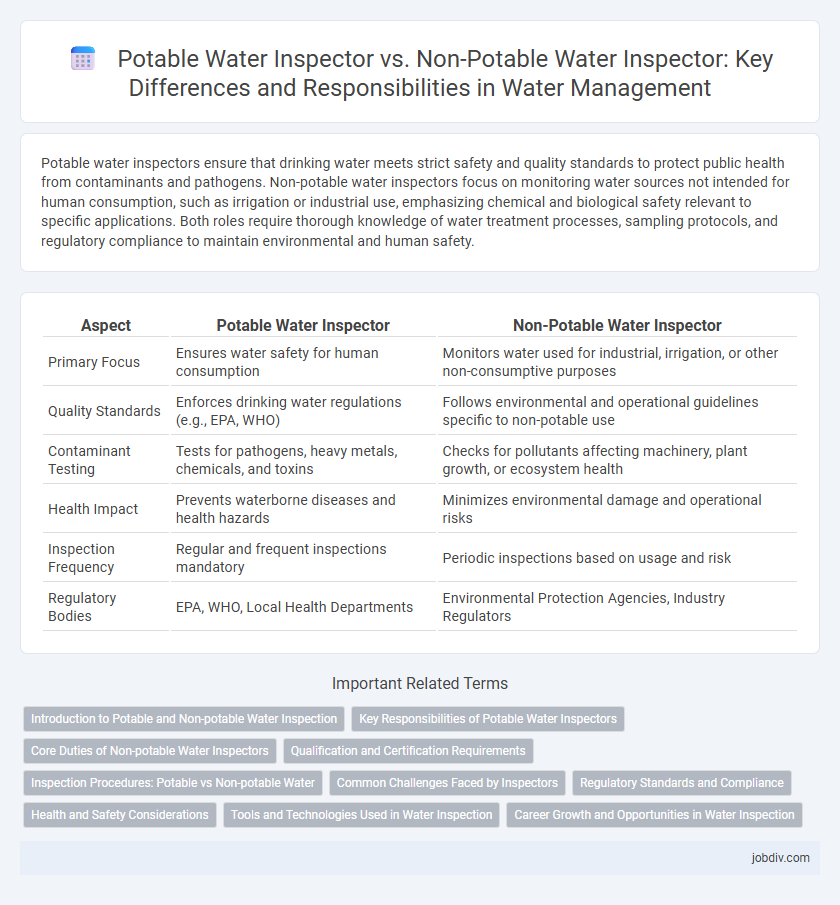

Potable water inspectors ensure that drinking water meets strict safety and quality standards to protect public health from contaminants and pathogens. Non-potable water inspectors focus on monitoring water sources not intended for human consumption, such as irrigation or industrial use, emphasizing chemical and biological safety relevant to specific applications. Both roles require thorough knowledge of water treatment processes, sampling protocols, and regulatory compliance to maintain environmental and human safety.

Table of Comparison

| Aspect | Potable Water Inspector | Non-Potable Water Inspector |

|---|---|---|

| Primary Focus | Ensures water safety for human consumption | Monitors water used for industrial, irrigation, or other non-consumptive purposes |

| Quality Standards | Enforces drinking water regulations (e.g., EPA, WHO) | Follows environmental and operational guidelines specific to non-potable use |

| Contaminant Testing | Tests for pathogens, heavy metals, chemicals, and toxins | Checks for pollutants affecting machinery, plant growth, or ecosystem health |

| Health Impact | Prevents waterborne diseases and health hazards | Minimizes environmental damage and operational risks |

| Inspection Frequency | Regular and frequent inspections mandatory | Periodic inspections based on usage and risk |

| Regulatory Bodies | EPA, WHO, Local Health Departments | Environmental Protection Agencies, Industry Regulators |

Introduction to Potable and Non-potable Water Inspection

Potable water inspectors ensure the safety, quality, and compliance of drinking water sources by testing for contaminants such as bacteria, heavy metals, and chemical pollutants. Non-potable water inspectors focus on water used for irrigation, industrial processes, or sanitation, assessing parameters like turbidity, pH, and biological oxygen demand to prevent health hazards and environmental impact. Both roles require knowledge of water treatment standards, regulatory guidelines, and sampling techniques to maintain public and environmental health.

