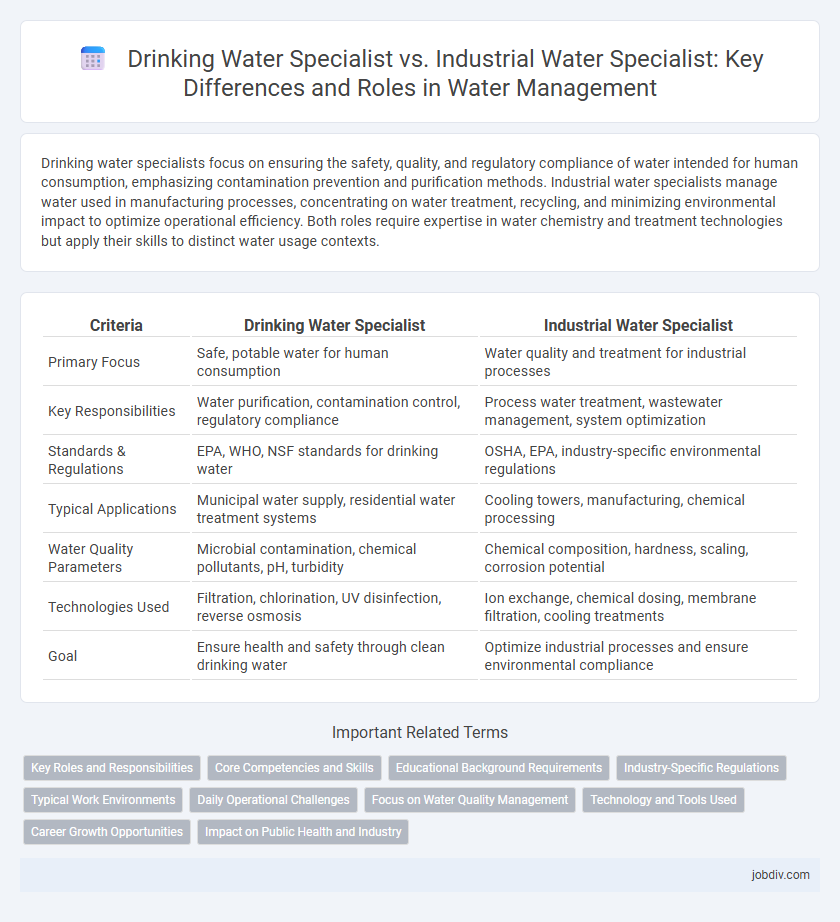

Drinking water specialists focus on ensuring the safety, quality, and regulatory compliance of water intended for human consumption, emphasizing contamination prevention and purification methods. Industrial water specialists manage water used in manufacturing processes, concentrating on water treatment, recycling, and minimizing environmental impact to optimize operational efficiency. Both roles require expertise in water chemistry and treatment technologies but apply their skills to distinct water usage contexts.

Table of Comparison

| Criteria | Drinking Water Specialist | Industrial Water Specialist |

|---|---|---|

| Primary Focus | Safe, potable water for human consumption | Water quality and treatment for industrial processes |

| Key Responsibilities | Water purification, contamination control, regulatory compliance | Process water treatment, wastewater management, system optimization |

| Standards & Regulations | EPA, WHO, NSF standards for drinking water | OSHA, EPA, industry-specific environmental regulations |

| Typical Applications | Municipal water supply, residential water treatment systems | Cooling towers, manufacturing, chemical processing |

| Water Quality Parameters | Microbial contamination, chemical pollutants, pH, turbidity | Chemical composition, hardness, scaling, corrosion potential |

| Technologies Used | Filtration, chlorination, UV disinfection, reverse osmosis | Ion exchange, chemical dosing, membrane filtration, cooling treatments |

| Goal | Ensure health and safety through clean drinking water | Optimize industrial processes and ensure environmental compliance |

Key Roles and Responsibilities

Drinking Water Specialists focus on ensuring the safety, quality, and regulatory compliance of potable water systems, conducting water quality testing, treatment assessments, and public health risk evaluations. Industrial Water Specialists manage the use and treatment of water in manufacturing and industrial processes, optimizing water recycling, minimizing waste discharge, and maintaining system efficiency to meet environmental standards. Both roles require expertise in water chemistry, treatment technologies, and adherence to local and international water quality regulations.

