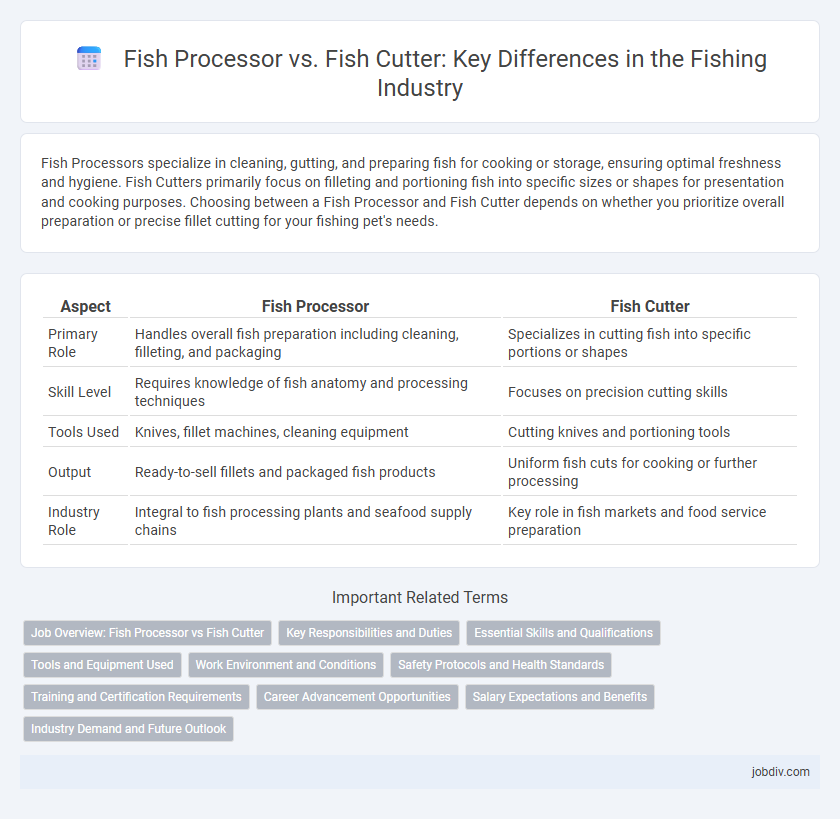

Fish Processors specialize in cleaning, gutting, and preparing fish for cooking or storage, ensuring optimal freshness and hygiene. Fish Cutters primarily focus on filleting and portioning fish into specific sizes or shapes for presentation and cooking purposes. Choosing between a Fish Processor and Fish Cutter depends on whether you prioritize overall preparation or precise fillet cutting for your fishing pet's needs.

Table of Comparison

| Aspect | Fish Processor | Fish Cutter |

|---|---|---|

| Primary Role | Handles overall fish preparation including cleaning, filleting, and packaging | Specializes in cutting fish into specific portions or shapes |

| Skill Level | Requires knowledge of fish anatomy and processing techniques | Focuses on precision cutting skills |

| Tools Used | Knives, fillet machines, cleaning equipment | Cutting knives and portioning tools |

| Output | Ready-to-sell fillets and packaged fish products | Uniform fish cuts for cooking or further processing |

| Industry Role | Integral to fish processing plants and seafood supply chains | Key role in fish markets and food service preparation |

Job Overview: Fish Processor vs Fish Cutter

A fish processor manages the entire post-harvest handling, including cleaning, filleting, packaging, and ensuring quality control to prepare fish for distribution. A fish cutter specializes primarily in the precise cutting and portioning of fish to meet specific product requirements, often working on assembly lines or in processing plants. Both roles require knowledge of safety standards and hygiene but differ in scope, with processors overseeing broader production tasks and cutters focusing on specific cutting techniques.

Key Responsibilities and Duties

Fish processors handle the overall preparation and preservation of fish, including cleaning, filleting, packaging, and ensuring compliance with food safety standards. Fish cutters specialize in precise cutting and portioning of fish specimens to meet specific size, quality, and presentation requirements. Both roles require knowledge of handling fish products, but processors focus more on processing stages while cutters emphasize technical cutting skills.

Essential Skills and Qualifications

Fish processors require strong knowledge of cleaning, gutting, and filleting techniques to maintain product quality and meet safety standards. Fish cutters must possess precise knife skills and physical dexterity to efficiently segment fish while minimizing waste. Both roles demand understanding of hygiene regulations, attention to detail, and the ability to work in cold, fast-paced environments.

Tools and Equipment Used

Fish processors rely on advanced tools such as automatic filleting machines, skinning devices, and high-precision scales to ensure efficient and hygienic handling of fish products. Fish cutters primarily use manual equipment like sharp knives, cutting boards, and bone saws to trim and section fish accurately. Both roles require specialized gloves and cleaning tools to maintain safety and prevent contamination during fish preparation.

Work Environment and Conditions

Fish processors work primarily in temperature-controlled facilities, handling cleaning, filleting, and packaging of fish with strict hygiene standards to maintain food safety. Fish cutters often operate in similar settings but focus specifically on slicing and portioning fish, requiring precision and manual dexterity. Both roles demand standing for extended periods and can involve exposure to cold, wet, and slippery conditions, emphasizing the need for proper protective gear.

Safety Protocols and Health Standards

Fish processors adhere to stringent safety protocols including regular sanitation of equipment, use of protective clothing, and strict temperature controls to prevent contamination and ensure fish quality. Fish cutters focus on precise knife handling techniques, minimizing cross-contamination risks by maintaining clean cutting surfaces and wearing cut-resistant gloves. Both roles comply with health standards such as HACCP guidelines and regular health inspections to safeguard worker safety and product hygiene.

Training and Certification Requirements

Fish processors require comprehensive training in hygiene, quality control, and safe handling of seafood, often necessitating certification in food safety standards such as HACCP. Fish cutters primarily focus on precise knife skills and fish anatomy knowledge, with certifications typically centered around specific cutting techniques and occupational safety. Both roles benefit from ongoing professional development to maintain compliance with industry regulations and ensure product quality.

Career Advancement Opportunities

Fish processors often have clearer pathways for career advancement through supervisory or quality control roles within seafood processing plants, leveraging their skills in handling, packaging, and preservation techniques. Fish cutters, specializing in filleting and portioning raw fish, may progress by developing expertise in precision cutting or knife skills, potentially moving into training or specialist positions in high-demand market segments. Both careers benefit from certifications in food safety and handling, which enhance promotion prospects and industry recognition.

Salary Expectations and Benefits

Fish processors typically earn an average salary ranging from $25,000 to $40,000 annually, depending on experience and location, while fish cutters often have a lower starting salary between $20,000 and $35,000. Benefits for fish processors usually include health insurance, paid time off, and sometimes bonuses linked to production output, whereas fish cutters may receive fewer benefits but often have opportunities for wage increases with skill advancement. Understanding these differences helps job seekers in the fishing industry make informed decisions about career paths and compensation expectations.

Industry Demand and Future Outlook

The fish processing industry shows growing demand for skilled fish processors who manage cleaning, filleting, and packaging to meet strict quality standards in large-scale operations. Fish cutters, specializing in precise manual or automated cutting of fish, remain essential for ensuring product consistency and minimizing waste, especially in premium seafood markets. Technological advancements and increasing global seafood consumption indicate a robust future outlook, with both roles evolving toward higher efficiency and sustainability.

Fish Processor vs Fish Cutter Infographic

jobdiv.com

jobdiv.com