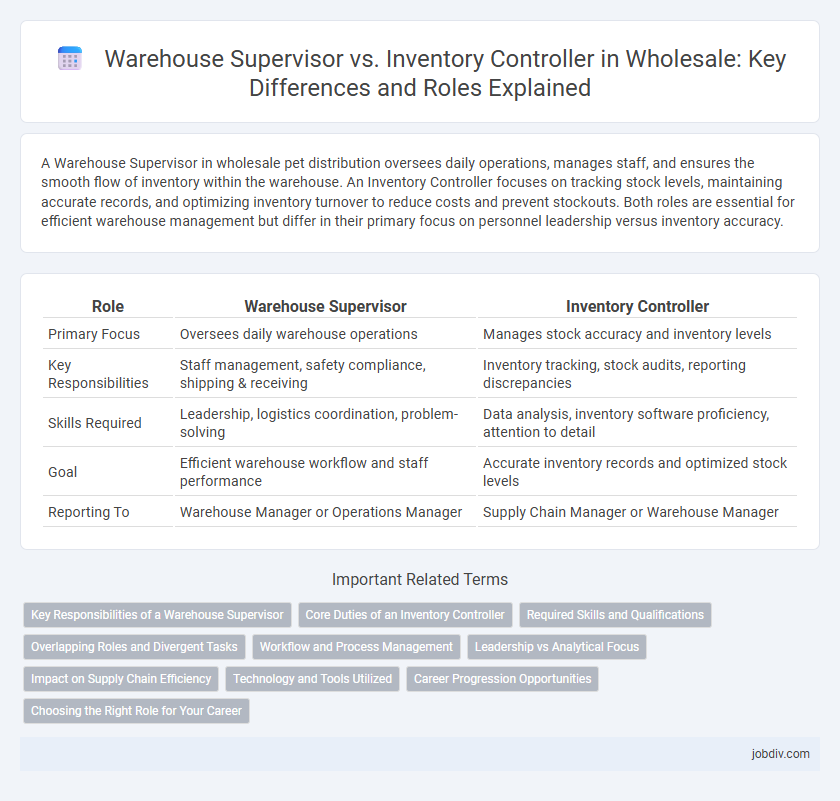

A Warehouse Supervisor in wholesale pet distribution oversees daily operations, manages staff, and ensures the smooth flow of inventory within the warehouse. An Inventory Controller focuses on tracking stock levels, maintaining accurate records, and optimizing inventory turnover to reduce costs and prevent stockouts. Both roles are essential for efficient warehouse management but differ in their primary focus on personnel leadership versus inventory accuracy.

Table of Comparison

| Role | Warehouse Supervisor | Inventory Controller |

|---|---|---|

| Primary Focus | Oversees daily warehouse operations | Manages stock accuracy and inventory levels |

| Key Responsibilities | Staff management, safety compliance, shipping & receiving | Inventory tracking, stock audits, reporting discrepancies |

| Skills Required | Leadership, logistics coordination, problem-solving | Data analysis, inventory software proficiency, attention to detail |

| Goal | Efficient warehouse workflow and staff performance | Accurate inventory records and optimized stock levels |

| Reporting To | Warehouse Manager or Operations Manager | Supply Chain Manager or Warehouse Manager |

Key Responsibilities of a Warehouse Supervisor

A Warehouse Supervisor primarily oversees daily warehouse operations, ensuring efficient receipt, storage, and dispatch of goods while maintaining safety standards and staff productivity. They coordinate team activities, manage inventory accuracy through regular audits, and implement warehouse management systems to optimize workflow. Unlike an Inventory Controller, whose focus is on stock levels, order fulfillment, and inventory reporting, the Warehouse Supervisor directly manages physical operations and workforce coordination within the warehouse environment.

Core Duties of an Inventory Controller

An Inventory Controller in wholesale primarily manages stock levels by conducting regular audits, analyzing inventory data, and forecasting demand to prevent shortages or excess. Their core duties include maintaining accurate inventory records, coordinating with purchasing and warehouse teams, and implementing inventory control systems to optimize stock flow. This role focuses on accuracy and efficiency in stock management, contrasting with a Warehouse Supervisor who oversees daily warehouse operations and staff management.

Required Skills and Qualifications

Warehouse Supervisors require strong leadership skills, experience in warehouse management systems, and proficiency in safety compliance and team coordination. Inventory Controllers must have expertise in stock management, data analysis, and proficiency with inventory software such as ERP systems. Both roles demand attention to detail, problem-solving abilities, and familiarity with supply chain processes in the wholesale industry.

Overlapping Roles and Divergent Tasks

Warehouse Supervisors oversee daily operations, staff management, and shipment coordination to ensure efficient workflow within wholesale distribution centers. Inventory Controllers focus on stock accuracy, order forecasting, and inventory reconciliation to maintain optimal product levels and minimize discrepancies. Both roles collaborate on inventory tracking and quality control but diverge in operational leadership versus data-driven stock management responsibilities.

Workflow and Process Management

Warehouse Supervisors manage overall warehouse operations, focusing on workflow efficiency, staff coordination, and safety compliance to ensure smooth receipt, storage, and dispatch of goods. Inventory Controllers specialize in tracking stock levels, performing regular audits, and maintaining accurate inventory records to prevent discrepancies and optimize stock availability. Both roles require strong process management skills, with Warehouse Supervisors overseeing physical space and movement, while Inventory Controllers focus on data accuracy and inventory flow within the wholesale supply chain.

Leadership vs Analytical Focus

Warehouse Supervisors excel in leadership by managing teams, coordinating daily operations, and ensuring efficient workflow within wholesale warehouses. Inventory Controllers prioritize analytical skills, focusing on accurate stock monitoring, data analysis, and optimizing inventory levels to reduce costs and prevent shortages. Balancing leadership with analytical expertise drives operational success in wholesale supply chain management.

Impact on Supply Chain Efficiency

Warehouse Supervisors directly influence supply chain efficiency by managing daily operations, workforce productivity, and ensuring timely order fulfillment. Inventory Controllers optimize stock levels, reduce holding costs, and prevent stockouts or overstock situations through precise inventory tracking and demand forecasting. Coordinated efforts between these roles enhance overall supply chain performance by minimizing delays and improving inventory accuracy.

Technology and Tools Utilized

Warehouse supervisors utilize advanced warehouse management systems (WMS) and automated tracking technologies such as barcode scanners and RFID to streamline operations and manage labor schedules effectively. Inventory controllers leverage inventory optimization software, demand forecasting tools, and real-time data analytics platforms to maintain stock accuracy and reduce carrying costs. Both roles increasingly integrate cloud-based solutions and IoT devices to enhance visibility and coordination across the supply chain.

Career Progression Opportunities

A Warehouse Supervisor often advances toward roles such as Operations Manager or Logistics Coordinator, leveraging hands-on experience in managing warehouse activities and team oversight. An Inventory Controller typically progresses to Supply Chain Analyst or Inventory Manager positions, capitalizing on skills in data analysis and stock optimization. Both career paths offer distinct opportunities within wholesale logistics, with Supervisors focusing on operational leadership and Controllers on strategic inventory management.

Choosing the Right Role for Your Career

Warehouse Supervisors oversee daily operations, manage staff, and ensure timely shipping and receiving, requiring strong leadership and logistical skills. Inventory Controllers specialize in monitoring stock levels, conducting audits, and optimizing supply chain accuracy through data analysis and inventory software proficiency. Selecting the right role depends on your preference for hands-on team management or detailed inventory accuracy to align with career growth in wholesale.

Warehouse Supervisor vs Inventory Controller Infographic

jobdiv.com

jobdiv.com