Core Competencies and Skills

Drinking Water Specialists excel in water quality analysis, regulatory compliance with EPA standards, and contamination prevention to ensure safe public consumption. Industrial Water Specialists focus on system optimization, wastewater treatment, and scaling prevention to support manufacturing processes and equipment longevity. Both require expertise in water chemistry and treatment technologies but apply these skills toward distinct operational goals.

Educational Background Requirements

Drinking water specialists typically require a background in environmental science, public health, or chemistry with an emphasis on water quality and regulatory compliance. Industrial water specialists often have degrees in chemical engineering, industrial engineering, or environmental engineering, focusing on water treatment processes and industrial system management. Both roles demand expertise in water treatment technologies but differ in their applied educational emphasis, reflecting the distinct operational environments they serve.

Industry-Specific Regulations

Drinking water specialists ensure compliance with stringent health and safety standards set by agencies like the EPA and WHO, focusing on contamination limits and potable water quality. Industrial water specialists navigate regulations such as the Clean Water Act and local discharge permits, addressing effluent treatment and water reuse requirements specific to manufacturing and processing industries. Both roles require expertise in regulatory frameworks but prioritize different water quality parameters to meet industry-specific environmental and public health standards.

Typical Work Environments

Drinking water specialists primarily work in municipal water treatment plants, laboratories, and regulatory agencies ensuring safe and potable water for public consumption. Industrial water specialists are often found in manufacturing facilities, power plants, and chemical processing industries focusing on water usage, treatment, and discharge for operational processes. Both roles require expertise in water quality management but differ significantly in their typical work environments and regulatory frameworks.

Daily Operational Challenges

Drinking Water Specialists focus on maintaining safe and compliant potable water systems, managing contamination risks, and ensuring regulatory standards for human consumption are consistently met. Industrial Water Specialists address challenges related to process water quality, scaling, corrosion control, and wastewater treatment within manufacturing environments to optimize operational efficiency. Both roles require expertise in water chemistry and system monitoring but differ significantly in the scale and impact of water use on health and industrial processes.

Focus on Water Quality Management

Drinking Water Specialists concentrate on ensuring potable water meets stringent health and safety standards by monitoring contaminants such as lead, bacteria, and chlorine levels. Industrial Water Specialists focus on managing water quality in manufacturing processes, emphasizing the removal of chemical pollutants and maintaining optimal water conditions for equipment efficiency. Both roles require expertise in water treatment technologies and regulatory compliance to safeguard water use in their respective sectors.

Technology and Tools Used

Drinking water specialists utilize advanced filtration systems, UV disinfection, and real-time monitoring sensors to ensure potable water safety and compliance with health standards. Industrial water specialists employ technologies such as chemical dosing systems, reverse osmosis, and automated water treatment plants designed for large-scale water management and process optimization. Both experts rely on specialized software for data analysis and system control to maintain water quality according to their respective regulatory requirements.

Career Growth Opportunities

Drinking water specialists often experience career growth through roles in public health agencies, regulatory compliance, and water quality management, driven by increasing demand for safe potable water. Industrial water specialists tend to advance in sectors like manufacturing, energy, and environmental engineering, focusing on process water treatment, wastewater management, and sustainability initiatives. Both career paths benefit from the expanding global emphasis on water resource management, regulatory standards, and technological innovation in water treatment systems.

Impact on Public Health and Industry

Drinking water specialists ensure the safety and quality of potable water, directly reducing waterborne diseases and safeguarding public health through rigorous testing and treatment protocols. Industrial water specialists focus on managing water used in manufacturing and cooling processes, optimizing efficiency while preventing environmental contamination and minimizing operational hazards. Both roles are critical, with drinking water experts protecting community health and industrial specialists supporting sustainable industrial practices.

Drinking Water Specialist vs Industrial Water Specialist Infographic

jobdiv.com

jobdiv.com