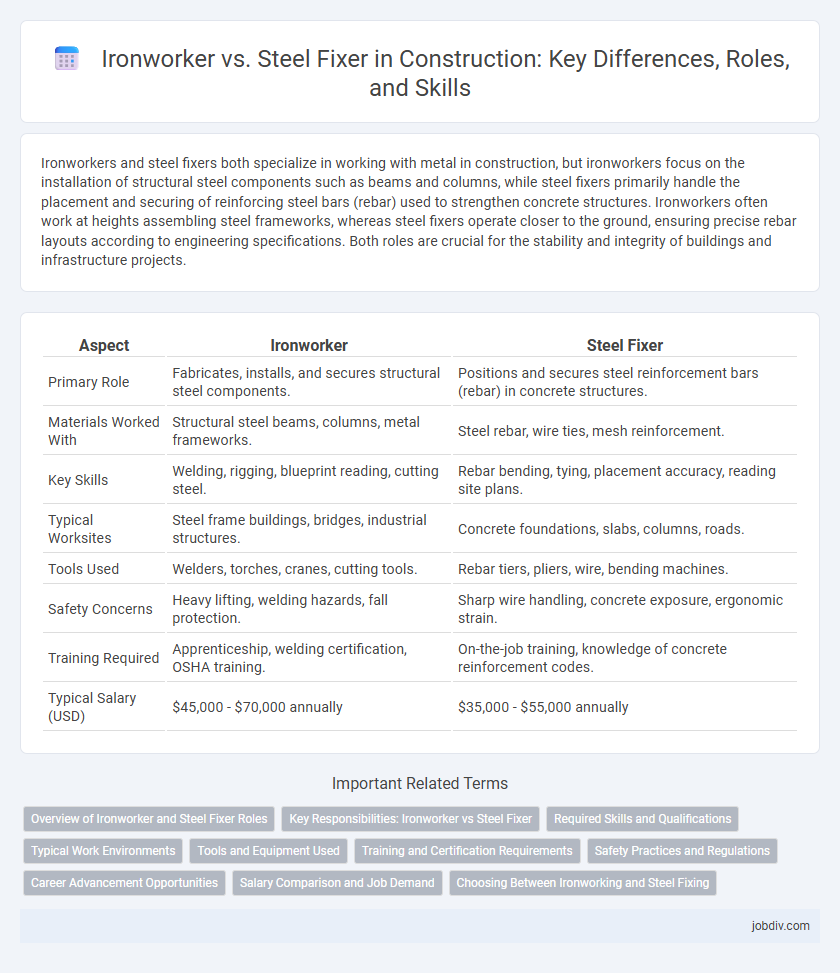

Ironworkers and steel fixers both specialize in working with metal in construction, but ironworkers focus on the installation of structural steel components such as beams and columns, while steel fixers primarily handle the placement and securing of reinforcing steel bars (rebar) used to strengthen concrete structures. Ironworkers often work at heights assembling steel frameworks, whereas steel fixers operate closer to the ground, ensuring precise rebar layouts according to engineering specifications. Both roles are crucial for the stability and integrity of buildings and infrastructure projects.

Table of Comparison

| Aspect | Ironworker | Steel Fixer |

|---|---|---|

| Primary Role | Fabricates, installs, and secures structural steel components. | Positions and secures steel reinforcement bars (rebar) in concrete structures. |

| Materials Worked With | Structural steel beams, columns, metal frameworks. | Steel rebar, wire ties, mesh reinforcement. |

| Key Skills | Welding, rigging, blueprint reading, cutting steel. | Rebar bending, tying, placement accuracy, reading site plans. |

| Typical Worksites | Steel frame buildings, bridges, industrial structures. | Concrete foundations, slabs, columns, roads. |

| Tools Used | Welders, torches, cranes, cutting tools. | Rebar tiers, pliers, wire, bending machines. |

| Safety Concerns | Heavy lifting, welding hazards, fall protection. | Sharp wire handling, concrete exposure, ergonomic strain. |

| Training Required | Apprenticeship, welding certification, OSHA training. | On-the-job training, knowledge of concrete reinforcement codes. |

| Typical Salary (USD) | $45,000 - $70,000 annually | $35,000 - $55,000 annually |

Overview of Ironworker and Steel Fixer Roles

Ironworkers specialize in installing structural steel frameworks for buildings, bridges, and other infrastructure, ensuring the stability and safety of the construction. Steel fixers focus on placing and securing steel reinforcement bars (rebar) within concrete forms to enhance the strength and durability of concrete structures. Both roles require precision and knowledge of blueprints but differ in their specific tasks and materials handled on construction sites.

