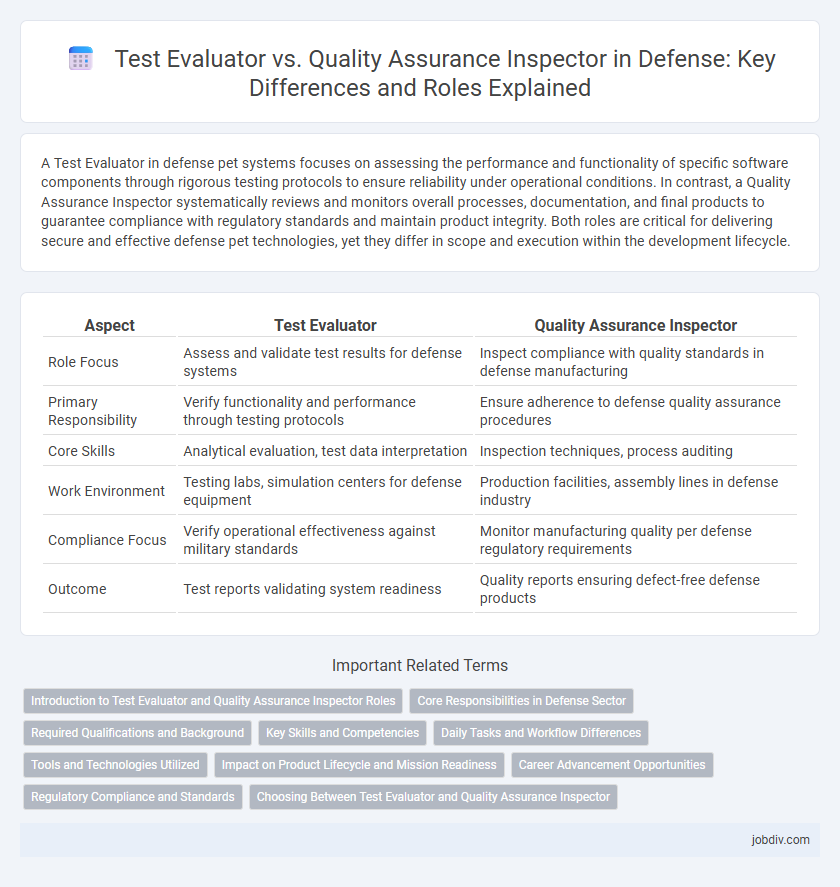

A Test Evaluator in defense pet systems focuses on assessing the performance and functionality of specific software components through rigorous testing protocols to ensure reliability under operational conditions. In contrast, a Quality Assurance Inspector systematically reviews and monitors overall processes, documentation, and final products to guarantee compliance with regulatory standards and maintain product integrity. Both roles are critical for delivering secure and effective defense pet technologies, yet they differ in scope and execution within the development lifecycle.

Table of Comparison

| Aspect | Test Evaluator | Quality Assurance Inspector |

|---|---|---|

| Role Focus | Assess and validate test results for defense systems | Inspect compliance with quality standards in defense manufacturing |

| Primary Responsibility | Verify functionality and performance through testing protocols | Ensure adherence to defense quality assurance procedures |

| Core Skills | Analytical evaluation, test data interpretation | Inspection techniques, process auditing |

| Work Environment | Testing labs, simulation centers for defense equipment | Production facilities, assembly lines in defense industry |

| Compliance Focus | Verify operational effectiveness against military standards | Monitor manufacturing quality per defense regulatory requirements |

| Outcome | Test reports validating system readiness | Quality reports ensuring defect-free defense products |

Introduction to Test Evaluator and Quality Assurance Inspector Roles

Test Evaluators in defense rigorously assess military systems and equipment to verify performance standards and mission readiness, ensuring compliance with technical specifications and operational requirements. Quality Assurance Inspectors focus on inspecting materials, processes, and final products to guarantee adherence to military quality standards and regulatory guidelines throughout production and maintenance phases. Both roles are critical for maintaining defense system reliability, safety, and effectiveness under stringent quality control frameworks.