Key Responsibilities of Potable Water Inspectors

Potable Water Inspectors are responsible for ensuring water safety by regularly testing water quality for contaminants and compliance with health standards mandated by organizations such as the EPA and WHO. They conduct detailed inspections on water treatment facilities, distribution systems, and storage tanks to prevent microbial and chemical hazards. Their key role includes certifying that drinking water meets regulatory requirements to protect public health and prevent waterborne diseases.

Core Duties of Non-potable Water Inspectors

Non-potable water inspectors specialize in monitoring water sources that are not safe for human consumption, ensuring compliance with safety regulations to prevent contamination and environmental hazards. Their core duties include inspecting irrigation systems, industrial water supplies, and wastewater treatment facilities to verify structural integrity, proper chemical usage, and adherence to local water quality standards. They also conduct regular sampling and testing to detect contaminants, mitigating risks associated with non-potable water use in agriculture, manufacturing, and other non-consumptive applications.

Qualification and Certification Requirements

Potable Water Inspectors require certifications such as the NSF/ANSI 600 or Certified Pool Operator (CPO) credentials, along with qualifications in water quality testing and public health standards compliance. Non-potable Water Inspectors typically need expertise in wastewater management and certification from organizations like the American Water Works Association (AWWA) or similar regional authorities. Both roles demand thorough knowledge of regulatory guidelines, but potable water inspectors emphasize drinking water safety, while non-potable inspectors focus on irrigation, industrial applications, or wastewater systems.

Inspection Procedures: Potable vs Non-potable Water

Potable water inspectors conduct rigorous testing for contaminants such as bacteria, heavy metals, and chemical pollutants, ensuring compliance with health and safety standards set by agencies like the EPA and WHO. Non-potable water inspectors focus on evaluating physical characteristics like turbidity, sediment levels, and the presence of non-hazardous organic matter, prioritizing functionality over human consumption safety. Both inspection procedures employ specialized equipment, but potable water mandates frequent microbial analysis, whereas non-potable inspections emphasize system integrity and usability in irrigation or industrial applications.

Common Challenges Faced by Inspectors

Potable water inspectors and non-potable water inspectors both face challenges such as detecting microbial contamination and ensuring compliance with regulatory standards. Potable water inspectors must prioritize preventing health risks related to drinking water safety, while non-potable inspectors deal with broader issues like chemical pollutants and system integrity. Both roles require precise sampling techniques, accurate data analysis, and effective communication with stakeholders to maintain water quality.

Regulatory Standards and Compliance

Potable water inspectors ensure compliance with strict regulatory standards such as the Safe Drinking Water Act (SDWA) and EPA guidelines, verifying that water meets health-based quality criteria for human consumption. Non-potable water inspectors focus on regulations related to industrial or irrigation water, which often require adherence to environmental discharge permits and non-health-based standards. Both types of inspectors conduct systematic testing and documentation to maintain compliance and protect public and environmental safety.

Health and Safety Considerations

Potable water inspectors ensure water meets strict health standards by testing for contaminants such as bacteria, heavy metals, and chemicals to prevent waterborne diseases, while non-potable water inspectors focus on monitoring water quality used in industrial or irrigation applications where human consumption is not intended. Health and safety considerations for potable water emphasize compliance with regulations from agencies like the EPA and WHO to guarantee safe drinking water, whereas non-potable water inspections prioritize preventing cross-contamination and environmental pollution. Effective inspection protocols reduce public health risks by maintaining water quality tailored to specific usage standards.

Tools and Technologies Used in Water Inspection

Potable water inspectors utilize advanced technologies such as turbidity meters, microbial test kits, and chemical analyzers to ensure water meets health and safety standards for human consumption. Non-potable water inspectors rely more on equipment like pH meters, conductivity probes, and visual inspection tools to assess water quality for industrial or agricultural use without strict potable standards. Both roles integrate GPS mapping and remote sensing technologies to enhance inspection accuracy and data collection efficiency.

Career Growth and Opportunities in Water Inspection

Potable water inspectors specialize in ensuring safe drinking water quality, offering career growth through roles in public health agencies, municipalities, and environmental consulting firms. Non-potable water inspectors focus on water used for irrigation, industrial processes, or firefighting, with opportunities concentrated in agricultural sectors, manufacturing, and waste management industries. Both paths provide advancement via certifications and expertise, but potable water inspection typically offers broader regulatory impact and higher demand due to public health priorities.

Potable Water Inspector vs Non-potable Water Inspector Infographic

jobdiv.com

jobdiv.com