Key Responsibilities: Ironworker vs Steel Fixer

Ironworkers primarily focus on installing and securing structural steel frameworks, including beams, columns, and girders, ensuring the stability of buildings and bridges. Steel fixers specialize in positioning and fastening steel reinforcement bars (rebar) used to strengthen concrete structures, often working from detailed engineering drawings. Both roles require precise measurement and adherence to safety standards, but ironworkers handle larger steel assemblies while steel fixers concentrate on reinforcing concrete elements.

Required Skills and Qualifications

Ironworkers require advanced proficiency in interpreting blueprints, welding, and operating heavy machinery to install structural steel frameworks. Steel fixers must excel in reading construction drawings, precise measurement, and tying steel reinforcement bars to ensure concrete structure stability. Both roles demand strong physical stamina, adherence to safety regulations, and relevant certifications such as OSHA safety training and NCCER steel-related qualifications.

Typical Work Environments

Ironworkers commonly operate on large-scale construction sites such as commercial buildings, bridges, and industrial plants, often working at significant heights and in outdoor environments exposed to varying weather conditions. Steel fixers primarily work on concrete construction projects like foundations, tunnels, and highways, focusing on installing reinforcement bars within confined spaces or underground settings. Both roles require strict adherence to safety protocols, but ironworkers face more exposure to elevated risks due to the nature of steel framework assembly.

Tools and Equipment Used

Ironworkers primarily use tools such as welding machines, rebar tying guns, and cutting torches to fabricate and install structural steel frameworks. Steel fixers rely heavily on wire mesh cutters, pliers, and tying tools to position and secure steel reinforcement bars in concrete construction. Both trades require safety equipment like helmets, gloves, and harnesses to ensure protection while working at heights or around heavy materials.

Training and Certification Requirements

Ironworkers require specialized training in structural steel installation, often completing apprenticeships regulated by unions such as the International Association of Bridge, Structural, Ornamental, and Reinforcing Ironworkers (IW). Steel fixers typically undergo vocational training focused on reading blueprints and placing rebar accurately, with certification programs like the Reinforcing Steel Institute of Canada's (RSIC) certification enhancing their qualifications. Both roles may require safety certifications such as OSHA 10 or OSHA 30 to comply with workplace safety standards in construction environments.

Safety Practices and Regulations

Ironworkers and steel fixers both adhere to strict safety practices and regulations mandated by OSHA and industry standards to minimize risks on construction sites. Personal protective equipment (PPE) such as hard hats, gloves, harnesses for fall protection, and steel-toe boots are essential for preventing injuries while handling heavy steel materials and working at heights. Compliance with safety protocols includes rigorous training in hazard recognition, proper use of tools, and secure anchoring techniques to ensure safe installation and reinforcing of steel frameworks.

Career Advancement Opportunities

Ironworkers often have broader career advancement opportunities due to their ability to work on diverse steel structures, including bridges and high-rise buildings, allowing for specialization in welding, rigging, or steel erection supervision. Steel fixers primarily focus on reinforcing concrete with rebar, which can lead to supervisory roles or project management within concrete-focused construction projects but may have narrower specialization paths. Both trades offer pathways to certifications and leadership roles, though ironworkers typically experience more varied project exposure, enhancing overall career growth potential.

Salary Comparison and Job Demand

Ironworkers typically earn between $50,000 and $70,000 annually, whereas steel fixers' salaries range from $45,000 to $65,000, depending on experience and location. The demand for ironworkers is higher in large-scale commercial and infrastructure projects, while steel fixers are essential in residential and smaller industrial constructions. Both roles experience consistent job growth, but ironworkers benefit from broader opportunities and slightly better wages.

Choosing Between Ironworking and Steel Fixing

Choosing between ironworking and steel fixing depends on the specific demands of the construction project and skill preferences. Ironworkers specialize in installing structural steel frameworks and metal components, requiring proficiency in welding and rigging, while steel fixers focus on positioning and securing reinforcing bars (rebar) to strengthen concrete structures, emphasizing precision and layout skills. Project timelines, safety requirements, and the type of materials used influence the decision, making understanding both roles essential for efficient construction management.

Ironworker vs Steel Fixer Infographic

jobdiv.com

jobdiv.com