Core Responsibilities in Defense Sector

A Test Evaluator in the defense sector primarily focuses on assessing weapon systems, software, and equipment through rigorous testing protocols to ensure performance meets military specifications. Quality Assurance Inspectors concentrate on verifying compliance with defense manufacturing standards, inspecting materials, and monitoring production processes to prevent defects in defense hardware. Both roles are critical to maintaining operational readiness and ensuring that defense products meet stringent safety and reliability criteria.

Required Qualifications and Background

Test Evaluators in defense require a strong background in systems engineering, electronics, or aerospace, often holding certifications like ASQ Certified Test Engineer and possessing experience with military standards such as MIL-STD-810. Quality Assurance Inspectors must demonstrate expertise in inspection techniques, quality control processes, and regulatory compliance, frequently requiring certifications like ASQ Certified Quality Inspector and familiarity with ISO 9001 or AS9100 standards. Both roles demand proficiency in technical documentation, problem-solving skills, and the ability to interpret complex defense specifications to ensure product reliability and operational safety.

Key Skills and Competencies

Test Evaluators in defense specialize in analyzing system performance and validating compliance through rigorous data interpretation and analytical skills, ensuring operational reliability. Quality Assurance Inspectors focus on meticulous inspection, defect identification, and adherence to defense industry standards, emphasizing attention to detail and regulatory knowledge. Both roles require strong problem-solving abilities and a profound understanding of defense protocols but differ in their emphasis on evaluation versus inspection.

Daily Tasks and Workflow Differences

Test Evaluators in defense primarily conduct functional and performance tests on weapons systems, ensuring compliance with military specifications through data analysis and reporting. Quality Assurance Inspectors focus on inspecting manufacturing processes, materials, and final products, verifying adherence to defense standards and quality protocols on a daily basis. While Test Evaluators emphasize data-driven validation of system capabilities, Quality Assurance Inspectors concentrate on process control and defect identification during production.

Tools and Technologies Utilized

Test Evaluators in defense employ advanced simulation software, automated testing frameworks, and data analytics tools to rigorously assess system performance under varied operational scenarios. Quality Assurance Inspectors utilize specialized inspection devices such as calibrated measurement instruments, non-destructive testing (NDT) equipment, and compliance management software to ensure adherence to military standards and specifications. Both roles integrate secure communication platforms and industry-specific technologies like MIL-STD-810 testing procedures to maintain the integrity and reliability of defense systems.

Impact on Product Lifecycle and Mission Readiness

Test Evaluators identify design flaws and system failures early in the product lifecycle, reducing costly rework and ensuring compliance with mission-critical specifications. Quality Assurance Inspectors verify that manufacturing processes adhere to established standards, securing product reliability and operational readiness for defense missions. Together, their combined efforts enhance overall mission readiness by delivering robust, high-performance defense systems on schedule.

Career Advancement Opportunities

Test Evaluators in defense gain career advancement by specializing in systems analysis and performance validation, often progressing into engineering or project management roles. Quality Assurance Inspectors focus on compliance and process improvement, leading to opportunities in regulatory affairs or quality management leadership positions. Both roles offer pathways to senior technical or supervisory positions, but Test Evaluators typically advance faster in analytical and developmental career tracks.

Regulatory Compliance and Standards

Test Evaluators in defense rigorously assess systems against military specifications to ensure compliance with DoD standards and operational requirements. Quality Assurance Inspectors focus on verifying manufacturing processes and product adherence to regulatory frameworks such as MIL-STD-810 and AS9100, ensuring reliability and safety. Both roles are critical in maintaining defense equipment integrity by enforcing stringent regulatory compliance and quality standards.

Choosing Between Test Evaluator and Quality Assurance Inspector

Choosing between a Test Evaluator and a Quality Assurance Inspector in defense hinges on the role's focus: Test Evaluators specialize in analyzing performance data to validate system capabilities against military specifications, while Quality Assurance Inspectors concentrate on ensuring adherence to manufacturing and procedural standards throughout production. The Test Evaluator's expertise in data-driven assessment supports mission-critical validation phases, whereas the Quality Assurance Inspector emphasizes defect prevention and compliance in operational processes. Selecting the right role depends on whether the priority is technical validation or process integrity within defense project lifecycles.

Test Evaluator vs Quality Assurance Inspector Infographic

jobdiv.com

jobdiv.com