste Processing Operators manage the treatment and disposal of waste, focusing on minimizing pollution and enabling energy recovery through technologies like incineration and anaerobic digestion. Both roles contribute to waste management systems, but Materials Recovery Operators have a more direct impact on sustainability by promoting circular economy principles and reducing raw material extraction.

Training and Certification Paths

Materials Recovery Operators require specialized training in sorting techniques, contamination identification, and machinery operation to efficiently separate recyclable materials. Waste Processing Operators undergo certification in waste treatment technologies, environmental regulations, and safety protocols to manage organic and hazardous waste streams. Both roles demand adherence to regulatory standards, but Materials Recovery Operator training prioritizes material classification, while Waste Processing Operator programs emphasize treatment and disposal processes.

Work Environment and Conditions

Materials Recovery Operators typically work in recycling facilities where controlled environments maintain safety from hazardous waste, often involving sorting recyclable materials on conveyor belts with protective gear. Waste Processing Operators generally operate in larger waste treatment plants or landfills, exposing them to more variable outdoor conditions and potential exposure to organic waste, requiring robust safety protocols and physical endurance. Both roles demand adherence to environmental regulations and effective handling of waste to minimize environmental impact.

Career Advancement Opportunities

Materials Recovery Operators specialize in sorting recyclables to maximize resource reclamation, gaining expertise that supports progression into supervisory roles or environmental quality control. Waste Processing Operators handle the treatment and disposal of various waste streams, with career advancement pathways leading to plant management or regulatory compliance positions. Both roles offer distinct opportunities for skill development, with Materials Recovery focusing on sustainability initiatives and Waste Processing emphasizing operational efficiency.

Industry Demand and Job Outlook

The demand for Materials Recovery Operators is rising due to increased recycling initiatives and stricter environmental regulations, emphasizing the need for skilled professionals in sorting and processing recyclable materials. Waste Processing Operators remain essential with steady job growth projected as waste management facilities expand to handle diverse waste streams, incorporating advanced technologies. Both roles require adherence to safety standards and efficiency, but Materials Recovery Operators face higher demand in regions prioritizing circular economy practices.

Materials Recovery Operator vs Waste Processing Operator Infographic

jobdiv.com

jobdiv.com